What is Chip on Board?

COB technology mounts chips directly on PCBs without packaging, reducing size and weight while improving performance and thermal management, ideal for compact devices like wearables and LEDs.

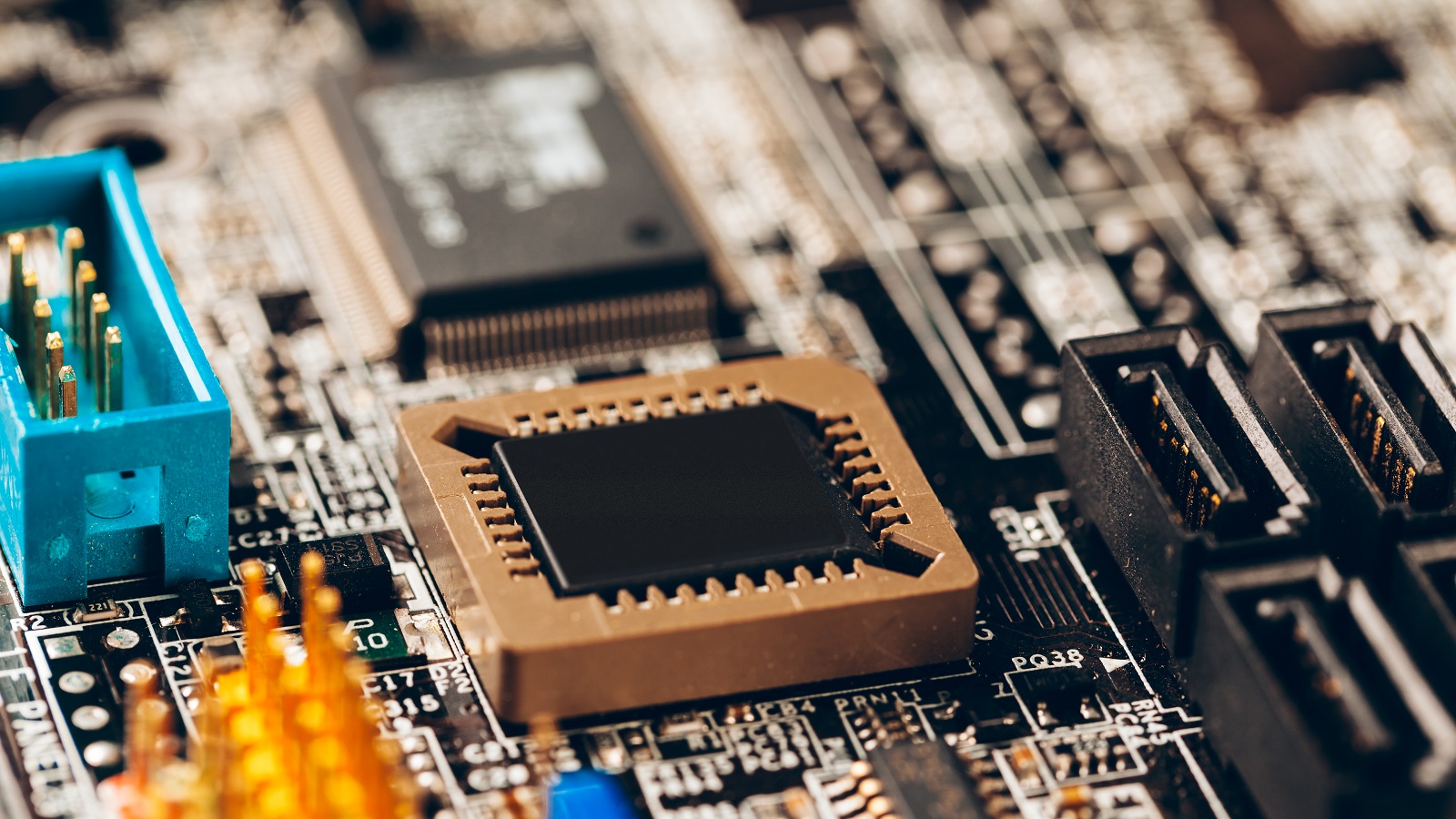

As the environment of electronics is getting changed rapidly, there is an increasing demand for smaller, efficient, and high-performance devices. COB, or Chip on Board, is one of the highly advanced techniques for mounting bare ICs directly onto a PCB. It meets these demands for space and performance by minimizing space usage and enhancing performance. This process eliminates any packaging with ceramics or plastics and offers a streamlined approach to several electronic assemblies.

What is Chip on Board Technology?

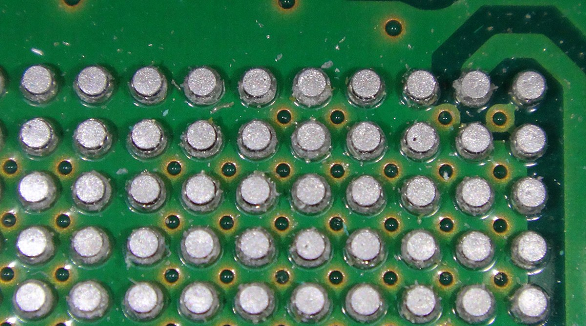

Chip on Board Technology refers to a method of mounting a bare semiconductor chip directly on a PCB. The chips are not individually packaged but are directly attached to the board. This allows for an increase in the component densities of the board and a reduction in packaging materials. These chips are then connected to the board through the use of very small solder bumps or adhesives that keep them in the right position and ensure reliability within their connections. The absence of conventional packaging further reduces the size and weight of the electronic assembly; hence, COB finds ideal applications where space is in shortage: wearable devices, LED lighting, and mobile advanced technology.

