What is the difference between PCB and PCBA?

One is a bare circuitry board, and another has all the components and is functional: PCB stands for Printed Circuit Board, and PCBA stands for Printed Circuit Board Assembly. PCB acts like a base, and components are assembled on it at a later stage through various methods in PCBA, such as SMT and Thru-Hole Technology.

PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) are crucial in the electronics industry. Although these two are often used interchangeably, they represent different concepts. The primary difference is that the PCB denotes a bare circuitry board; however, the PCBA refers to a board that incorporates all the essential electronic components required to operate effectively. PCB is not yet functional due to the absence of required components, while PCBA is a fully assembled and operational board. PCB and PCBA are two stages of the same manufacturing process, where PCBA is constructed upon an existing PCB.

In this guide, we will delve into the definitions of PCB and PCBA and explore the differences between these two terms.

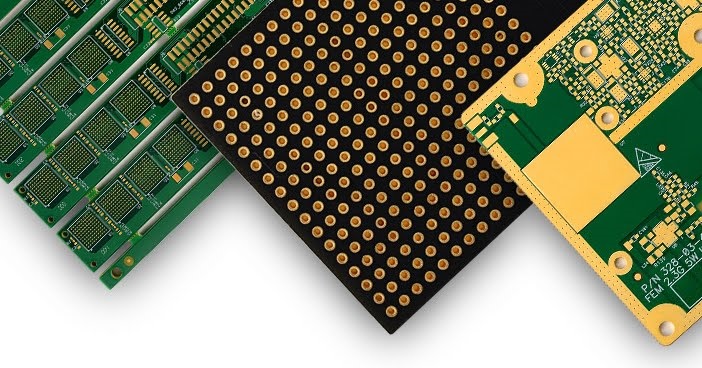

What is PCB?

PCB (Printed Circuit Board) is the backbone of contemporary electronic devices, providing mechanical support and electrical connections for various components. These boards are typically fabricated from laminate materials such as fiberglass or composite epoxy, and they feature conductive pathways that interlink different sections, meticulously printed or etched onto the PCB following a predetermined design.

Types of PCB

PCB comes in several variations, including:

Single-layer PCB: The most basic type, featuring a single layer of conductive material, with a solder mask. The components on the PCB are marked with a silkscreen.

Double-layer PCB: With conductive material on both the top and bottom layers, offering greater flexibility and reduced size compared to single-layer PCB.

Multi-layer PCB: Comprising more than two conductive layers, this kind of board is designed for more intricate applications.

Additional types of PCB include flexible PCB, rigid PCB, and flex-rigid PCB, each serving specific purposes and applications.

PCB Materials

The substrate material for PCB is typically fiberglass, composite epoxy, or another laminate material. Copper is commonly used as the conductive material on one or both sides of the board. The printed circuits are either plated or etched onto the substrate per the design specifications and are often coated with tin-lead to prevent oxidation. Contact fingers along the board's outer edges are coated with tin-lead or alternative materials such as nickel and gold to enhance conductivity.

Applications

PCB serves diverse electronic devices and sectors, from consumer electronics to industrial machinery and medical equipment. Notable examples include:

