What Are the Advantages of SMD Resistor?

SMD resistors are crucial for modern electronics, enabling compact, high-density designs, efficient automated manufacturing, and improved high-frequency performance, driving technological advancement.

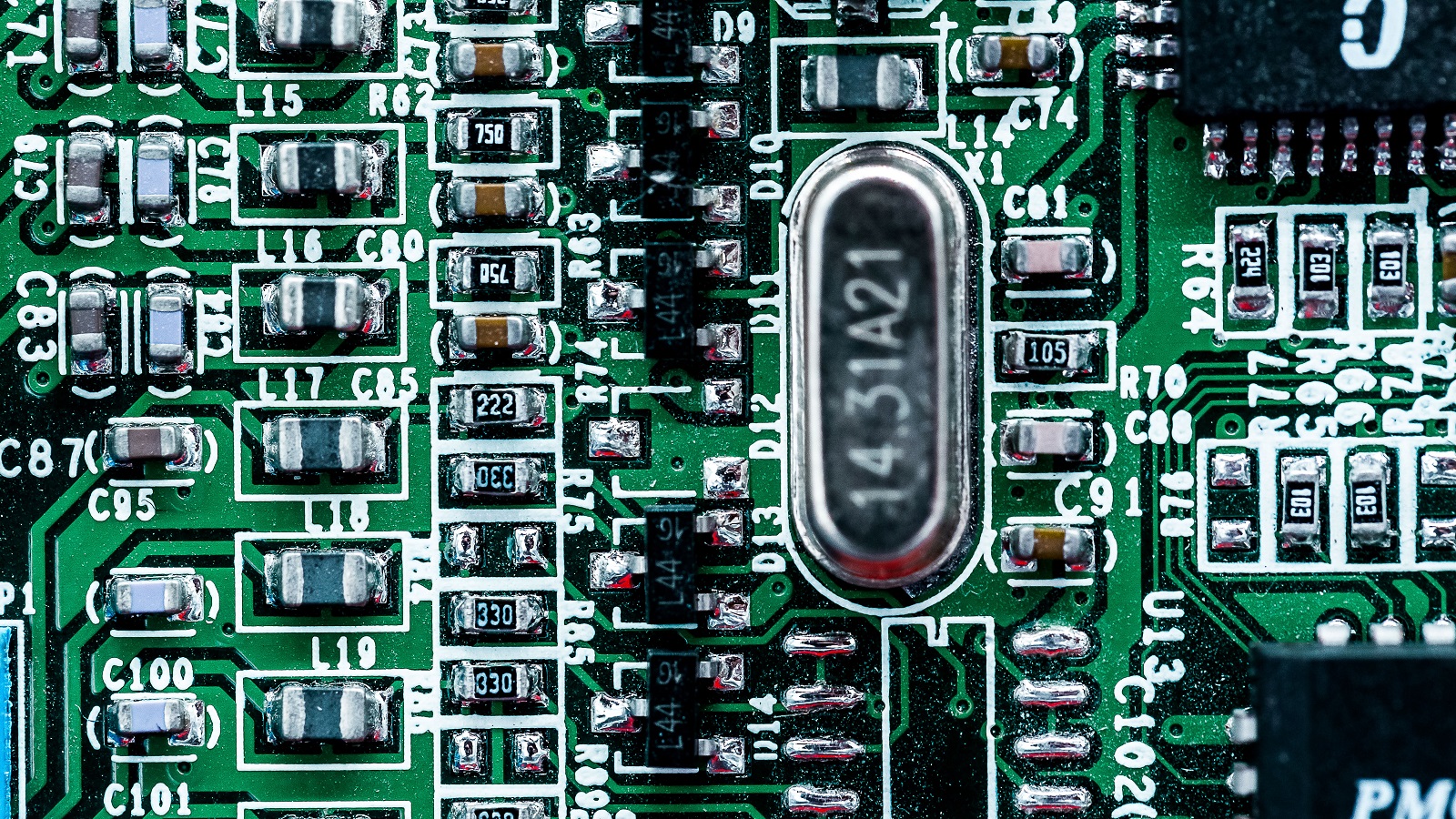

SMD resistors are the most critical parts of today's electronic assemblies. Unlike through-hole resistors, which require leads to be inserted into drilled holes on a printed circuit board, SMD resistors mount directly onto the surface of the PCB. It changes not only the physical design and assembling of electronics but offers many advantages in both technological and economic perspectives; thus, it helps drive the evolution of modern devices.