Advantages of Chip on Board Technology

Compact Size and Weight Reduction

By eliminating the large, conventional package, COB reduces the size and weight of the electronic components. This is a factor in consumer electronics, where the trend is toward lighter, more portable designs.

Better Electrical Performance

The chip is directly bonded to the PCB to reduce the length of the electrical path. This reduces the interference of the signal or its loss. The resulting direct connection enhances the signal integrity, hence allowing high speeds and a reliable operation.

Better Thermal Management

Chips without an insulating plastic or ceramic package dissipate the heat much more effectively by being directly mounted onto the PCBs. This effective thermal management is extremely important for high-performance chips to have stability and longevity, especially in applications where generation of heat could otherwise lead to device failure.

Cost-Effective Production

COB reduces the material costs associated with traditional packaging solutions and often can simplify the assembly processes to have lower overall production costs.

How are Chip-on-Board Assemblies Manufactured?

Manufacturing a COB assembly requires several precise stages:

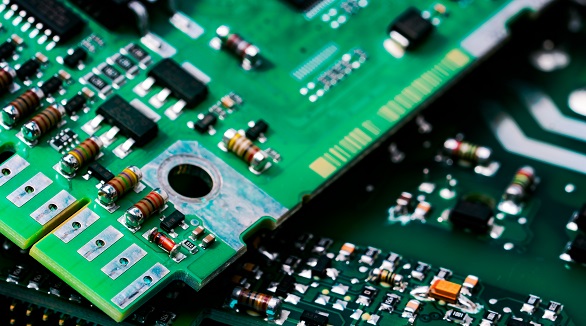

Substrate Preparation

The initial preparation of the PCB includes cleaning, then coating it with a thin adhesive or conductive layer where chips will be mounted. The preparation will offer a quality surface for mounting the chips.

Die Attach

In this regard, bare semiconductor dice are placed with a great amount of accuracy onto the prepared areas of the board using advanced pick-and-place machines. Attachment and electrical interconnection are reliably done by either adhesives or solder materials.

