The Role of PCBs in GPUs

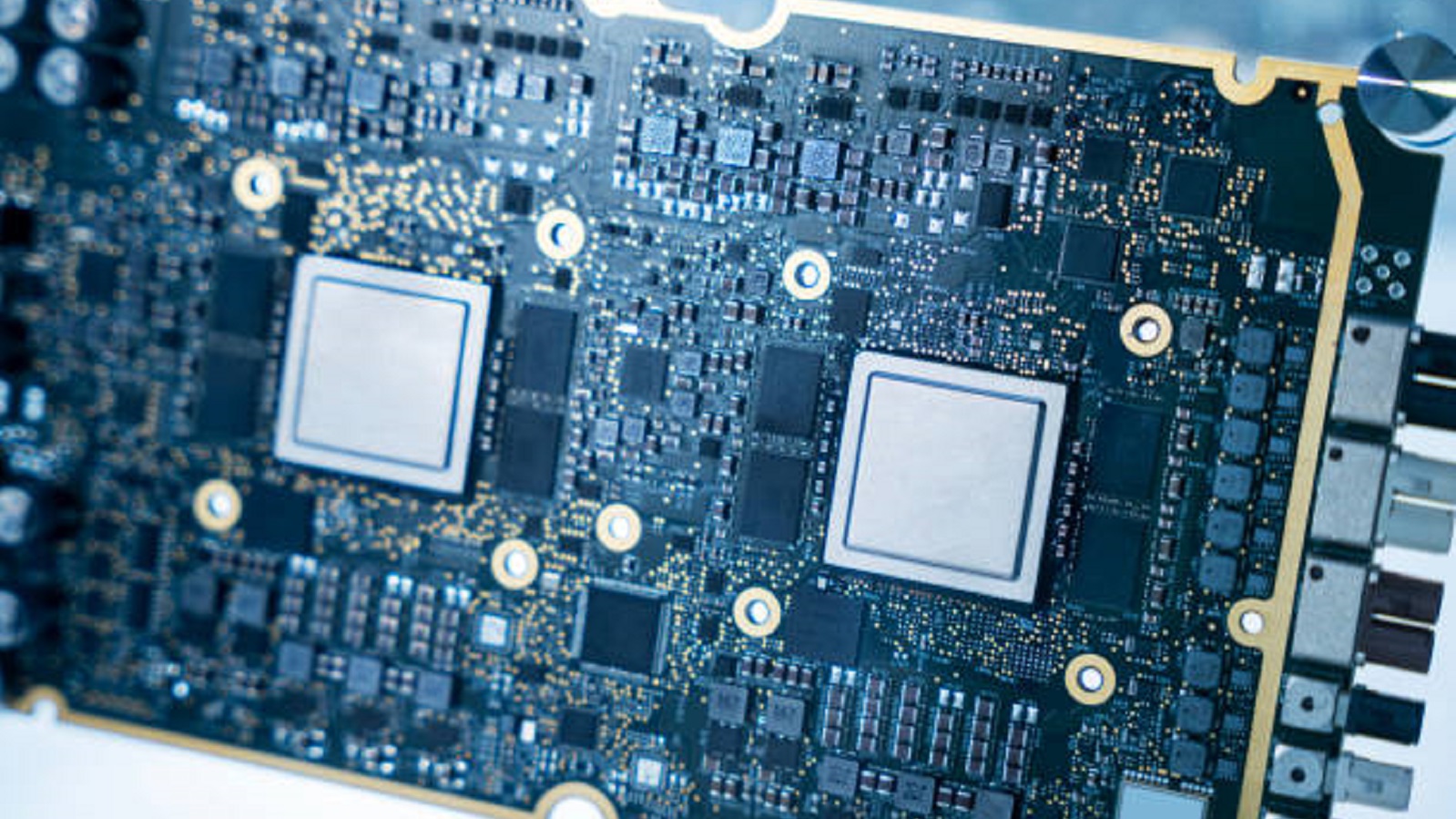

PCBs are crucial in GPUs for mounting components, enabling communication, power delivery, and thermal management, impacting performance and reliability.

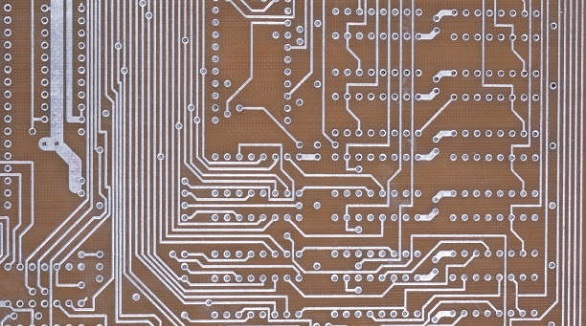

In modern computing and gaming, the GPU is very important for the rendering of quality images and ensuring that there is smooth visual performance. The Printed Circuit Board, or PCB, is an instrumental element at the heart of every GPU; it acts as the backbone that integrates and connects all the critical components. This article explains the function, design, and impact of PCBs within GPUs and how they enable powerful graphic capabilities.

