Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) in PCB manufacturing is crucial for ensuring high-quality, defect-free products, reducing costs, increasing throughput, and enhancing overall process efficiency and reliability.

What is AOI?

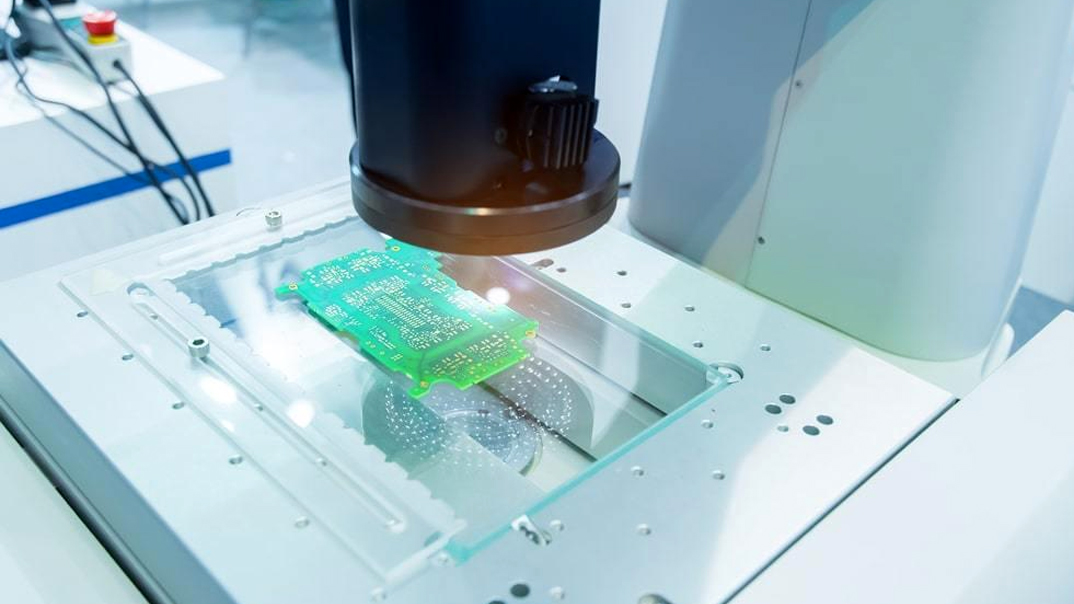

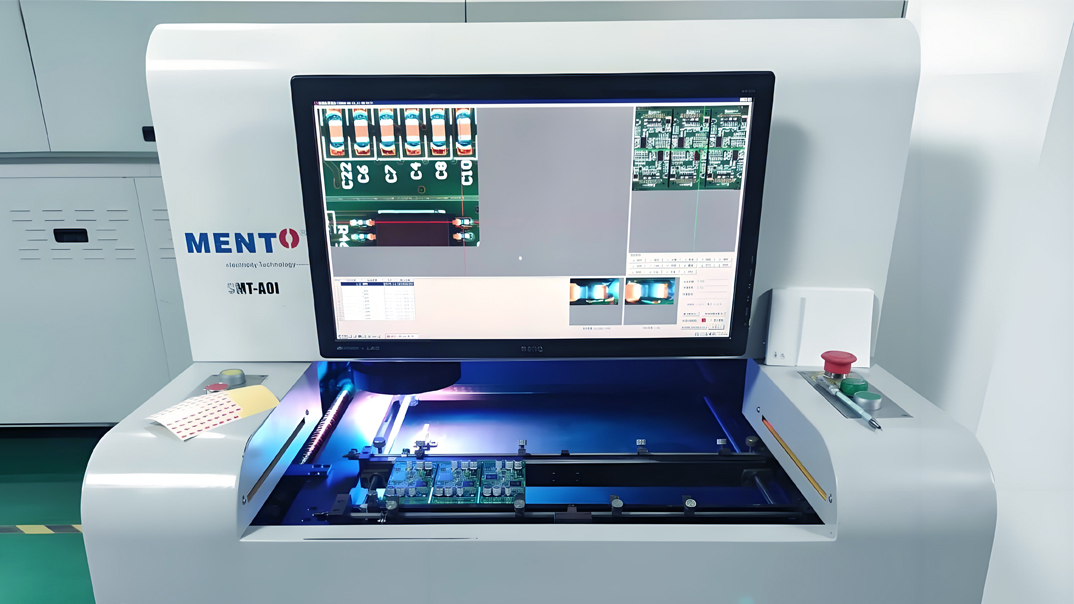

Automated optical inspection (AOI) is a visual quality control approach for detecting faults in PCB manufacturing and assembly operations. The main component of AOI is a CCD camera system that captures images. These images are processed using algorithms through an image processing card and computer software system, compared to standard images to identify defects and generate reports.

