PCB Shelf Life

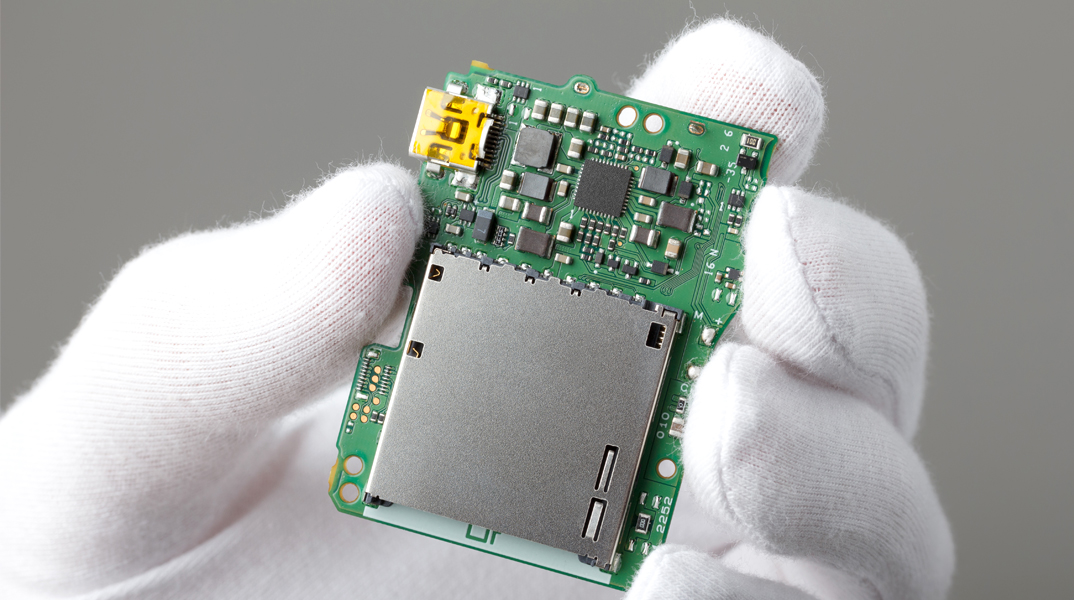

After successfully passed the final product inspection, the PCB can be shipped in vacuum packaging. What is the estimated shelf life of the PCB board under these conditions? In the following section, we will provide you with an overview.

Why is PCB Shelf Life Important?

One of the main risks in the PCB manufacturing process is the complexity of soldering and developing strong solder joints to connect PCB components to the board.

If oxidation occurs, it will negatively affect the soldering process, which is detrimental to the health of the circuit board. Due to such oxidation, solder joints may also become weaker. Therefore, manufacturers consider using PCB components that have the same shelf life as the circuit board to prevent this happening.

The packaging of the PCB during this process also ensures it remaining intact and functional for at least two years. However, it also depends on the type of PCB surface finish you use, because different surface finishes provide different PCB shelf lives.

Assuming PCB boards are stored in vacuum packaging at an ambient temperature of 22±4°C, with humidity controlled between 30%RH-60%RH, the storage durations are as follows:

| Surface Treatment | Storage Duration | Conditions |

| Immersion Silver | Approximately 3 months | Vacuum packaging, 22±4°C, 30%RH-60%RH |

| Immersion Tin | Approximately 3 months | Vacuum packaging, 22±4°C, 30%RH-60%RH |

| OSP | Approximately 3 months | Vacuum packaging, 22±4°C, 30%RH-60%RH |

| Immersion Gold | Approximately 6 months | Vacuum packaging, 22±4°C, 30%RH-60%RH |

| Spray Tin | Approximately 1 year | Vacuum packaging, 22±4°C, 30%RH-60%RH |

Additionally, most of the solders and adhesives used in PCB manufacturing or PCB assembly will also impact the overall shelf life of the PCB.

The Importance of Vacuum Packaging

Vacuum packaging is vital for many PCB manufacturers.

Improper packaging can cause oxidation on the board's surface, affecting soldering and production.

Now, there comes the question, of how to store PCB boards. Unlike other items, keep the boards away from air and water. Protect them during vacuum packaging by wrapping the box's edges with bubble wrap to absorb moisture.

Include moisture-absorbing beads, categorize and label boards correctly, then store the sealed box in a dry, ventilated area away from sunlight and off the ground.

What Affects the PCB Shelf Life?

Understanding the factors that influence the shelf life of PCBs is essential for identifying the factors that are detrimental to your PCBs. Below, you may find the key factors to consider.

- Components - Always insist on using high-quality components to extend the shelf life of the PCB since cheap, low-quality PCB components would only shorten the shelf life of the PCB due to continuous degradation. In addition, substandard PCB parts are also one of the reasons for comprehensive PCB failures and poor electronic performance.

- Surface treatment - The choice of surface cleanliness of PCB will also affect its service life. For example, compared to OSP and other materials, HASL has a longer shelf life for the PCB.

- Soldering - The type of soldering for PCB will also affect the shelf life of the PCB, so it is best to fully research the soldering type of the PCB and its relationship with the shelf life of the PCB.

- Conformal coating - It has a positive impact on the shelf life of the PCB and protects your setup from weather damage, technical complexity, and other issues. It is best to rely on good conformal coatings to address the challenges to the shelf life of the PCB.

- Handling - Problems that occur during the handling of PCBs may shorten their shelf life, as human sweat, PCB detachment, harmful chemicals, low-quality solder paste, and debris can damage the PCB. Experts believe that PCB manufacturers need to design proper methods for handling PCBs to maintain their shelf life as much as possible.

- Transportation conditions - The method of transportation for PCBs is also important here. Unmonitored and reckless transportation of PCBs can damage the structure and may even cause PCB components to detach during transport to your customers and on the way to your customers.

- Storage environment - The temperature of the PCB storage room will also affect them; therefore, always store the PCBs in the optimal environment to minimize damage as much as possible.

The Hidden Risks of Using Expired PCBs

Oxidation

Oxidation can damage PCB structure, leading to incomplete soldering and component detachment. Using effective PCB surface treatments can resolve this issue, but it's crucial to consider the treatments' shelf lives. Choose appropriate surface finishes to ensure strong component connection and resilience to harsh conditions.

Moisture Absorption

Expired PCBs can interact with moisture, causing electrical failures and delamination. Baking can help prevent this but may not work for all PCBs. Using OSP can resolve moisture issues, but reflow soldering should be done promptly after applying OSP to avoid complications.

Conclusion

The shelf life of PCBs is crucial for circuit board health and performance in consumer electronics. There are several key factors affecting it above, so be careful to maintain the shelf life for PCBs.