Bonding

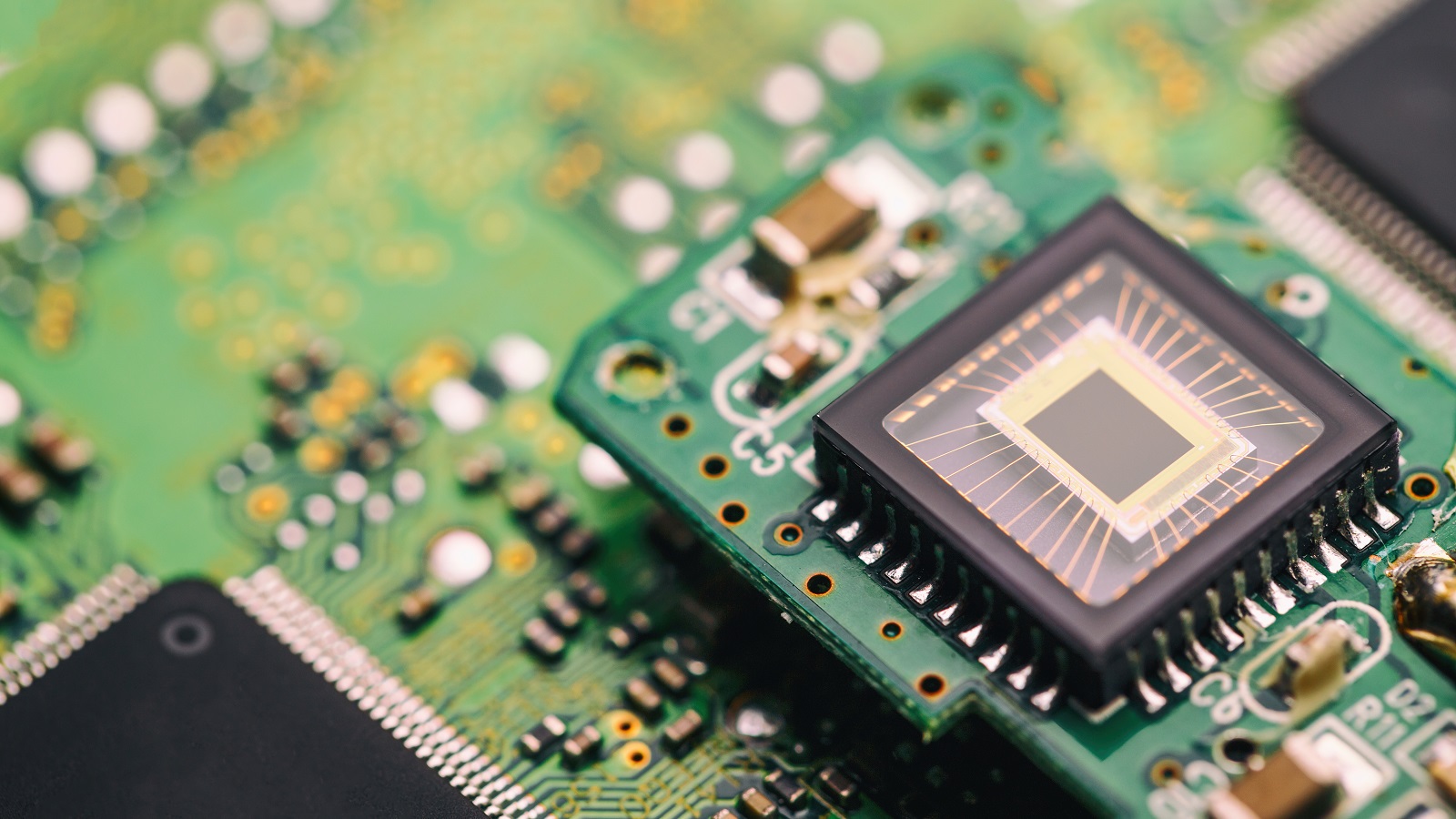

Next, chips are bonded to the PCB through solder bumps, which offer a direct path from the chip's contacts to the board's copper traces for electrical signals. In this way, efficiency in signal transmission is achieved along with reliability.

Wire Bonding

If there is a need for more connections, then fine wire bonding is used to connect the chip's pads to the PCB. This allows for strong electrical communication and thus finds its usage quite commonly in the case of more complex chips.

Encapsulation

The encapsulant material-usually some sort of epoxy-is applied to protect the fragile wire bonds and chips, protecting them from environmental damage while providing mechanical stability.

Testing

The testing includes temperature cycling, electrical performance tests, and a visual check to ensure the assembly can pass all reliability and functionality standards.

Final Assembly

Once the COB assembly integrity has been functionally validated through testing, it is ready for final assembly into consumer end products such as LED displays or smartphones.

Advanced Techniques and Applications

Another advanced technique explored in PCBasic is flip-chip technology, wherein the chip is mounted face down. It gives even higher connection reliability and electrical performance because of the solder balls pre-applied at wafer level. More and more protective processes are used with it-like glob-top or dam/fill coating-for its durability and longevity.

Application Insights: COB in LED Lights

In LED technology, COB has carved a niche for itself as a worthy competitor to conventional methods. COB LEDs embed multiple diodes directly onto the substrate to achieve better lumen density and enhanced light uniformity. Employing multiple diodes per chip often allows brighter light outputs and usually simplifies circuit design for improved thermal performance.

Advantages of COB LEDs

Increased Compactness: With the better utilization of space, lighting fixtures can also be smaller in size without losing quality in light.

Uniform Light Distribution: As the technology emits more uniform light output, there are minimal hotspots within the illumination, allowing it to look much more aesthetically pleasing.

Efficiency: With fewer components required, it leads to a clean and streamlined product design.

Challenges and Considerations in COB Technology

There are intrinsic hurdles in implementing COB technology. The need for special equipment for wire bonding and encapsulation tools will increase upfront expenses. Challenges such as thermal expansion mismatch and substrate connect reliability have to be duly addressed in order to keep product quality and performance intact.

Conclusion

Chip-On-Board technology is one major step toward miniaturization and efficiency of electronic assemblies. COB offers better space saving, higher electrical performance, and improved thermal management by directly mounting chips onto the PCBs without traditional packaging. This technology is irreplaceable for advanced applications needing compact, high-density, and high-performance solutions. While electronic devices continue to miniaturize into smarter devices, COB will remain one of the main techniques in extending the frontiers of possibilities within electronics manufacturing and, consequently, driving innovation across industries-from consumer electronics to advanced lighting systems.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

IC packaging is essential in electronics for protecting components, providing electrical connections, and managing heat. This tutorial explores its complexities, including its importance, various types like SMD, QFP, and BGA, and considerations for choosing the right package for specific applications. Proper IC packaging enhances PCB performance and reliability.

Printed Circuit Board Assembly (PCBA) employs Through-Hole Technology (THT) and Surface Mount Technology (SMT). THT offers robust mechanical bonds, ideal for high-stress applications, whereas SMT supports efficient, high-density assemblies. Each method has unique advantages and limitations, impacting cost, manufacturing efficiency, and component compatibility. Understanding these differences is key for optimal PCB design.

In the late 1980s, when electronics began to shrink, BGA packaging was developed to integrate more connections within a given area. Today, BGA is widely used with high-connection chips—processors being a good example. BGA uses solder balls at the bottom of the chip to connect it to the circuit board. It provides high density along with good heat dissipation and fast signal transmission, one of the main reasons it is ideal for modern electronics. However, it requires precise techniques of soldering in BGA manufacturing.