Computers

Cell phones

TVs

Radios

Printers

Calculators

Appliances

Lighting systems

Medical imaging systems

Pacemakers

Engine management systems

Industrial controls

Telecom towers

Data storage equipment

Satellite systems

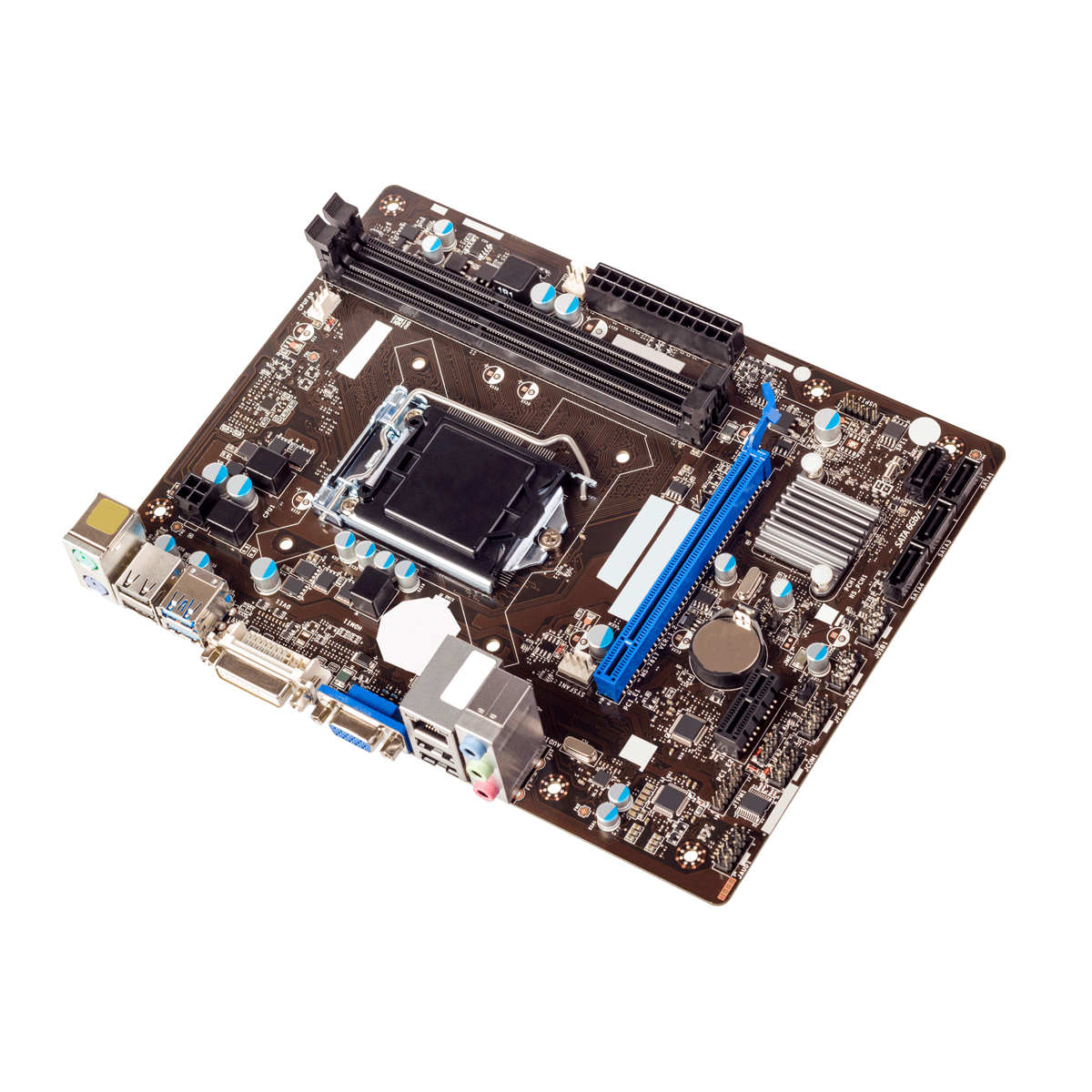

The Definition of PCBA

PCB refers to a blank circuit board, while PCBA (Printed Circuit Board Assembly) is a fully assembled board containing all the electronic components necessary to function as intended. PCBA can also denote the process of assembling these components onto the PCB.

