UL Certification

UL certification is vital in the PCB industry, ensuring safety and reliability. It is a key requirement for market access. This article will explain UL certification, its importance, the certification process, and common standards in the PCB industry.

What is UL Certification?

UL (Underwriters Laboratories), founded in 1894, is a leading institution for safety testing and certification, setting safety standards for products, primarily focusing on areas like fire and electrical safety.

The UL mark is not a quality mark; it is simply a safety certification mark that indicates the product has passed UL's safety tests and complies with safety requirements. Many consumers mistakenly believe that the UL mark represents the highest level of quality. This is incorrect because UL only considers the safety of the product and does not evaluate other performance indicators.

The Importance of UL

In the PCB industry, UL certification is important for a few key reasons:

Safety assurance

UL certification involves strict safety testing and evaluation of PCB materials, components, and manufacturing processes to ensure products meet safety standards, reducing potential safety risks during use.

Enhanced market competitiveness

UL certification is internationally recognized as an authority on safety standards, and many countries require imported products to have UL certification. Therefore, obtaining UL certification for PCB products can ease access to international markets and enhance product competitiveness.

Boost consumer trust

If a PCB product is UL certified, it must meet UL's safety standards, increasing consumer trust in the product.

The UL Certification Process

Apply for UL Certification

To start, you gotta apply for that UL certification badge from the UL company. To get your hands on that badge, you'll need to fill out their application form and hand in the following:

(1) Product specs and tech docs;

(2) Circuit schematics and PCB layouts;

(3) List of key components along with their UL certification numbers;

(4) Samples and test pieces.

1. Pay the fees

After submitting your application, you will have to come up with the required funds. The precise fee varies based on the kind of goods you have and the UL badge you are requesting.

2. Wait for the Once-Over

After you've clicked 'submit,' just wait. UL company will review your docs and samples. During this process, they might ask for more information or samples to dig deeper into testing.

3. Green Light

If all goes well and your application passes muster, you're cleared to slap that UL badge on your product. But hold up, before you start sticking it on, make sure you pay up and comply with all UL company rules and regs.

UL Standards in the PCB industry

In the PCB industry, common UL certification standards include :

UL 796: This standard specifies the safety requirements and testing methods for components such as capacitors, diodes, and transistors on PCB boards.

UL 508 This standard is part of the National Electrical Code (NEC) and specifies the safety requirements and testing methods for PCB boards used in industrial control systems.

UL 60738: This standard specifies the safety requirements and testing methods for components used on PCB boards in medical devices.

By obtaining UL certification, a product's safety and reliability can be enhanced, which helps the product enter international markets, improves brand image, and increases consumer trust.

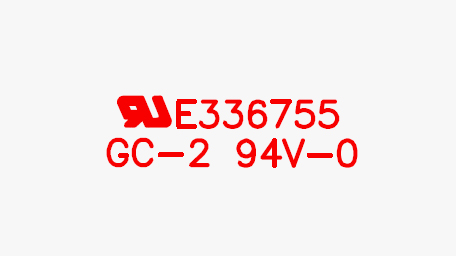

UL certification of PCBX

PCBX manufactures all of its PCBs using a UL 796-certified process.

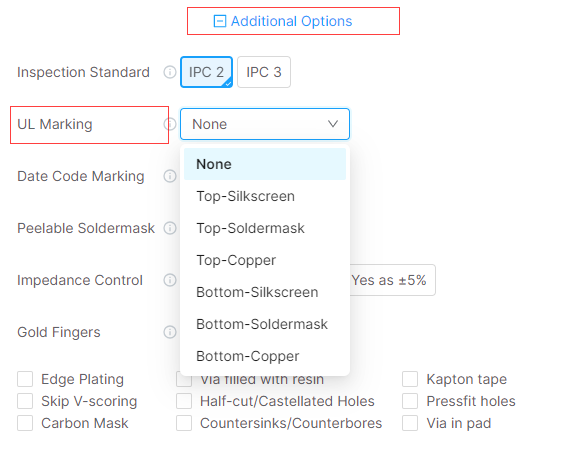

If you want to add UL Marking, select the additional options as shown below.

Above all, UL is a symbol of quality and safety for PCB circuit boards, reflecting manufacturers' commitment to consumers. As technology advances and safety standards evolve, UL certification is increasingly crucial for top-notch electronic products.