Why PCBA One-Stop Service Become popular?

Customers prefer one-stop PCBA service not only because of price transparency; it can save time and reduce labor costs with efficiency and professionalism in procurement and production.

Previously, customers usually purchase PCB circuit boards and electronic components separately. However, an increasing number of clients are asking their suppliers for one-stop PCBA (Printed Circuit Board Assembly) services. Here are the reasons why do integrated PCB and component procurement services are gaining popularity:

First: online component salesand prices tend to be transparent

Nowadays, component sales channels are highly networked, and pricing has become more transparent. If one goes online, they will find a wide range of materials for sale as well as their costs, production information or the present stocks available. When a company decides to purchase components on its own, it must have personnel knowledgeable about materials to verify the authenticity of the component supplier and determine shipping times. But in many cases, this means spending extra to complete the same task.

Second: rising labor costs and uncertainty influencing factors

Given the current volatile economic climate, many companies are grappling with decreasing orders. Amidst stagnant or declining orders, reducing labor costs becomes more challenging. One-stop PCBA service includes a comprehensive budget with controllable pricing could eliminate the additional costs and minimize the uncertainties.

Third: Professional team, experienced and efficient

Generally the solution providers may lack in-depth knowledge about the latest price trends for PCB circuit boards, components, and new SMT (Surface-Mount Technology) advancements because they are not directly involved in the production process. While PCBA manufacturers are more experienced in handling daily backend processes and their engineers are well-versed in industry-specific requirements, including the appropriate type of board and solder paste to use. Moreover, PCBA vendors typically serve multiple clients and thus have higher demands for parts procurement, which enables them to access better terminal channels, securing more products at lower prices while ensuring quality. Terminal distributors are keen to maintain their primary customers, so PCBA manufacturers could get better prices and other conditions compared to companies that might not meet the minimum quote requirements from other suppliers.

Choose PCBX for Reliable One-Stop PCBA Solutions

If you are in search of a dependable one-stop PCB assembly service provider, look no further than PCBX. Contact us now for a free PCBA quote!

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

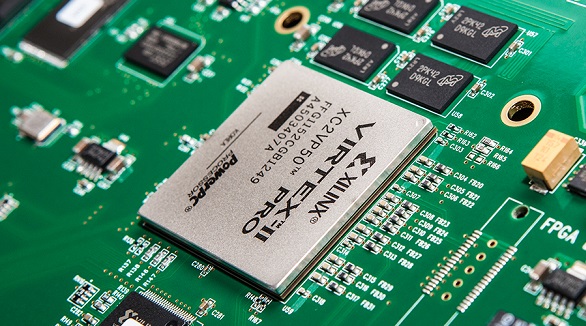

Compared to THT, SMT offers better miniaturization and weight reduction in any electronic application. With the use of BGA packages, high-assembly density, reliability, and improved performance are achieved; on the other hand, this requires a rework and inspection that is not really common. PCBX specializes in the area of advanced SMT and BGA assembly to help drive modern requirements of compact electronic devices.

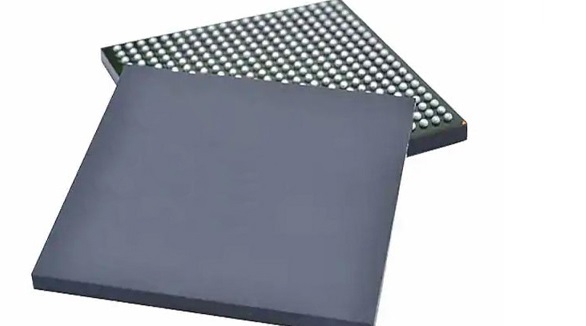

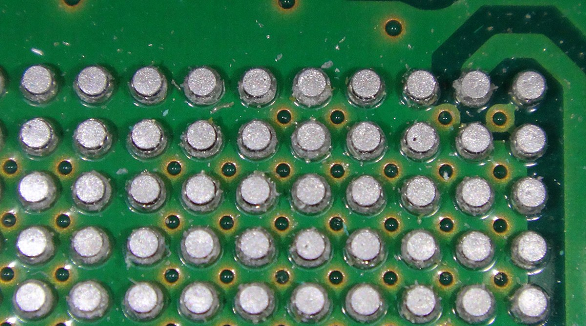

Ball Grid Array (BGA) components, such as PBGA, CBGA, CCGA, TBGA, and CSP, provide high I/O density, improved reliability, and high-quality electrical and thermal performance. Quality assembly and functionality are assured since advanced soldering and inspection methods are required, like AXI and AOI. Proper storage and handling shall guarantee the performance of the devices.

In the late 1980s, when electronics began to shrink, BGA packaging was developed to integrate more connections within a given area. Today, BGA is widely used with high-connection chips—processors being a good example. BGA uses solder balls at the bottom of the chip to connect it to the circuit board. It provides high density along with good heat dissipation and fast signal transmission, one of the main reasons it is ideal for modern electronics. However, it requires precise techniques of soldering in BGA manufacturing.