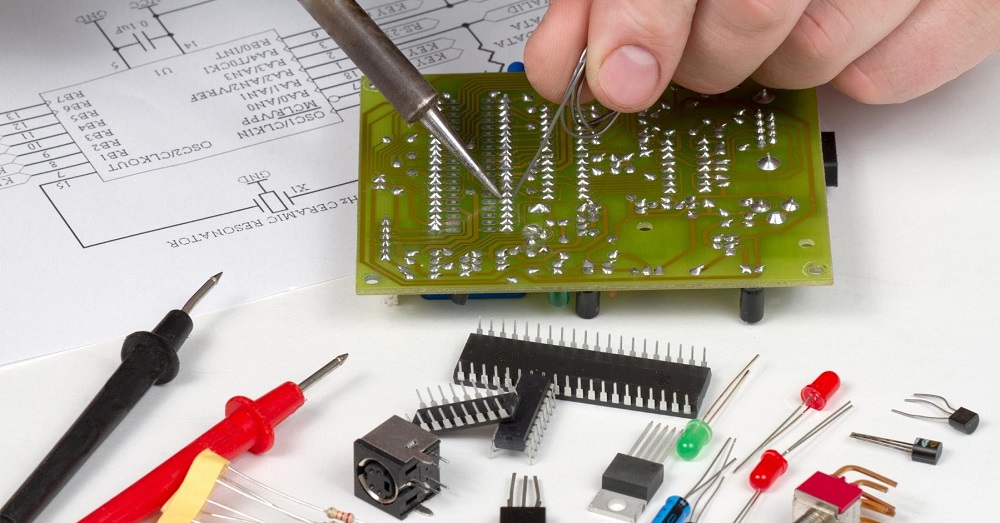

Methods of PCB Assembly

Companies specializing in PCB assembly generally employ two main methods:

1. Surface-Mount Technology (SMT)

Surface-Mount Technology (SMT) involves mounting electronic components directly onto the surface of the PCB, which is highly automated and allows for higher connection densities, enabling manufacturers to incorporate complex circuitry into compact components. The basic steps of SMT for PCBA are:

Preparing the PCB: Solder paste is initially applied to designated areas on the board.

Placing the Components: Components are then positioned on the board, typically using a pick-and-place machine.

Reflow Soldering: The assembled board is heated in a reflow oven until the solder paste melts and forms solder joints.

Inspection: Inspections are performed throughout the SMT process, including pre-placement, pre-reflow, and post-reflow stages.

2. Thru-Hole Technology

Thru-Hole Technology is an assembly process where holes are drilled into PCB to allow the attachment of electronic components known as leads. Although it is an older technology than SMT, Thru-Hole Technology provides stronger connections between the board and components, resulting in more durable and reliable assemblies. The steps involved in the Thru-Hole process are:

Drilling the Holes: Holes are drilled into the PCB and sized appropriately for the component leads.

Placing the Leads: The leads are then inserted into the drilled holes.

Soldering: Soldering is conducted to secure the components firmly in place.

Inspection: Continuous inspections ensure that the PCBA functions as expected.

Both SMT and Thru-Hole methods have their respective advantages and are chosen based on the specific requirements of the electronic assembly.

How do PCBA and PCB Relate to Each Other?

PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) are two different phases of the same manufacturing process. PCBA is a completely constructed circuit board that has all the parts required for it to function in a particular application, whereas PCB is a blank circuit board that is devoid of any electronic components. PCBA is prepared for installation in an electronic device, while PCB is not operational.

The production of PCB is simpler than PCBA because of the complexity of attaching numerous components and the processes involved. Consequently, PCBA's production is more expensive than PCB's. Regardless, both procedures are essential; one cannot create PCBA without first making PCB. PCB manufacturing is the first process, followed by PCBA assembly, which adds to the blank board.

Additionally, PCB and PCBA differ in their packaging methods. PCB is usually vacuum-packaged, while PCBA requires compartmental or anti-static packaging to protect the assembled components.

Our PCBA Services

PCBX specializes in comprehensive PCB assembly services, including board-level and complete box-build assembly. Our expertise covers Surface-Mount Technology (SMT) and Thru-Hole Technology, utilizing fully automated processes and precise hand assembly techniques.

Collaborating with PCBX, you will benefit from our extensive experience, prompt service, and commitment to product excellence. To discover how our PCB assembly services help you, contact us online or request a free, no-obligation quote today.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Dive into our PCB glossary to master the key terms and definitions essential for efficient design and production, ensuring your projects run smoothly and effectively.

Most electronic circuits are mounted on PCBs, or Printed Circuit Boards, which provide mechanical support and electrical interconnection of electronic components. There are, however, special applications that involve the use of single and double-sided PCBs, multi-layer PCBs, or even rigid and flexible PCBs with aluminum backing, targeting medical, industrial, auto, and aerospace industries. They may use materials such as fiberglass, epoxy, aluminum, and others.

The article explains the current situation of Printed Circuit Boards and future development based on efficient production helped by advanced software and manufacturing processes. Future technological developments are in store for 3D Printed Electronics, flexible PCBs, eco-friendly biodegradable PCBs, and board cameras. It elaborates on other powerful automation tools that are going to make the entire PCB design process efficient in the near future. All of them will further improve and develop with the technological advances in PCBs, keeping up with the ever-increasing industry and consumer demands.