The Significance of Visual Components Assembly

Visual components streamline design and simulation in manufacturing, improving communication, user experience, and efficiency, especially for PCB production.

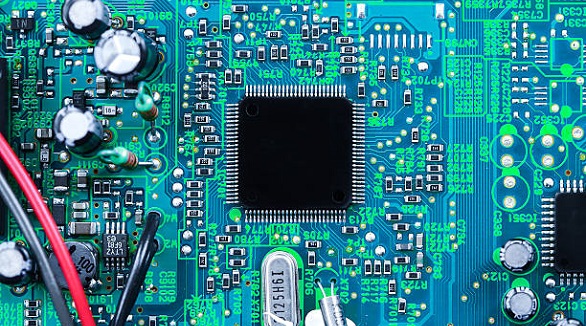

With the way the world is becoming more and more technological day by day, it has become crystal clear how much assembling visual components can help every sector, from software development to digital marketing and most notably in manufacturing environments such as the production of Printed Circuit Boards. This article describes the importance and application of visual components assembly, with special emphasis on platforms like Visual Components, which have facilitated the designing and simulation of manufacturing processes.

The graphical aids and helpers are basically for designing, modeling, and simulating manufacturing processes, while in systems like Visual Components, these include 3D model databases, simulation, and advanced visualization involving industrial equipment, conveyors, and robots. They help the engineer/designer to plan, analyze, and validate complex systems in a virtual environment with much higher efficiency, hence bridging the gap from conceptual design to practical realization.

Improved Communication and Understanding

One of the major benefits of visual components assembly is improved communication. The possibility to import models of huge dimensions and complicated shapes allows for easy transmission of complex ideas. This aspect is highly important in the manufacturing industry, where accuracy and clarity are of essence. Manufacturing teams using 3D simulations can see processes and foresee problems that may arise well before they happen, which goes beyond classic communication limitations and helps avoid mistakes that may cost a lot.

They will also play a critical role in training and education generally in the manufacturing domain, since such visual models make abstract concepts more tangible and, thus, more comprehensible to and communicable by individuals of every level of expertise. This is particularly important in a field like PCB manufacturing, where detailed explanation of the demands for precision needs and understanding is called for.

Improved User Experience and Efficiency

The Visual Components Assembly platform is designed to take user experience to a whole new level by making the UI/UX very intuitive. It uses a familiar ribbon interface where the commands are efficiently laid out to make the engineers and designers quickly find and use new features with ease. It's optimized for a 64-bit Windows environment, including better graphics, faster load times, and a generally improved user experience. This interface is further streamlined, reducing the time and effort required by design and simulation processes.

Smoothening user procedures and workflows, Visual Components Assembly makes sure even large and complex layouts remain flexible to navigate. Further underlined by tools such as the CAD converter, which allows for rapid importation of geometries into the 3D environment, enabling fast prototyping and iteration cycles, this is a fact.

Simplified Development and Cost-Effectiveness

Visual Components Assembly provides a modular and open architecture, which makes it easy to customize and integrate a wide range of visual components. This flexibility is the main reason for minimizing development time, enabling fast prototyping and, consequently, reducing development costs. With an eCatalog containing more than 2,300 predefined components, including conveyors, industrial robots, and other parts necessary for this purpose, the engineer will be able to optimize layouts rapidly without extensive custom development work.

Most especially, the affordability of the platform will help the smaller manufacturing firms that have very tight budgets. The pre-built components and tools in the platform make it easier to develop faster, enabling the company to compete with larger organizations by reducing overhead and accelerating time-to-market for new products.

Advanced Simulation and Process Modeling

Perhaps the most striking feature in Visual Components is its advanced simulation and process modeling. This comprises a set of advanced rendering modes powered by the PhysX engine, visualizing influences of real-world physics like gravity and collisions. These simulations are helpful for engineers to visualize and test in virtual 3D space how processes will work before actual implementation.

Perhaps most importantly, the platform allows for smooth PLC simulation and integration, thereby connecting virtual simulations with real-life applications. It even allows engineers to simulate robotic or logistical systems through plug-and-play, making it an essential tool in automating planning and process workflows. The fact that such simulations can be connected with actual robotics or PLC systems means that such simulations are not just theoretical exercises but a practical prelude to eventual scenarios.

Comprehensive Reporting and Analytics

Data-driven decisions are an intrinsic part of the manufacturing industry these days. Consequently, Visual Components Assembly allows the easy creation of advanced analytics and visualization in a multitude of formats, such as line, bar, area, or pie charts. Visualizations support detection of bottlenecks in production and performance variations that will guide more strategic decisions.

Besides, simulated data can be easily exported into popular formats such as Excel or PDF for deeper analysis and reporting. The holistic approach of this lets the stakeholders visualize several dynamics related to the production line and make decisions based on quantitative insights.

Visual assembly plays an important role in modern manufacturing and design, helping engineers and designers streamline processes, enhance user experience, and effectively communicate. Visual Components and similar platforms hold the key to industries in providing tools that will enable them to efficiently design and simulate complex manufacturing processes, which are needed in industries such as the production of PCBs. As technology continues to evolve, the need for virtual simulation and optimization of manufacturing environments will only increase, making visual components assembly a cornerstone of modern industrial operations. To companies like PCBX, these sophisticated technologies remain the significant key to competitiveness in today's fast-moving manufacturing world.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Effective electronic packaging ensures protection, efficiency, and reliability, minimizing risks from environmental hazards and supporting manufacturing processes.

Routine inspections and proper maintenance of capacitors and resistors in PCBs reduce failures, prolong device lifespan, and lower maintenance costs.

Effective PCB design ensures reliable electronics by optimizing component placement, connections, and testing, enhancing performance and longevity.