Miniaturization and Saving Space

One of the most attractive benefits that come with SMD resistors is their small size. With gadgets getting smaller and more compact in these present times, the demand for making such a dream possible with their larger number in the same area has grown remarkably. The SMD resistors satisfy this by accommodating more in one piece of a PCB and thus allowing compact and complex designs to be accommodated. For example, this allows for smaller-sized wearables, smartphones, and other portable technologies without the loss of functionality. This also helped manufacturing companies to shrink their devices along with a greater number of features that greatly improved the user experience and the capability of the device.

High Component Density and Design Flexibility

Due to the tiny footprint, SMD resistors allow more component density on a PCB. The added advantage in the advanced application of electronic devices is the capability to reduce it further in smartphones, laptops, and IoT devices since the use of every millimeter on the board serves to add some value. Higher density contributes to complex circuit designs in smaller areas, hence improving the powers and efficiencies of the device but still keeping it compact. Moreover, flexibility in design allows engineers to explore innovative configurations that were earlier considered very difficult or unfeasible to build using larger, through-hole components.

Performance at High Frequencies

At the technical level, SMD resistors are much better performers than their through-hole brethren for high-frequency work. The traces are much shorter because there are no leads; this means parasitic inductance and capacitance is so low that it assists RF circuits or high-speed signal processing, wherein critical performance at a higher frequency will be important. The improved performance at these frequencies makes SMD resistors ideal for modern communications equipment, including 5G technology, where precision and clarity of signal transmission are paramount.

