Why do We Need PCB?

PCBs are essential for organizing information and power flow in electronic devices, benefiting from flexibility, durability, safety, efficiency, and heat management.

PCB (Printed circuit board) is the inconspicuous hero behind most daily electronic devices from smartphones and laptops to televisions and automobiles, PCBs silently organize the flow of information and power that makes these devices function.

Delving into the World of PCBs

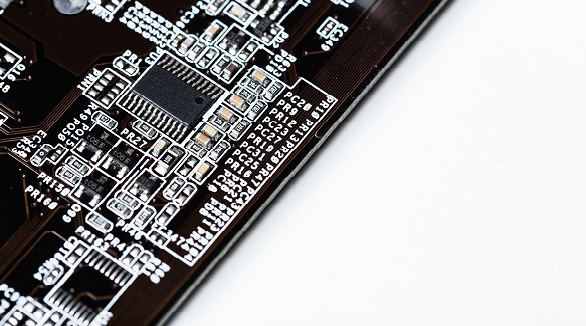

PCBs are essentially laminated electronic boards with etched metal channels. These routes, also known as traces, act as a network for electrical impulses to pass between various components on the board. PCBs are available in a range of forms and sizes to meet the needs of certain applications. Some PCBs include drilled holes for component leads, while others use surface-mount technology (SMT), in which components are soldered directly to the board's surface. SMT progressively surpasses through-hole technology because of its advantages in terms of space savings and increased production efficiency.

A Spectrum of PCB Options

The diverse type of PCBs could suit various project needs. There's a perfect PCB for every project from flexible PCBs that can bend without breaking to rigid ones ideal for harder applications. Single-layer PCBs, ideal for simpler devices, coexist with complex multi-layered PCBs capable of accommodating intricate functionalities. The material composition of PCBs also varies, with FR4 glass epoxy laminate being a popular choice. PCBX specializing in PCB assembly provide services for mounting electronic components onto the board, often catering to specific areas like embedded systems or wireless technology.

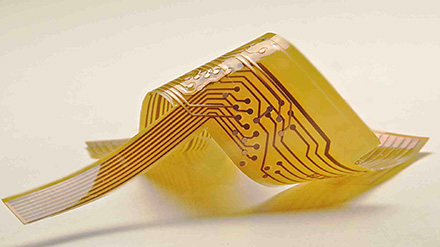

The Power of Flexibility: Flexible PCBs

Flexible PCBs, made of silicone or polyimide, have the unique ability to bend without being damaged. These boards come in two primary configurations: rigid-flex PCBs, combining rigid and flexible sections, and flexible PCBs that can be folded in half.

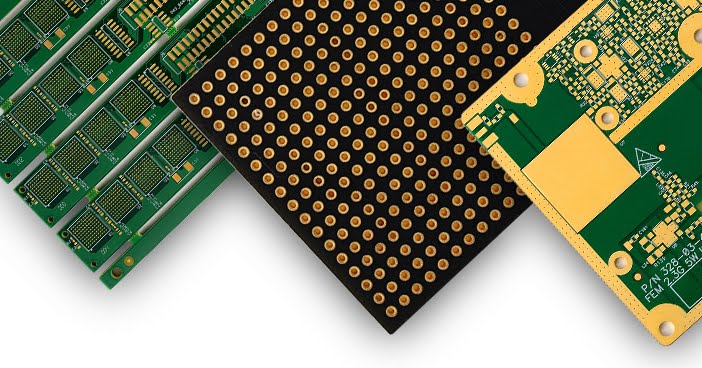

Layered Complexity: Single-layer vs, Multi-layer PCBs

PCBs exist in various thicknesses, with single-layered boards being the simplest form and multi-layered boards offering increased complexity. As the number of layers increases, so does the board's functionality. While single-layered PCBs are suitable for simpler devices, multi-layered PCBs are the backbone of more sophisticated electronics.

The Ubiquitous Presence of PCBs

It's nearly impossible to imagine of an electronic device that doesn't rely on at least one PCB. From smartphones and computers to tablets, televisions, and even automobiles, PCBs are omnipresent. Their primary function lies in facilitating communication between various components within a device. Imagine your phone – the PCB seamlessly connects the display, buttons, and internal circuits, enabling them to function in unison. Without this crucial component, your phone would be useless. Additionally, PCBs serve as protective barries for these fragile components. By encasing them within the board and employing metal layers, PCBs form a Faraday cage that safeguards components from external disturbances like electromagnetic radiation.

The Advantages of PCBs

The benefits of using PCBs are numerous. Firstly, PCBs make it possible to design smaller, more portable devices. The small design of PCB traces allows for significant size reduction compared to using individual wires. This space-saving advantage also simplifies circuit assembly and trace routing. Secondly, PCBs are renowned for their durability because they can withstand exposure to heat, moisture, and even physical impact remarkably well, which makes them ideal for use in challenging environments, such as under the hood of a car where they encounter oil, water, and other harsh conditions. Withstanding these elements is essential for ensuring the proper functioning of critical systems like braking systems. Thirdly, PCBs prioritize safety. The encapsulated nature of PCB traces minimizes the risk of accidental contact with live circuits, significantly reducing electric shock. Fourthly, PCBs promote efficiency and cost-effectiveness. By minimizing the number of components required, they contribute to lower production costs for both manufacturers and consumers. Finally, PCBs are relatively easy to repair and recycle. Replacing a faulty component on a PCB is often simpler than troubleshooting a complex wired circuit. Furthermore, PCBs can be recycled at the end of their lifespan without causing negative environmental consequences.

Maintaining the Cool: Thermal Considerations

Another important function of PCBs is heat dissipation. Every component in a circuit produces heat, which can cause device failure if left uncontrolled. The metal layers on a PCB operate as heat sinks, taking heat away from heat-generating components and allowing it to dissipate. This heat management keeps your device from overheating and ensures that it runs smoothly for an extended duration. Overheating is a common cause of electronic failure, and PCBs play an important role in reducing this risk by keeping components cool. However, it is vital to remember that the metal layers used for heat dissipation might also function as insulators, thereby impeding effective heat transport away from the device. Thermal vias, tiny conductive pathways connecting multiple PCB layers, can help address this challenge, but their implementation isn't always feasible.

In conclusion, printed circuit boards are the unsung heroes of the electronics industry. Their vital purpose is to link components, provide communication, and ensure safety.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Multilayer PCBs, essential for advanced electronics, offer compact size, lightweight, and high performance, making them ideal for various applications despite higher costs and complexity.

Most electronic circuits are mounted on PCBs, or Printed Circuit Boards, which provide mechanical support and electrical interconnection of electronic components. There are, however, special applications that involve the use of single and double-sided PCBs, multi-layer PCBs, or even rigid and flexible PCBs with aluminum backing, targeting medical, industrial, auto, and aerospace industries. They may use materials such as fiberglass, epoxy, aluminum, and others.

The article explains the current situation of Printed Circuit Boards and future development based on efficient production helped by advanced software and manufacturing processes. Future technological developments are in store for 3D Printed Electronics, flexible PCBs, eco-friendly biodegradable PCBs, and board cameras. It elaborates on other powerful automation tools that are going to make the entire PCB design process efficient in the near future. All of them will further improve and develop with the technological advances in PCBs, keeping up with the ever-increasing industry and consumer demands.