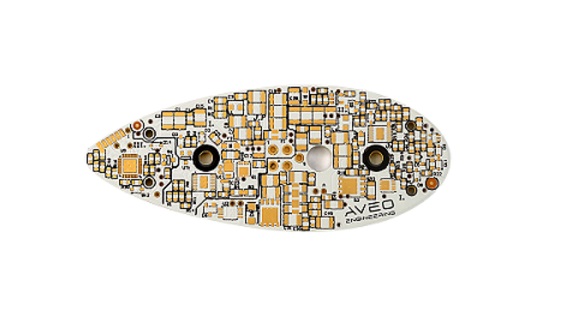

What is a Rogers PCB?

Rogers PCBs offer superior dielectric properties, thermal stability, and design flexibility for high-frequency applications in telecom, aerospace, automotive, and more.

Rogers PCBs are specialized printed circuit boards made from materials developed by the Rogers Corporation, which is a global leader in engineered materials for high-performance electronics. Unlike the normal FR-4 PCBs normally made from glass fiber and epoxy resin, Rogers PCBs employ substrates filled with ceramic. In this way, superior electrical properties are possible to realize, hence making them suitable for high-speed and high-frequency applications.

Features

Superior Dielectric Properties: One of the key qualities that distinguish Rogers PCBs is a steady dielectric constant, which is critical for signal integrity at high frequencies. They have minimal dielectric losses, which reduces signal attenuation and ensures good sound performance.

Temperature Stability: Rogers materials are highly thermally stable; the thermal expansion coefficient of the dielectric constant is very close to that of copper. The closeness in coefficients guarantees good performance with variations in temperatures and adds to the durability of the electronic device.

Low Water Absorption: These materials have low water absorption and, hence, can be applied under humid conditions, too. This feature also helps a lot in keeping the performance of electronics stable in conditions of variable environmental parameters.

Thermisches Management: In this aspect, the Rogers PCBs support higher thermal managing properties. High thermal conductivity with low coefficients of thermal expansion effectively dissipates the generated heat-a highly desirable feature in high-power applications.

Dimensionelle Stability: These PCBs possess very good dimensional stability that allows accuracy for high-frequency and high-density circuit designs, found useful in a lot of applications that involve consistent performance and reliability.

Design Flexibility and Miniaturization: With the Rogers material, constructively, it becomes possible to have more complex and denser circuit design; hence, the support of miniaturization in advanced aspects of electronic components.

Applications

Due to its special characteristics, there are extensive applications for Rogers PCBs related to high-performance and reliability issues. Their versatility and capability extend their usage into many industries:

Telecommunication: From RF communication systems down to antennas, microwave towers, and more, Rogers PCBs see wide usage where telecommunications involve very high-frequency signal handling with minimal loss.

Aerospace and Defense: Materials by Rogers find extensive application in aerospace and defense due to their stability and reliability.They are used in radar systems, avionics, and communication equipment since the performance of these materials has to be in accordance with strict regulatory standards.

Automotive: The Rogers PCBs have a huge demand in the automotive industry due to the use of rising integrated technology, such as using radar systems to avoid collision, among other autonomous driving systems, which require signal integrity and reliability due to their dynamic nature.

Medical Devices: Medical devices require the ultimate in precision and dependability. When applications call for high degrees of signal transmission accuracy in the generation of proper results, such as MRI machines or diagnostic equipment, Rogers PCBs are there to get the job done.

Consumer Electronics: High-end consumer items requiring rapid data processing with reliable signal performance, like high-speed routers or smart devices, rely on Rogers PCBs for their functions.

Benefits

Rogers Corporation manufactures a wide variety of materials engineered for high-frequency, high-performance applications. Besides, representative series include RO4000, RO3000, and RT/duroid, each designed for particular applications. These materials have the following characteristics:

High-Frequency Performance: They maintain stable dielectric properties, as needed for RF, microwave, and millimeter-wave applications, hence the ability of the device to operate at higher frequencies with maximum functionality.

Thermal Management: Rogers materials provide excellent thermal conductivity and stability to allow for proper heat dissipation in circuit boards.

Signal Integrity: From excellent dimensional stability down to smooth copper surfaces, these materials are making great improvements in the speed and integrity of signals through PCB traces.

Design Flexibility: A wide variety of material specifications including various dielectric constants and loss tangents gives designers the flexibility to meet a wide range of application requirements.

Rogers PCBs represent state-of-the-art electronics manufacturing products, ensuring unrivaled performance, outstanding reliability, and versatility. For the companies to which technology knows no bounds, a starting point to innovation and excellence is offered by the different Rogers materials. Here at PCBX, we value these highly important materials and strive to provide solutions that will fully exploit their potential to the maximum extent possible.

By integrating Rogers PCBs into high-frequency applications, designers and engineers can achieve optimal performance, signal integrity, and miniaturization. As the technology landscape continues to evolve, Rogers PCB will remain a cornerstone of electronic design, enabling advancements that define the future of communication, defense, automotive, and healthcare.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Heavy copper PCBs enhance current capacity and thermal performance, essential for high-power applications in military, automotive, and energy sectors, offering strength and heat dissipation.

Most electronic circuits are mounted on PCBs, or Printed Circuit Boards, which provide mechanical support and electrical interconnection of electronic components. There are, however, special applications that involve the use of single and double-sided PCBs, multi-layer PCBs, or even rigid and flexible PCBs with aluminum backing, targeting medical, industrial, auto, and aerospace industries. They may use materials such as fiberglass, epoxy, aluminum, and others.

Aluminum PCBs are widely used electronic boards with comparatively better heat dissipation properties. The aluminum core cools down the components of the product, thereby improving its performance. These are eco-friendly, light, and strong PCBs and hence appropriate to be used in audio equipment, power supplies, and lighting products such as LED lighting.