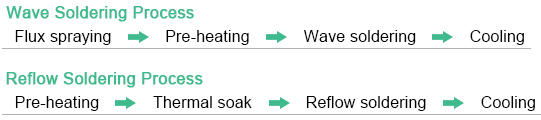

Comparison between Wave Soldering and Reflow Soldering

Soldering forms a very important part in the assembly of a PCB. Wave soldering is ideally applied in Through-Hole Technology, while reflow soldering in Surface Mount Technology. Wave soldering involves flux spraying, pre-heating, soldering, and cooling, while in the case of reflow soldering, pre-heating, thermal soak, soldering, and cooling steps are applied. Temperature and time control are the two most critical parameters in the above-mentioned techniques for ensuring soldering reliability.

Lighter, faster, and more efficient designs are the aims of contemporary electronics, so as PCBA. Since electrical connectivity is achieved only through proper soldering, soldering has played a very important role in the success of electronic products. While hand soldering is still very popular among hobbyists, the high accuracy, higher speed, and cost-effectiveness for large production runs make automatic soldering widespread. Wave soldering and reflow soldering are two confusing soldering processes that frequently lead to misconceptions regarding their proper uses.

Background

Before comparing wave soldering and reflow soldering, it is important to clarify the differences between soldering, welding, and brazing.

Welding is essentially the process of melting two comparable metals together to form a bond. Brazing, on the other hand, involves heating and melting a filler alloy at high temperatures to unite two pieces of metal. Soldering, on the other hand, is a low-temperature brazing process that employs a filler known as solder.

Soldering for PCB Assembly

Solder paste is commonly used for this operation in PCB assembly. Based on the final product needs and any regulatory limits, use either lead or lead-free solder paste.

Wave Soldering

- Definition

In wave soldering, PCBs and materials are bonded together using a liquid "wave" of molten tin from wave soldering equipment. This machine is motor agitated.

- Soldering Process

The entire wave soldering process consists of four steps: flux spraying, pre-heating, the wave soldering process itself, and cooling.

- Flux Spraying: The metal surface must be cleaned, and it is the function of the_flux to remove any oxides and thus prevent further oxidation. The flux also reduces surface tension and conveys or transfers heat.

- Preheating: It involves the movement of a pallet with PCBs through a heat tunnel for flux activation and other purposes to ready the process for soldering.

- Wave Soldering: Out of this solder paste, a wave is made by the rising temperature, which allows for the movement of the PCBs from above it to bind the components with the boards.

- Cooling: The soldering process follows a temperature profile whereby it cools to room temperature to form a solid solder.

Effective time and temperature control is very essential in wave soldering and requires professional-grade machines and skilled PCB assemblers who understand clearly the parameters.

- Application Field

Wave soldering is suitable for Through-hole Technology, Dual In-line Package assembly, and Surface Mount Technology although it is more common in THT.

Reflow Soldering

- Definition

Reflow soldering is a technique for permanently bonding components to their appropriate pads on a PCB. This process includes melting the solder paste in a reflow soldering oven, often using hot air or thermal radiation.

- Soldering Process

The process of reflow soldering consists of the following steps:

- Pre-heating: Evacuates the volatile solvents contained in solder paste and sets a constant temperature.

- Thermal Soak: The flux inside the solder paste becomes activated while temperature slowly rises.

- Reflow Soldering: This is the peak temperature at which solder alloy inside the solder paste melts and bonds the components onto pads.

- Cooling: Solder solidifies as temperature goes down.

- Field of Application

Reflow soldering is mainly used for SMT but applies to some THT assembly techniques such as the Pin-in-Paste soldering.

Wave Soldering vs. Reflow Soldering

- Soldering Process

- The main difference between wave and reflow soldering is flux spraying, which forms part of the wave soldering process. In both methods, temperature and time must be controlled strictly to ensure the flux is appropriately activated.

- Soldering Reliability

- Both methods can lead to soldering defects, which can only be reduced by working according to professional standards and with highly trained and skilled operators.

- Selection Standard

- Generally speaking, reflow soldering is suitable for SMT and wave soldering for THT or DIP assembly. Mixed-assembly boards require SMT first to be followed by THT or DIP so as not to cause the reflow of the solder.

PCBX: Your Partner in PCB Assembly

With over two decades of experience, PCBX can cater to varied requirements of PCB assembly, be it through-hole, SMT, or mixed assembly. Fast Inquiry Contact us now to request a FREE PCBA Quote!

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Surface Mount Technology (SMT) revolutionized electronics, facilitating smaller, faster, and more reliable products. It mounts components directly on PCBs, enabling miniaturization and automation. Though SMT boosts space efficiency, cost-effectiveness, and reliability, it poses rework challenges and requires high initial investment.

The article provides a step-by-step guide to soldering a PCB, covering workspace setup, essential tools, and safety measures. It explains heating the soldering iron, applying flux, tinning the iron tip, placing components, heating joints, applying solder, cooling, inspecting, and cleaning. Emphasis is on practice and safety for successful soldering.

Most electronic circuits are mounted on PCBs, or Printed Circuit Boards, which provide mechanical support and electrical interconnection of electronic components. There are, however, special applications that involve the use of single and double-sided PCBs, multi-layer PCBs, or even rigid and flexible PCBs with aluminum backing, targeting medical, industrial, auto, and aerospace industries. They may use materials such as fiberglass, epoxy, aluminum, and others.