A PCB is a structuring board made of non-conductive material, typically fiberglass, on which conductive pathways are etched. In the case of the GPU, the PCB is much more than a mere base; it is a framework that supports a number of elements that are crucial to the process of graphics processing, including:

Mounting Critical Components

This stability offered by the PCB helps mount and interconnect critical elements: the GPU chip, the memory modules, the power circuitry, the connectors, and the supporting chips that together drive key functionality of the GPU.

To Accomplify Communication

Traces etched in the PCB allow communication among mounted components: between memory and other subsystems within the GPU chip, at high speed with reduced incidence of errors or noise, for data exchange and information transfer.

Power Delivery

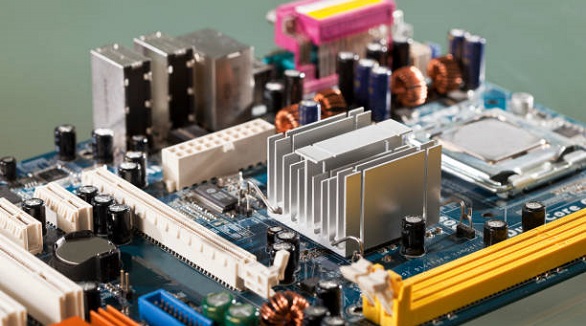

The power circuitry, which also includes voltage regulator modules (VRMs), is combined into the PCB to provide clean, stable power to the various components of the GPU for efficient and reliable operations.

