The Impact of Component Shelf Life on Electronic Devices

Component shelf life is crucial for device reliability. Proper storage, handling, and management prevent failures, ensuring optimal performance and longevity.

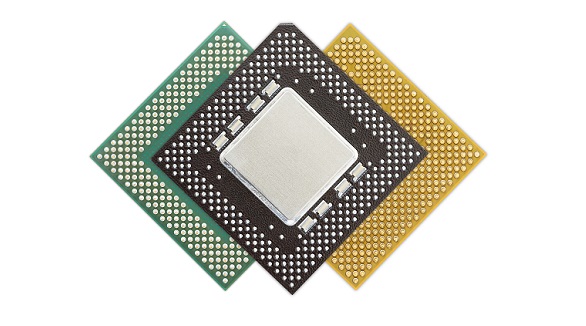

The essential electronic components of modern technology include the building blocks in nearly all devices, ranging from consumer items to the most complex industrial and aerospace applications. As demands for higher performance and greater reliability continue to increase, the shelf life of these components becomes increasingly critical. Generally speaking, shelf life pertains to the period when a component can be stored within specified conditions without deterioration either in quality or performance. This article explains how the shelf life of electronic components impacts the performance of the device and what are some ways to minimize risks related to this.

Shelf life with respect to electronic components is the period they can be stored while still having their functionality preserved. It doesn't really mean that beyond that period, the component stops working, but the efficiency could reduce affecting the reliability of performance.

Key Factors Affecting Shelf Life

Physical Environment: Materials subjected to temperature, moisture, and light may cause a decrease in material components because of processes such as oxidation or corrosion over time. Material Properties: Components are affected by chemical instability of constituent materials; for example, plastics and polymers used in packaging, which influence the lifespan of components.

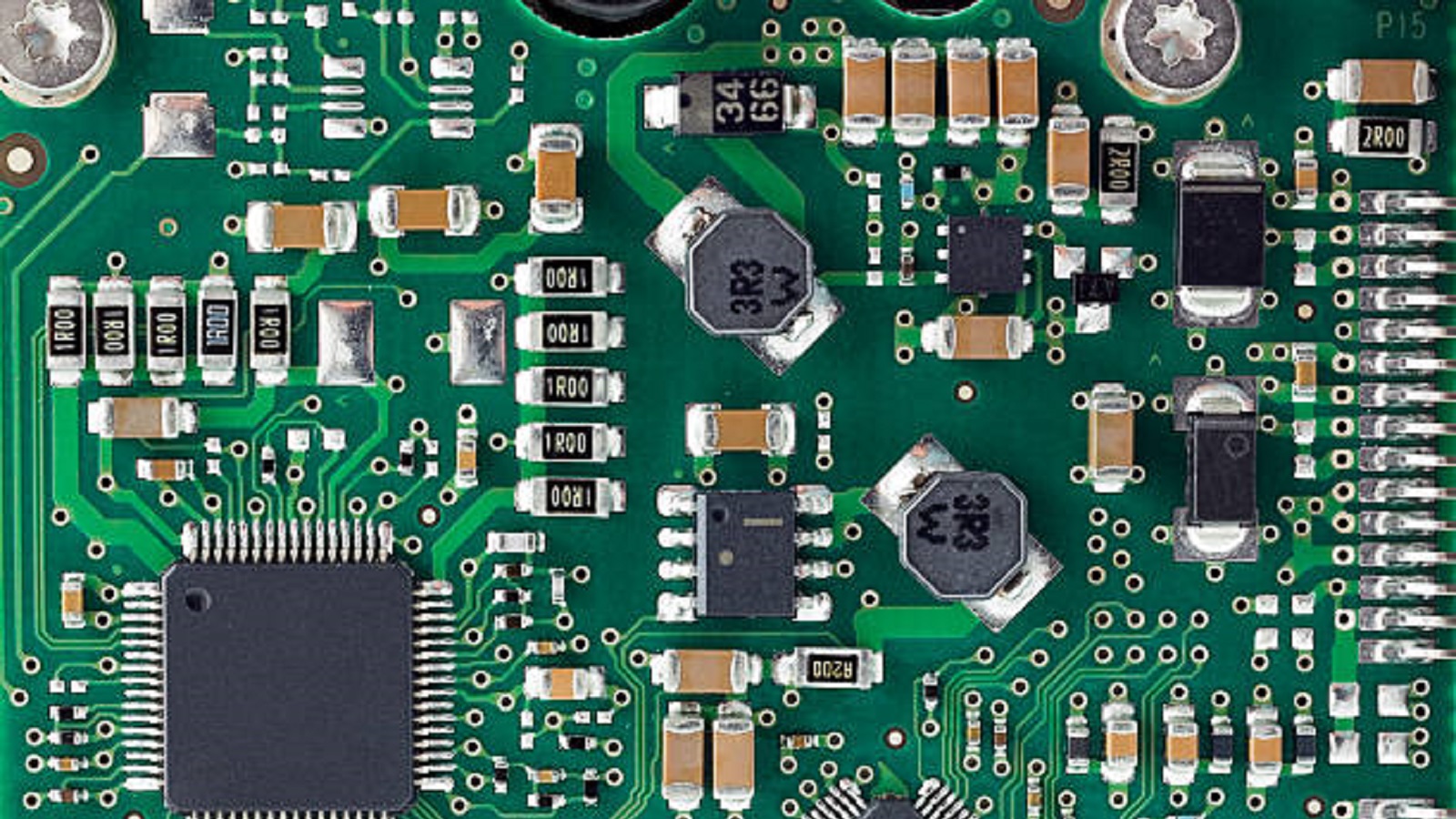

Component Type: Generally speaking, passive components like resistors or capacitors last longer than active components such as transistors or integrated circuits that are more susceptible to environmental factors.

