The Key Factors Influencing PCB Pricing

PCB pricing is influenced by material diversity, production processes, PCB complexity, customer requirements, manufacturer capabilities, payment methods, and geographical location.

For many years, price changes in the PCB have been usual not only for outsiders but insiders in the industry. Nonetheless, even a person with the longest experience in the PCB business may not know all its intricacies. The main factors impacting PCB prices need to be analyzed for better understanding:

Material Diversity

The variation of materials used in making PCBs greatly affects pricing. For standard double-sided boards, FR-4 and CEM-3 are applied quite frequently. Board thicknesses vary from 0.2mm to 5.0mm, and copper thickness ranges from 0.5 to 3oz, which causes a whole variation in material prices. Solder mask inks also present price differences between ordinary thermoset oils and photosensitive green oils, thus adding to the price difference.

Variations of the Production Process

Different production processes cost differently, hence prices vary. For example, gold-plated boards are more expensive than tin-sprayed boards. The processes involved in milling, for instance, are different from those used in the making of stamped, otherwise known as beer boards. The methods used, either silk screen lines or dry film lines, also bring about a lot of price variation.

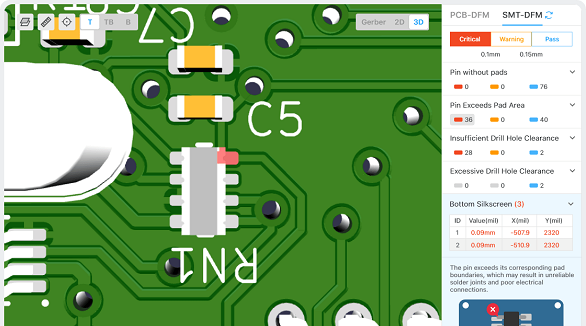

PCB Complexity

Even with the same material used, and process followed, the complexity of the PCB itself will bring about cost differences. For example, even if two boards have a thousand holes, one has a hole diameter over 0.6 mm and another under 0.6 mm in diameter; the drilling costs differ. Similarly, if on one board the line width is above 0.2mm and on the other below, then the production costs will differ. Higher scrap rates due to more complex boards will increase the costs, leading to the price diversification.

Customer Requirements

Different customer requirements directly influence production yields. As such, a board rated under IPC-A-600E Class 1 standards may reach 98%, but under Class 3 standards, the pass rate could be 90%. Such changing yield rates affect manufacturing costs and thus product prices.

Manufacturer Differences

Different manufacturers of PCBs possess different technologies and equipment, so the cost varies even for the same products. For instance, some manufacturers like producing tin-sprayed boards since it involves a relatively straightforward process that is not expensive. Others can produce gold-plated boards even though the rate of scrap is higher, increasing the cost. Hence, the prices for tin-sprayed boards are usually lower than for gold-plated ones.

Payment Methods

Prices may vary due to different modes of payment. Some manufacturers increase the prices between 5% to 10% based on various payment conditions, so these variations increase the price gap.

Geographical or Regional Differences

Geographical area is another reason for price variation. The price goes on increasing from south to north, thus leading to regional price differences. These regional price differences add more to the diversity in PCB prices.

In conclusion, a great number of factors relate to the price of a PCB, such as material choices, the manufacturing process, the complexity of the PCB, customer requirements, manufacturer capabilities, payment methods, and geographical locations. These variables are crucial considerations for purchasing within the PCB market.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCBs (Printed Circuit Boards) are fundamental in electronics, composed of multiple layers like silkscreen, soldermask, copper, and substrate, chosen for specific electrical functions.

The article is developed concerning the breakthrough of integrated circuits and the need for custom PCBs in some electronic products. It enumerates ten golden rules in conducting PCB layout design and manufacturing: grid selection, routing, power layers, component placement, panel duplication, component value combination, frequent DRC, flexible silkscreen use, decoupling capacitors, and pre-production parameter checks. These rules provide for the optimum design and manufacturing of a PCB.

Most electronic circuits are mounted on PCBs, or Printed Circuit Boards, which provide mechanical support and electrical interconnection of electronic components. There are, however, special applications that involve the use of single and double-sided PCBs, multi-layer PCBs, or even rigid and flexible PCBs with aluminum backing, targeting medical, industrial, auto, and aerospace industries. They may use materials such as fiberglass, epoxy, aluminum, and others.