What's the Difference Between Prepreg and Core in PCB Manufacturing?

Understanding core and prepreg materials is crucial for PCB performance and manufacturability. Core provides stability and dielectric properties, while prepreg binds layers. Both affect signal integrity, mechanical stability, and thermal performance.

It would seem that understanding the materials used in construction is very hinged in the world of Printed Circuit Boards, especially as it pertains to performance and manufacturability. Among the variety, two of the most discussed are "prepreg" and "core." While they may sound almost synonymous at first thought, they have different purposes and properties that affect the finished product. It de-mystifies the differences between prepreg and core materials in the manufacturing of printed circuit boards, bringing closure to someone keen on optimizing their design processes. The underlying concepts are presented in the construction of a printed circuit board.

The Basics of PCB Construction

Before diving into the details of prepreg and core materials, a little understanding of how PCBs are constructed should be gained. A typical construction of a PCB stack-up would contain several layers of different materials, each contributing properties and functionality. Core and prepreg materials are the elemental basics that help in adding electrical and mechanical characteristics to the board.

PCB Core: The Foundation

Definition and Structure:

The core of a PCB consists of a solid laminate with one or more layers of prepreg that have been pressed, hardened, and cured. This rigid structure is normally clad with copper foil on either side, which serves as the main conductor for electrical signals.

Material Compositions:

The core material is usually a glass weave impregnated with resin; often FR4, which is a common type of glass-reinforced epoxy laminate. This resin in the core is fully cured, hence providing mechanical stability and a fixed dielectric constant that is really essential for consistent electrical properties.

Functionality:

The main purpose of the core is to provide a stable base on which additional layers build. In actual PCB manufacturing, copper foil on core is etched into required circuitry, which then becomes part of final layer structure.

Electrical Parameters:

The amount of resin, the type of resin, and the glass weave pattern all contribute to determining the dielectric constant of the core. These are key variables, above all for designs that require tight impedance matching and signal integrity-control, which is very often critical at high frequency .

Prepreg: The Glue that Binds

Definition and Structure:

Prepreg (short form for pre-impregnated) is a composite material including a glass fiber weave impregnated with a partially cured (B-stage) resin.

Material Composition:

Like the core, the prepreg material has glass weave impregnated therein, but with resin that is partially cured. That way, the resin can flow and cure fully during lamination, forming strong bonds between adjacent layers.

Functionality:

Prepreg serves a dual purpose. It is an insulation between the conductive layers of copper and an adhesive as well. Prepreg laminates undergo a lamination process in which they are subjected to heat and pressure. It results in resin flow, filling the gaps and gluing the layers.

Structural Considerations

Dielectric Constants:

Both core and prepreg materials exhibit dielectric properties that impact signal propagation. These are normally different in core versus prepreg due to differences in resin content and glass weave tightness. Hence, for designs requiring tight impedance tolerances, this is very significant.

Lamination:

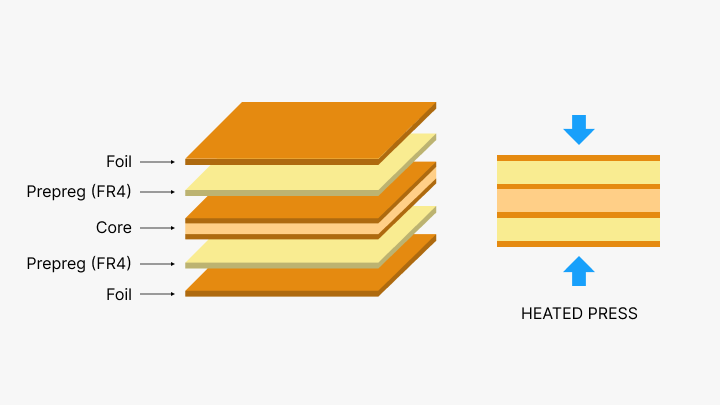

What it would be most befitting, regarding the lamination process, is the unique role of the prepreg. The partial hardening of resin during manufacture melts and flows under heat and pressure, subsequently serving to bond well between the core and conductive layers when hardened. This also affects the final board thickness due to the resin filling up the voids created by etching.

Design and Manufacturing Implications

Stack-Up Configurations:

There are two major approaches to the PCB stack-up configurations:

Some methods are as follows:

Foil Build: In this, the layers of prepreg are overlaid over one another in such a manner so as to sandwich a core at the center of the board. These iterate outward to either surface, with each ending in foil layers. This is the most common method and allows a variety of thickness without adding extra electrical layers that may involve more cost.

Core Build: This is a technique where the prepreg layers are sandwiched in the center of the board, with cores on either side, and iterated toward the surfaces. Sometimes referred to as 'capped' constructions, these core builds tend to offer better performance in microwave applications due to the core material's dielectric properties.

Material Compatibility:

Not all prepreg and core materials are compatible. Differences in dielectric constants between adjacent layers can make precise impedance control difficult. Some combinations of materials may not bond properly during lamination with possible consequences on the board's structural integrity.

Advanced Considerations

Fiber Weave Effects:

This may be due to the inconstancies of both core and prepreg material on glass weave patterns, such as tight versus loose weaves, for example. Inconsistencies between 7628 prepreg and 1080 prepreg. These fiber weaves create uneven signals owing to signal skew besides inducing impedance changes, especially at high frequency.

Creepage and Leakage Current:

One of the most important factors in high voltage applications is the creepage and leakage currents. The dielectric materials involved in this process should, to a large extent, provide resistance to electrical conduction across the board, which might result in failures. Creepage may come as a result of electromigration of copper or even growth of conductive filaments, and specifications for FR4 are devised with such problems in mind.

Practical Applications

Signal Integrity:

Optimal signal integrity requires proper selection and balancing of core and prepreg materials for congruent electrical properties. This is particularly crucial for designs at GHz frequencies, where minor variations in dielectric properties can greatly affect signal performance.

Mechanical Stability:

Selection and configuration of core and prepreg materials also influence the mechanical stability of the overall PCB. The cured resin in the core acts as a rigid base, while the prepreg maintains consistency in bonding layers together.

Thermal Performance:

Another factor is the resilience to temperature. Advanced resins have a higher decomposition and glass transition temperature compared to the traditional DICY resins, such as the phenolic types used on some FR4 cores. Therefore, they are better suited to applications which require high temperatures or that are thermally demanding.

Conclusion

Understanding the various differences and different roles of both core and prepreg PCB materials is basic to any designer's goal of optimizing a board for performance and manufacturability. While the core supplies mechanical stability with a consistent dielectric base, the prepreg serves as the versatile adhesive and insulating layer responsible for layering and bonding. A proper balance between these indeed results in better electrical performance, greater durability in its mechanical properties, and an overall improvement in functionality of the final product in a PCB.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Pads and vias are crucial for PCB design: pads serve as soldering points for components, while vias connect different layers. Understanding and correctly implementing them ensures reliable, efficient, high-performance PCBs.

PCBs are essential for electronic devices, providing mechanical support and electrical connections. This article explores the importance of PCB panel dimensions, standard sizes, and optimization techniques. Key points include cost-efficiency, ease of manufacturing, quality control, and optimal layouts. Factors like board size, volume needs, and equipment capabilities influence panel size. Coordination with manufacturers, using design software, and employing standard sizes can enhance production efficiency and quality.

PCBs (Printed Circuit Boards) are fundamental in electronics, composed of multiple layers like silkscreen, soldermask, copper, and substrate, chosen for specific electrical functions.