Mechanical Integrity

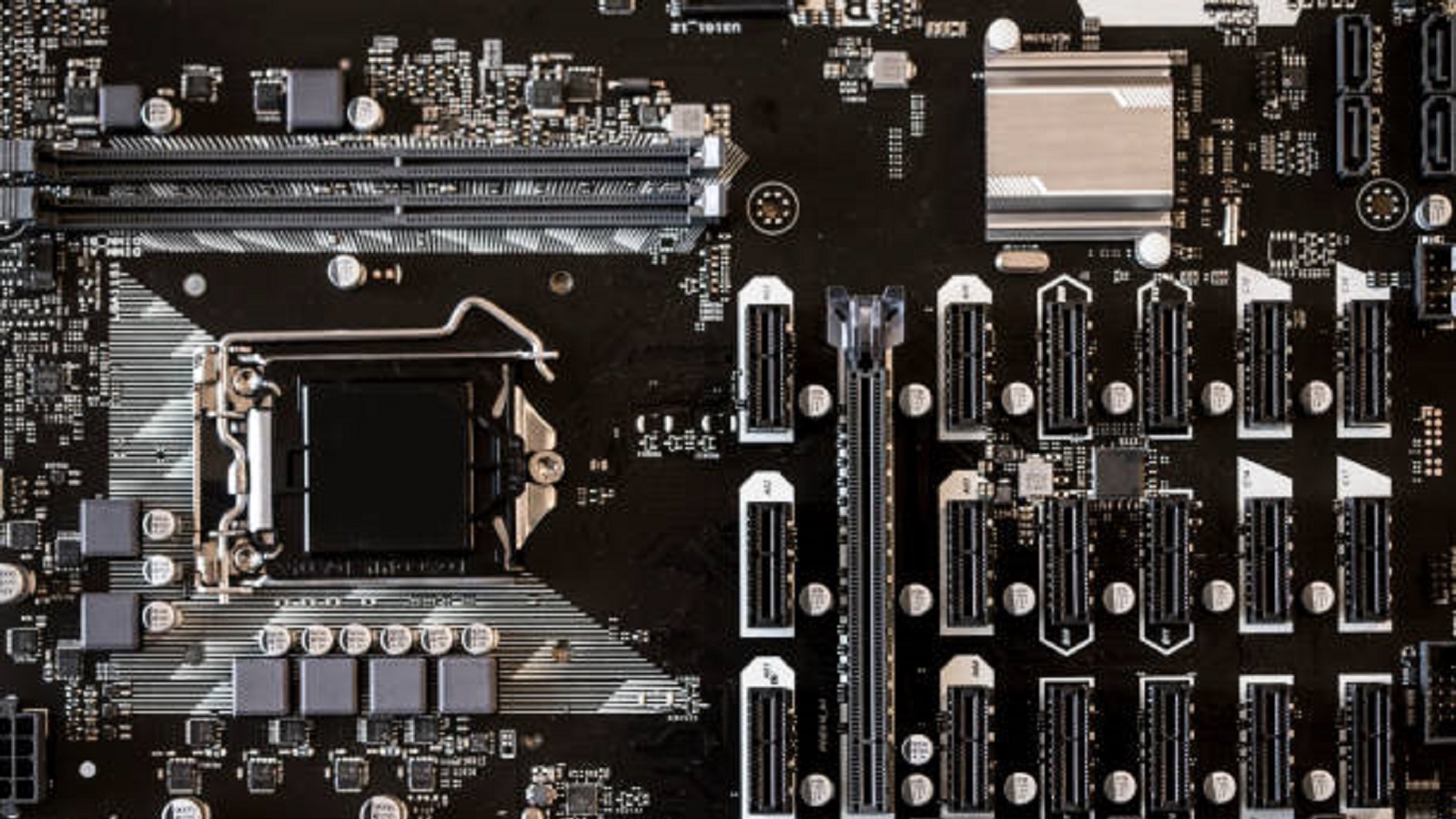

A strong PCB mechanically stabilizes the graphics card during handling and installation; materials such as FR4 fiberglass are commonly used.

Key Design Considerations for GPU PCBs

It requires careful planning to design a GPU PCB for modern graphics cards, which boast of very high performance:

Signal Integrity: In modern times, the working of GPUs at over 1GHz requires careful impedance and trace routing.

Power Integrity: GPUs are power hungry, often more than 100 watts. The PCB should be able to deliver enough power with very low noise and voltage ripples; this requires high-quality VRMs and capacitors.

Thermal Dissipation: The board must dissipate significant heat generated by the GPU chip and power circuitry. It does so through thermal pads, heat pipes, and optimized airflow designs.

Component Placement: Effective component placement affects routing efficiency and thermal management. A complex balancing of all these factors needs to take place in order to achieve higher performance.

Electromagnetic Interference (EMI) Reduction: Proper layer stacking, filtering, and shielding are important in minimizing EMI, thus guaranteeing the stability of performance.

Size and Thickness: The dimensions of the PCB relate directly to the size of the graphics card in general. While thicker PCBs improve power integrity and rigidity, they increase material costs.

Cost Management: Decisions on PCB design have great effects on production cost. A balance must be reached to ensure that the features used to enhance performance do not cut too deeply into profit margins.

PCB Layers and Functionality

Most high-end GPU PCBs have multiple conductive layers for different purposes:

Top/Component Layer: This layer hosts the GPU chip, memory, and most components.

Ground Plane: Offers a low-impedance path for current return.

Routing Layers: Allow component interconnect signaling.

Power Plane(s): Provide power with high ampacity.

Stiffening Layers: Add structural rigidity to prevent flexing of the board.

The Impact of PCBs on GPU Performance and Reliability

PCBs form the foundation of GPU performance: speed, power handling, thermal performance, and reliability:

Speed Preservation: Carefully routed traces maintain signal integrity, supporting stable peak GPU clock speeds.

Power Handling: Robust power delivery systems allow GPUs to draw considerable power while stabilizing component operation.

Thermal Management: Heatsinks, thermal pads, and optimized airflow ensure effective heat dissipation.

Environmental Hardiness: Durable materials and protective coatings withstand thermal stresses over time.

Variations Among GPU Tiers

The complexity of a GPU's PCB varies across product tiers:

Entry-Level GPU PCBs: Basic designs with fewer layers and reduced circuitry have a firm basis on cost efficiency.

Mainstream GPU PCBs: A balance of robustness in the design, with an increase in power phases and circuit protection.

Enthusiast GPU PCBs: High layer counts with advanced materials for maximum performance and overclocking potential.

Real-world examples will show the variation in PCB design and really give a glimpse into the heavy engineering involved in high-performance graphics cards:

Entry-Level: Basic 4-layer PCBs, minimal power phases.

Mainstream: 8-layer designs feature improved power delivery and shielding.

Enthusiast: 10-layer boards boast of extensive power phases and enhanced thermal management.

In short, the PCB is the backbone that turns a raw GPU chip into a complete, workable graphics powerhouse. With a balancing act of design considerations of signal integrity, thermal management, and cost, it is the PCB that will directly influence the performance and lifespan of a GPU. The same applies to the ongoing developments that are required in unlocking ever-higher levels of performance in gaming and graphics.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Burn-in boards are vital for testing semiconductor reliability, simulating stress to reveal defects, ensuring high-quality devices before mass production.

Carrier PCBs are crucial for data modulation, multiplexing, and network integration, supporting efficient and robust telecom infrastructures globally.

Select aluminum PCBs for excellent heat management or FR4 PCBs for cost-effective versatility in diverse electronic applications.