Automated Manufacturing and Cost Efficiency

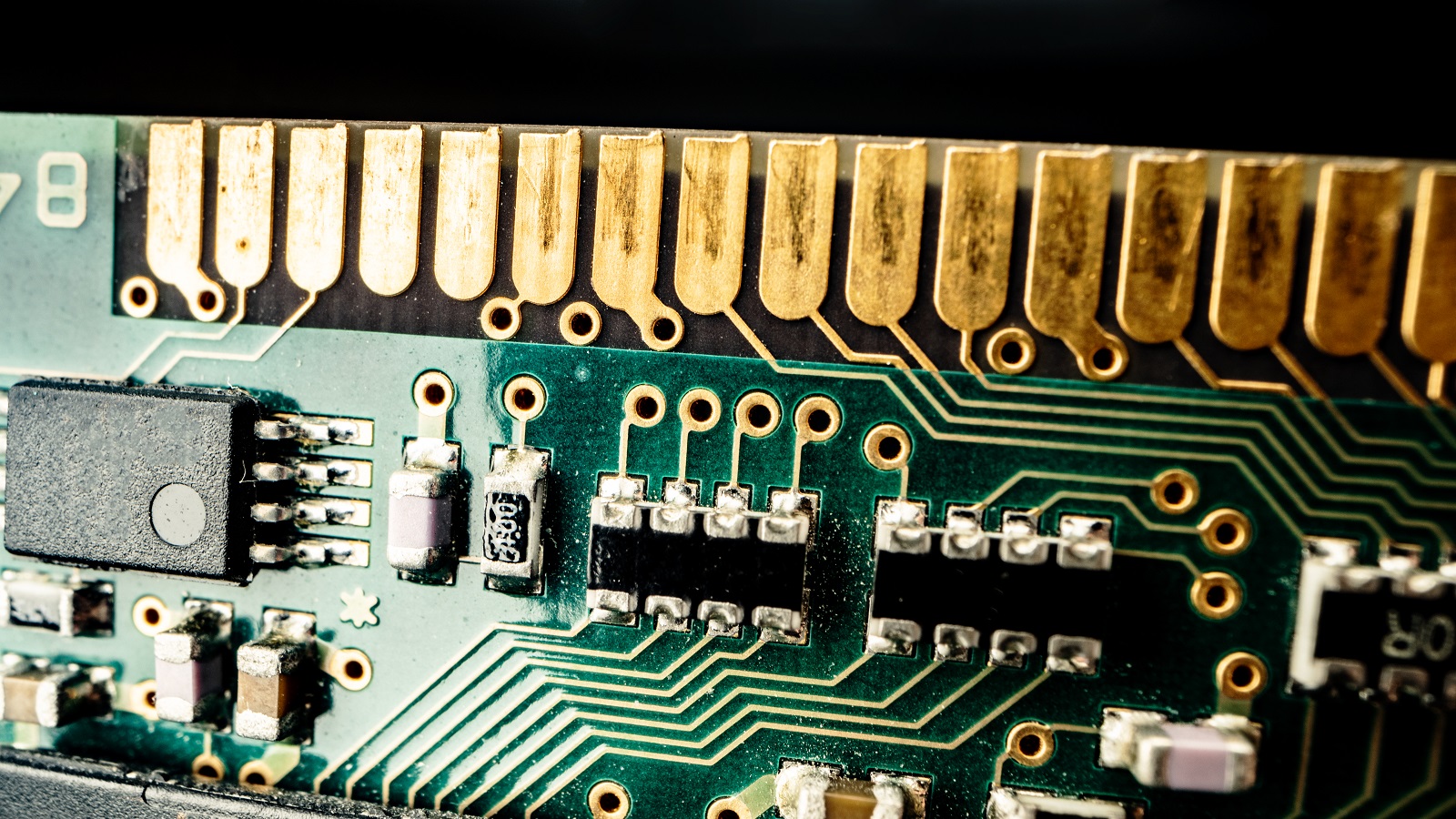

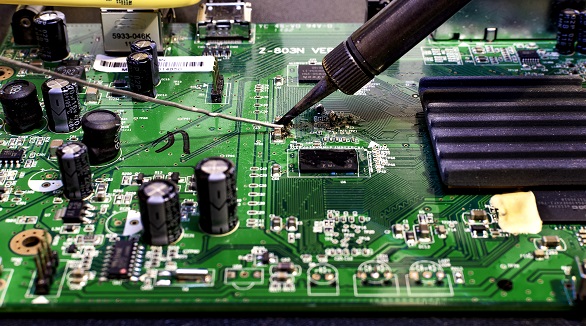

Other advantages of SMD resistors are those related to their workability with automated manufacturing. The possibility of using pick-and-place machines during the assembly of these resistors onto PCBs lowers the labor costs and increases the speed of manufactured output. Automation enhances both the speed and the precision of production and diminishes errors, thus allowing for more reliability in the finished electronic products. This efficiency extends to cost savings as well; the less complex setup and reduction in manual assembly translate to lower production costs, making SMD technology a cost-effective choice for large-scale manufacturing.

Improved Thermal Management and Reliability

The physical properties of SMD resistors contribute to improved thermal management. Due to the nature of these resistors being directly mounted to the PCBs, heat generated by them could easily be dissipated through the board itself, which acts mostly as a heat sink. This capability is vital in sustaining performance and longevity in electronics, especially when considering packed designs where heat could be an issue. It also makes them inherently more resistant to mechanical stress and vibration due to their construction without leads, enhancing reliability and thereby extending their use into other selected fields like automotive and aerospace.

Weight Reduction and Implications for Mobility

As the demand for more mobility and wearable technologies continues to rise, this reduction in weight brought about by SMD resistors is a welcome relief. They also contribute to the total weight efficiency of a device and, therefore, are ideal for weight-critical applications such as drones, medical devices, and portable electronics. With this reduction in weight, there is no compromise on either performance or durability, and hence the solution keeps pace with current design philosophies that border on portability, without necessarily touching functionality.

Lower Inductance and RF Applications

Geometrical construction provides SMD resistors with low intrinsic inductance, which becomes very useful in RF applications and high-speed data lines. The low inductive nature ensures that these resistors would introduce minimal phase shifts and signal distortion, ensuring signal integrity even at high frequencies. This is an essential feature in telecommunications and data networking equipment, where the signal fidelity has to be retained for optimum performance.

Conclusion

In summary, this leads back to the revolutionary benefit imposed by the SMD resistor, which has been driven into ubiquity in today's electronics. Indeed, with a boost toward miniaturization, high-frequency performance, and manufacturing efficiency, their place within designs has been secured for both contemporary and future applications. As technology strides in tandem with advancement, the adoption of SMD technology would increase proportionately to satisfy increasing demands for smaller, more intelligent, and more capable gadgets. The movement to SMD components reflects larger themes within the industry at large: a march toward automation, high performance, and greater integration, so that they render key drivers in advancing the frontiers of what is achievable in electronic design and functionality.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

SMT has transformed electronics manufacturing by enabling automation and miniaturization, leading to more efficient assembly processes and the production of high-quality, compact electronic devices.

SMD soldering mounts small components on the PCB surface for compact, automated designs but has high setup costs and repair challenges. DIP soldering uses through-hole components for robust, easily repairable, lower-volume applications.

Compared to THT, SMT offers better miniaturization and weight reduction in any electronic application. With the use of BGA packages, high-assembly density, reliability, and improved performance are achieved; on the other hand, this requires a rework and inspection that is not really common. PCBX specializes in the area of advanced SMT and BGA assembly to help drive modern requirements of compact electronic devices.