What Are the Factors that Affect Wave Soldering?

Wave soldering quality hinges on several factors: consistent solder contact, precise heat management, optimal separation speed, and controlling solder surface tension. Key considerations include deoxidizing surfaces for effective wetting, strategic lead/pad design, and correct component orientation. Mastering these variables enhances PCB assembly reliability.

Any form of soldering must put sufficient solder everywhere it's needed – and none where it can cause problems (shorts, balls, spikes, and the like), which is the bare minimum, high quality in a PCB assembly. The ideal to be achieved in wave soldering is 360° solder connections without any gaps between the leads and pads, and for plated through-holes, complete vertical fill. While standards may allow less than perfect, understanding and working with the forces controlling solder flow makes achieving 100% perfection more likely.

Key Forces in Wave Soldering

Consistent and Complete Touch

In other words, making sure that the solder wave, PCB, and component leads are all in steady, complete touch is a fundamental necessity. Any disruption will result in incomplete soldering, which leads to flaws.

Heat

Heat plays multiple roles in wave soldering:

- Pre-Wave Heating: Before the PCB gets into the solder wave, enough heat must be applied to drive off the solvents and activate the flux for deoxidizing surfaces. This is done by heaters under the conveyor.

- Solder Temperature: On single-sided boards, the solder temperature must be sufficiently high to allow the solder not to freeze before the board has separated from the wave. For assemblies with plated through-holes, the temperature at the top side of the board must be above the melting point of the solder to ensure complete vertical fill.

- Previously, preheaters were located under the conveyor, with the solder bath providing supplementary heat. For more complex assemblies, topside heaters become necessary to provide uniform heat distribution that prevents excessive solder temperatures, which can be problematic due to dross formation, degradation of the machine's parts, and PCB damage.

Separation Speed

The more slowly the separation from the solder wave, the more excess solder will be able to drain back into the bath, thus minimizing the risk of defects such as bridges and spikes.

Solder Surface Tension

Surface tension is very important for the control of solder:

Snapback: Provided that surface tension is at the correct optimum value, solder is capable of snapback. Avoiding excessive solder deposits and bridges, oxidation will reduce surface tension and increase the likelihood of excess solder and hence defects.

Interatomic Attraction

The leads must be effectively deoxidized:

- Wetting: Solder will not adhere to an oxidized surface. Pure metals bond well to each other, allowing solder to wet well and form a good intermetallic bond. Solder is repelled by oxidized metals because there exists no interatomic attraction.

- Lifted Components: Interatomic attraction holds the component steady on the surface of the PCB and prevents parts from lifting. Solderability issues should be viewed with sufficient seriousness so there would be no reason to fall back on ineffective solutions by adding weights or some other mechanical fix.

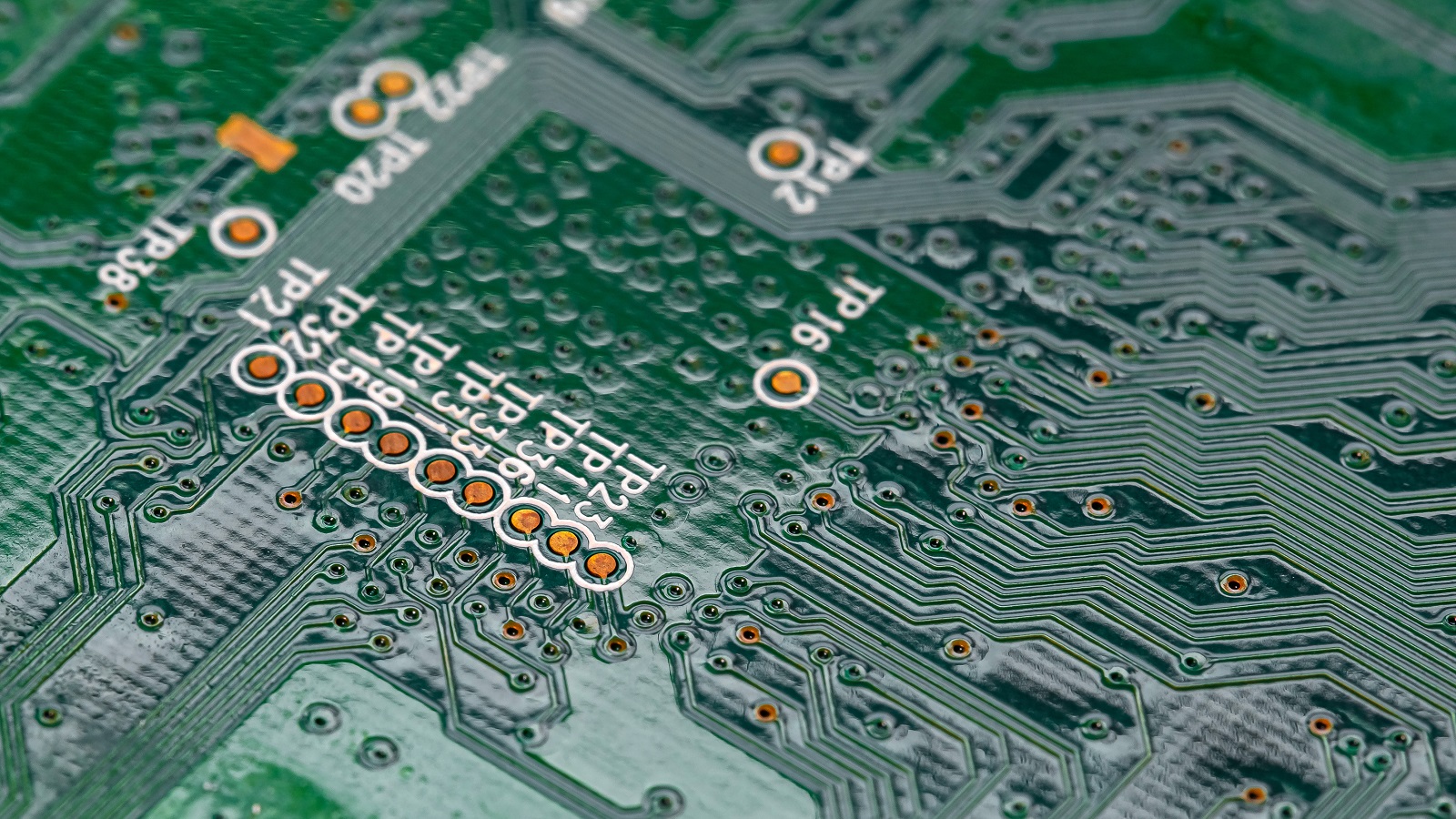

Area of Metal Surfaces Exiting the Wave

Solder flow affected by lead and pad configuration

Lead Position: Dual inline packages should be positioned at the right angle to the wave. Sequential lead exit allows flow, minimizing the chance of bridge.

Solder Thieves: Non-functional pads are added on the training edge of pads to encourage solder to take extra solder away, reducing the chance of bridge.

Precautions in Wave Solder Analysis

An understanding of these forces shall enable the engineer to optimize wave soldering equipment and process configuration. Some actionable insights are as follows:

Pre-Wave Heating: Employ top and bottom preheaters, with adjustments in heat input based on thermal mass.

Conveyor Speed: Optimize the conveyor speed for proper soldering time without overheating.

Surface Tension Management: The solder surfaces are checked regularly against oxidation, and fresh flux is applied to maintain the required high surface tension.

Component Orientation: Regard the orientation of components concerning the solder wave to prevent bridging and other defects.

Mastering these variables can help much toward improving the reliability and quality of wave-soldered assemblies.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.