This method is used during circuit board inspections to detect surface flaws such as stains, scratches, open circuits, and short circuits. It also checks for the presence and proper arrangement of components, as well as the absence of any missing or wrongly positioned elements.

Imagine a tireless inspector with superhuman vision, scanning thousands of components per second. This isn't science fiction; it's the power of Automated Optical Inspection (AOI).

How Does AOI Work?

The AOI system combines illumination, machine vision cameras, high-definition imaging, and advanced processing software.

Visual Inspection Lighting

Proper lighting is essential for an AOI system to effectively inspect components, as it requires clear visibility to verify various parts and features. While traditional AOI machines utilize different light sources like incandescent, fluorescent, infrared (UR), and ultraviolet lights, modern systems have adopted LEDs for lighting. These LEDs, including red, white, green, and blue ones within a customizable lighting module, offer uniform and consistent illumination.

The angle of lighting is also crucial for optimal inspection. During PCBA processes, taller components may obstruct light from reaching shorter ones, and certain features necessitate low illumination angles. Therefore, an AOI system should integrate light sources from multiple angles to ensure comprehensive and effective lighting coverage.

Machine Vision Camera

In an AOI machine, an automated optical inspection camera captures images of the product and evaluates them using specialized processing software. Modern AOI equipment uses a diverse range of cameras, from extended graphics array (XGA) to high-resolution sensors with millions of pixels. The latest models can even achieve up to 100 frames per second (fps), showing the efficiency of AOI systems in quickly generating large datasets.

Key elements of AOI systems include:

• Optical system resolution: The resolution of the optical system is fundamental in determining the level of detail discernible to the AOI machine. Factors such as detection speed, accuracy, the size of the smallest components on the circuit board, and the specifications of the camera's sensor, lens, and distance to the board significantly influence the system's resolution.

• Field of View (FOV): The FOV is determined by the resolution of the camera sensor and represents the area of the circuit board covered by a single image. A broader field of view allows the circuit board to be scanned with fewer images and at a lower frame rate, whereas a narrower field requires a higher frame rate.

Pros and Cons of AOI

Pros of AOI

Precision and Accuracy

High-powered cameras and advanced systems let it catch tiny flaws human eyes might miss, ensuring top-notch quality with every board.

High-Speed Detection

These automated technologies speed through inspections, saving a significant amount of time by identifying flaws faster than manual examinations. Consequently, workflows become more effective and production is accelerated.

Consistent Reliability

AOI eliminates fatigue from the equation. Unlike human inspectors, it tirelessly scans PCBs for defects, guaranteeing consistent quality.

Detailed Documentation

AOI PCB systems often generate complete inspection results reports, which are critical for quality control. This "traceability" maintains consistent quality and helps to eliminate future issues.

Complex Inspection Capabilities

AOI PCB inspection machines can identify complex components, such as those with fine-pitch parts and elaborate circuitry. Human inspectors may find it difficult to adequately investigate these.

Cons of AOI

Initial Investment Cost

It is the initial investment required for purchasing and implementing the technology.

The high costs can drive demand for large-scale sales, posing a barrier for smaller manufacturers.

False Positives and Negatives

Even the best AOI can miss some defects (false negatives) or flag good parts (false positives). Manufacturers stay on top of updates to minimize these errors.

Inability to Fully Replace Human Judgment

In PCB inspection, human experience is still required for difficult issues such as solder joint quality.

AOI Application

AOI is widely used in electronics manufacturing, including PCB, SMT, and welding quality inspection.

AOI Processing Software

Product inspection relies heavily on the entry of specifications or established standards into the AOI system. These criteria are used as references, or "gold standards," throughout the inspection process. This is achieved through two methods:

- Golden board method: the AOI machine scans a high-quality product through key stages to establish a gold standard for future production.

- Algorithm-based programming: the AOI system can create profiles for products through algorithm-based programming, incorporating product data and specifications directly into its operations.

In conclusion, Automated Optical Inspection (AOI) is a popular and simple approach for PCB inspection that is in high demand due to the electronics industry's rapid rise. In essence, AOI ensures that the board's quality is unaffected.