Understanding Current Ratings and Limits in PCBs

Understanding PCB current ratings ensures safe electric flow. Optimize trace size, copper weight, and use via calculators and high-current connectors for efficient and reliable PCB designs.

Printed Circuit Boards, or PCBs for short, form the backbone of most modern electronic devices in the world today. They provide the physical platform for electronic components and offer electrical connections between them. However, for optimal performance and durability, there is always a need to understand the current ratings and limits that may exist in a PCB. This article will walk you through the key issues associated with current ratings from a PCB point of view, the importance of using a PCB via current calculator, and the role of high-current PCB connectors.

What are the Current Ratings of PCB?

The current ratings of a PCB refer to the maximum quantity of electrical current that can safely flow through the traces, vias, and other conductive paths on the board without overheating or sustaining any form of damage. These ratings are very important since exceeding them will cause the board to overheat and get damaged.

Factors Affecting PCB Current Ratings

Current rating is decided by several factors in a circuit board, such as

Trace Width and Thickness: The wider and thicker the trace, the more current it can carry due to the wider surface area it provides for cooling.

Copper Weight: It is measured in ounces per square foot. It determines the level of current a trace can carry. Thicker copper carries more current.

Temperature Rise: Current passing through the PCB generates heat. It is required to make sure that temperature rises to the safe limit to ensure integrity on the board.

Environmental Conditions: Some of the environmental factors that may affect the current-carrying capability of a PCB include ambient temperature and airflow.

PCB Via Current Calculator

Vias are small conductive holes used to connect different layers of the PCB. Calculating their current capacity is crucial in the case of multi-layer boards where interlayer connections are also frequent.

Importance of Using a PCB Via Current Calculator

A PCB via current calculator helps engineers specify how much current can safely pass through a via. Here's why it's important:

Prevents Overloading: By correctly estimating the current capacity, it will help the vias not be overloaded; thus, it doesn't lead to board failure.

Optimizes Design: Knowledge of the limit encourages better design decisions to make sure the board supports expected electrical load.

Ensures Reliability: Proper calculation of vias contributes to the general reliability and durability of the PCB by reducing chances of failure overtime.

How to Use a PCB Via Current Calculator

Although different calculators can have some specific inputs, in most cases the common parameters of input include:

Via Diameter: The width of a via influences its current capacity.

Plating thickness: The thickness of the conductive plating within the via

Temperature rise: The allowable temperature increases due to current flow

With these inputs, the calculator will provide the estimated value of the maximum current a via can carry.

High current PCB Connectors

The proper selection of PCB connectors becomes a critical issue for applications in which high electric currents must be transmitted. High-current PCB connectors are produced to bear high current values without overheating or failure.

Features of High Current PCB Connectors

High-Density Construction: Materials that provide resistance to high temperatures and mechanical stress are used in such connectors.

Low Electrical Resistance: High-current connectors possess low resistance to minimize power losses and the resultant heat generation.

Secure Attachment: They offer a reliable and secure attachment to the Printed Circuit Board, ensuring stability in performance.

Applications of High Current PCB Connectors

High current PCB connectors find their application in:

Power Supplies: Efficiently distribute and safely handle power.

Industrial Equipment: Heavy machinery relies on them for proper electrical connection.

Automotive Electronics: On board vehicles, where appropriate current distribution is vital.

Designing for Optimal Current Handling

Safe operation and efficiency in a PCB highly depend on consideration for current ratings and limits. Here are some tips that one could consider in designing a PCB with considerations on current rating:

Choose the Right Materials

Selection of the right copper weight and trace width and thickness is just foundational steps in designing the board able to accommodate the expected current.

Consider Thermal Management

Employ good thermal management practices, including adding a heat sink or following good practice with air convection, to keep temperatures on the board within a safe range.

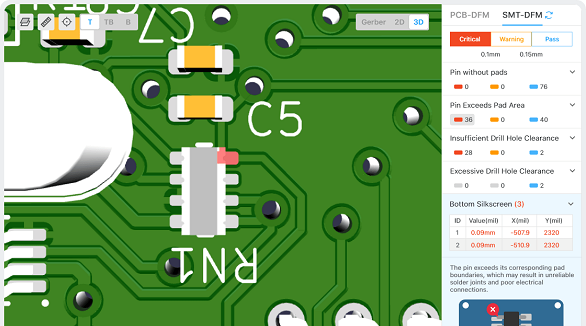

Use Simulation Software

Leverage simulation tools within design software to model current flow and temperature distribution across the PCB. It will allow you to take any possible issues into consideration before manufacturing.

Collaborate with Experts

If you are not sure about your design's current handling capabilities, consultation with PCBX, our experienced designers are always ready to help you.

Conclusion

It enables one to design a reliable and efficient circuit by understanding how to calculate the current ratings and limits on a PCB. Considering trace width, copper weight, and support with calculators such as a PCB via current calculator enhances your design for performance. Proper selection of high-current PCB connectors will also ensure that your board is capable of sustaining applications requiring demanding power. Equipped with this knowledge, you're off to designing your PCB, which can safely meet your project's electrical requirements.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCBs are essential for organizing information and power flow in electronic devices, benefiting from flexibility, durability, safety, efficiency, and heat management.

PCBs (Printed Circuit Boards) are fundamental in electronics, composed of multiple layers like silkscreen, soldermask, copper, and substrate, chosen for specific electrical functions.

The article is developed concerning the breakthrough of integrated circuits and the need for custom PCBs in some electronic products. It enumerates ten golden rules in conducting PCB layout design and manufacturing: grid selection, routing, power layers, component placement, panel duplication, component value combination, frequent DRC, flexible silkscreen use, decoupling capacitors, and pre-production parameter checks. These rules provide for the optimum design and manufacturing of a PCB.