Packaging and Storage: The use of barrier moisture packaging combined with ESD protective measures can extend the shelf life significantly, at times when combined with suitable storage conditions.

How Shelf Life Affects Device Performance

The length of time that components are exposed to the environment will affect performance in several critical ways.

Higher Failure Rates: The failure rate increases with components getting beyond their shelf life. For example, the capacitors may show signs of either leakage or loss of capacitance and hence complete failure, which may be disastrous in power supplies and timing circuits.

Degraded Electrical Characteristics: Prolonged storage can result in changes to electrical parameters, such as resistance, capacitance, and inductance, which in turn affect circuit performance, causing issues like signal loss or increased noise levels.

Compromised Reliability: Using components beyond their designated shelf life undermines the reliability of the whole device, posing serious risks in high-stakes environments such as aerospace, automotive, and healthcare, where device failure may have serious consequences.

Operational Downtime and Maintenance Costs: Devices containing obsolete components need periodic checks of the modules. This makes them susceptible to unplanned downtimes, thus increasing operational expenses and probably a halt in service delivery.

How to Manage Shelf Life

Several strategic actions may be considered in order to minimize the detriments of shelf life on electronic components:

Inventory Management

First In, First Out (FIFO): It helps prevent using older stock beyond its shelf life, hence preventing expired or near-to-expire stock from lying in storage.

Detailed Tracking and Documentation: Detailed records of component purchase dates, shelf life specification, and usage will ensure proactivity in inventory management and decision-making.

Better Storage

Controlled Environment: The use of a climate-controlled environment will block early degradation by maintaining the best temperature and humidity conditions for components.

Advanced Packaging: The utilization of packaging solutions that incorporate moisture barriers and ESD protection extends component usability during long-term storage.

Regular Testing and Quality Assurance

Routine Functional Testing: Periodic functional testing of components in storage to confirm that they will meet performance standards can spot potential problems early.

Constant Quality Inspection: Regular audits on storage practices for conformity with standards catch lapses either in the handling or in the conditions of storage for components.

Supplier Collaboration

Strict Quality Controls: Engage with suppliers to ensure components are manufactured to high standards and suitably packaged to ensure longevity.

Monitoring Obsolescence Risks: Stay updated with the stage of the lifecycle of components to plan the replacement of parts and effectively manage inventories to avoid the obsolescence of any stock.

Technological Advancements Improve Shelf Life

Recent technological developments bring better methods for shelf-life management of electronic components:

Moisture Barrier Bags: Vacuum-sealed bags that prevent oxidation are especially valuable for sensitive components and greatly extend the shelf life of components sensitive to environmental exposure.

Desiccant Integration: Integrating silica gel packets into the packaging to absorb ambient moisture crucially cuts down damage from humidity over time.

Intelligent Inventory Management Systems: Modern inventory systems with real-time environmental sensors maintain detailed environmental logs that help in the accurate tracking of conditions affecting component shelf life.

Handling and Storage Best Practices

The following are general handling and storage best practices to help attain maximum shelf life for electronic components:

Handling Precautions

ESD Protection: The components are susceptible to damage from electrostatic discharge. The use of ESD-safe bags, gloves, and work surfaces minimizes the risks.

Surface Contamination Controls: Gloves, masks, and protective garments are used to avoid contaminants from reaching the component surfaces to retain their integrity and performance.

Storage Guidelines

Packaging Verification: Components should be stored in packaging provided by the manufacturer or additional MBB with moisture indicators so that internal conditions are closely monitored.

Routine Condition Checks: Visually inspect anomalies such as wet packages or corrosions that need immediate evaluation with corrective actions.

Defined Storage Conditions: Controlled storage conditions include maintaining air humidity and storing the components in inert conditions to further help prevent aging or degradation prematurely.

Understanding and managing the shelf life of electronic components is essential to optimal performance and reliability for electronic devices. By understanding the various factors that affect shelf life and using effective management, handling, and storage practices, manufacturers and engineers at PCBX can better protect against component-related failures. These are indispensable practices that, with the growing speed of technological development, are crucial in view of a proactive approach toward sustaining excellence across device functionality. Therein lies the development and application of comprehensive measures necessary to ensure the integrity of electronic components so that such devices will continue to remain relevant for the ever-grown demands of reliability and performance in today's technological world.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Routine inspections and proper maintenance of capacitors and resistors in PCBs reduce failures, prolong device lifespan, and lower maintenance costs.

Capacitors are crucial in circuits for storing energy. Testing methods include in-circuit and out-of-circuit using digital multimeters, ESR, and LCR meters. Proper testing ensures reliability and prevents malfunctions.

IC packaging is essential in electronics for protecting components, providing electrical connections, and managing heat. This tutorial explores its complexities, including its importance, various types like SMD, QFP, and BGA, and considerations for choosing the right package for specific applications. Proper IC packaging enhances PCB performance and reliability.