Understanding PCB Effective Thermal Conductivity: A Key to Optimal Thermal Management

Effective thermal conductivity is crucial in PCB design for heat management. It depends on factors like component size and thermal vias, aiding reliable, efficient electronic operation through modeling and analysis.

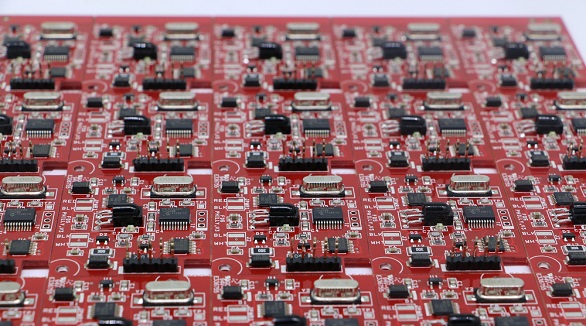

Effective thermal conductivity is a very important parameter in the field of PCB design. It stands for the degree of effectiveness with which the heat is transferred inside a circuit board. At PCBX, we are committed to the optimization of such parameters, purposed on ensuring our clients' electronic design products are reliable and efficient. This article is about the concept of PCB effective thermal conductivity, the factors influencing this property, and its implications in thermal modeling and analysis.

What is Effective Thermal Conductivity?

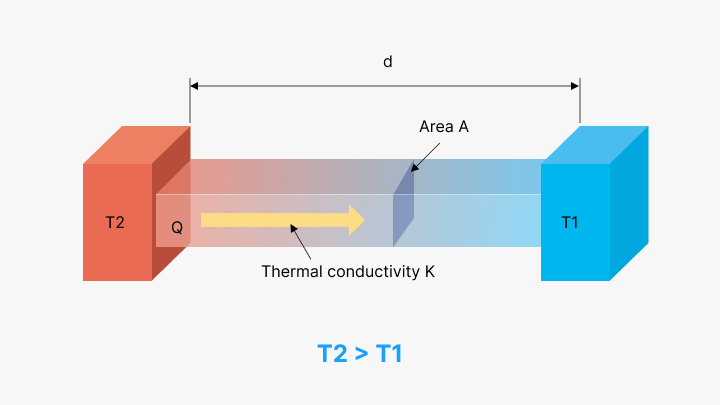

It is defined as the capability of any material or structure to conduct and transfer heat energy through it. For a PCB, it would mean the efficiency with which a board is able to dissipate the operational heat that is being produced by the board components to the ambient surrounding environment. It has the symbol, k((eff)) and the unit of watts per meter-kelvin W/m·K, and this parameter is used for predictions of the thermal performance for a populated PCB.

Why Is Effective Thermal Conductivity Important?

Thermal conductivity is part of thermal modeling and analysis in PCB design. With the current trend of shrinking electronic modules, their efficient heat dissipation challenge grows increasingly critical. Precise prediction of a PCB's heat conducting characteristics will allow designers to preclude thermal problems that affect device reliability and lifespan.

Factors Influencing PCB Effective Thermal Conductivity

The effective thermal conductivity of a PCB depends on quite a few factors. Each factor leads to the result-that is, whether the heat is being managed properly inside the board.

Component Size

Smaller components have reduced capability to dissipate the heat naturally. For example, a MOSFET in SOT-23 package has a lesser heat dissipation area than that in a TO-220 package. Therefore, the size of the components in a PCB makes them directly related to its thermal conductivity.

Thermal Vias

Thermal vias are strategically placed holes designed to facilitate heat dissipation from components. The more thermal vias, the higher effective thermal conductivity, since these add methods for heat to dissipate much as vents let steam out of a container.

Internal Layers

The copper internal layers significantly affect the dissipation of heat. Copper's thermal conductivity is around 355 W/m·K, which is substantially greater than the 0.25 W/m·K FR-4 material. Multilayered PCBs with a substantial amount of copper will result in better thermal performance when used together with thermal vias capable of conducting heat efficiently to the layer.

Copper traces in the PCB serve as one of the major elements of thermal management. Continuous traces from one end to the other ensure higher thermal conductivity. On the other hand, the traces are not continuous in real PCB designs and may result in lower effective thermal conductivity.

Effective Thermal Conductivity in Thermal Modelling

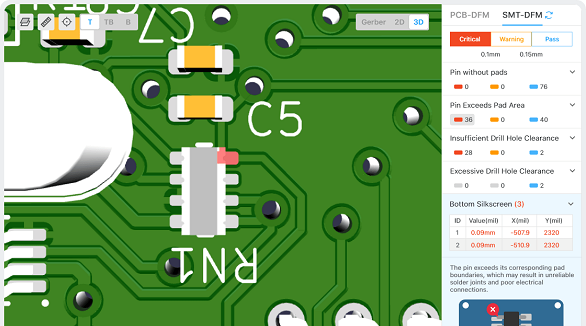

The reason why the effective thermal conductivity is preferred in thermal modeling is the simplicity of computation it offers. Precise thermal prediction of PCBs, especially multi-layered ones, is quite problematic because they are not homogenous. Variability in the component layout, copper planes, vias, and pads across the layers introduces complexities in thermal behavior assessment.

Furthering the cause of achieving higher accuracy, advanced modeling techniques involve profiling each layer of the PCB individually and performing an analysis of pixelated surface data. This, while being more detailed, the selection of software tools in thermal modeling becomes an equally relevant issue.

Software Recommended for Thermal Analysis

OrCAD and Sigrity PowerDC: These are some of the best tools that can be used to carry out detailed thermal analysis in PCB design to predict thermal behavior and its management by designers.

InspectAR: This augmented reality helps in the process of inspect, debug, rework, and assembly of the PCBs, making them more interactive and accurate to enhance the design.

Conclusion

Effective thermal conductivity is one of the fundamentals that have made PCB design ensure efficient thermal management for reliable electronic operation. Advanced thermal modeling and analysis at PCBX are employed to optimize the PCB thermal performance due to the complexity introduced through modern high-density designs. Understanding and accurate modeling of effective thermal conductivity enable delivery of robust and high-performance PCBs, meeting exactly the stringent thermal requirements of our clients.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Designing a PCB involves ten detailed steps: schematic capture, creating a blank PCB layout, syncing designs, defining stackup, setting design rules, placing components, adding drill holes, routing traces, labeling, and generating output files. These steps ensure an organized, error-free process from concept to manufacturing.

The article is developed concerning the breakthrough of integrated circuits and the need for custom PCBs in some electronic products. It enumerates ten golden rules in conducting PCB layout design and manufacturing: grid selection, routing, power layers, component placement, panel duplication, component value combination, frequent DRC, flexible silkscreen use, decoupling capacitors, and pre-production parameter checks. These rules provide for the optimum design and manufacturing of a PCB.

Thermal management is all about more than just keeping the temperature of electronic systems and printed circuit boards low. It has been a key issue related to reliability and performance. Of the very basic fundamentals that would be studied in the field, some are concerned with methods of heat transfer. These are through conduction, convection, and radiation. The methods of cooling include natural cooling, forced-air cooling, fluid cooling, and evaporation cooling. Appropriate thermal design rules shall be followed wherein the chosen materials provide optimum thermal conductivity and the components of a system are so laid out that no hot-spotting will take place. Thermal analysis becomes critical in pointing out heat-related issues and optimizing the design. It thus minimizes failure rates and enhances stability and functionality of the electronic systems through comprehensive thermal management.