PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Serial numbers on PCBs are crucial for traceability, quality control, warranty support, and inventory management, ensuring compatibility and efficient device management.

Low-voltage regulator PCBs are vital for stable power in electronics, enhancing device efficiency and reliability across numerous applications.

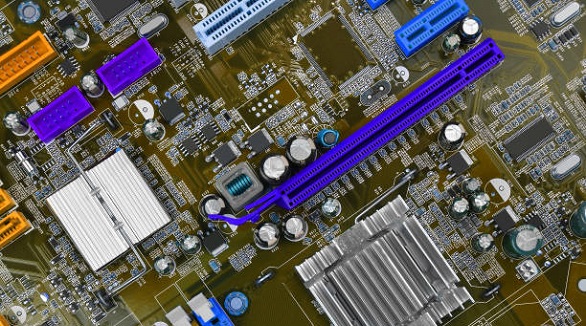

IPC-A-610 ensures global standards for PCB assembly, covering component placement, soldering, labeling, and training, enhancing quality and reliability.

Superior PCBA testing ensures quality, functionality, and reliability, using diverse methods to prevent flaws, maintain standards, and enhance electronics manufacturing.

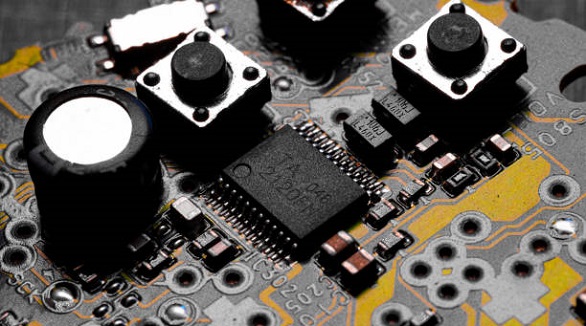

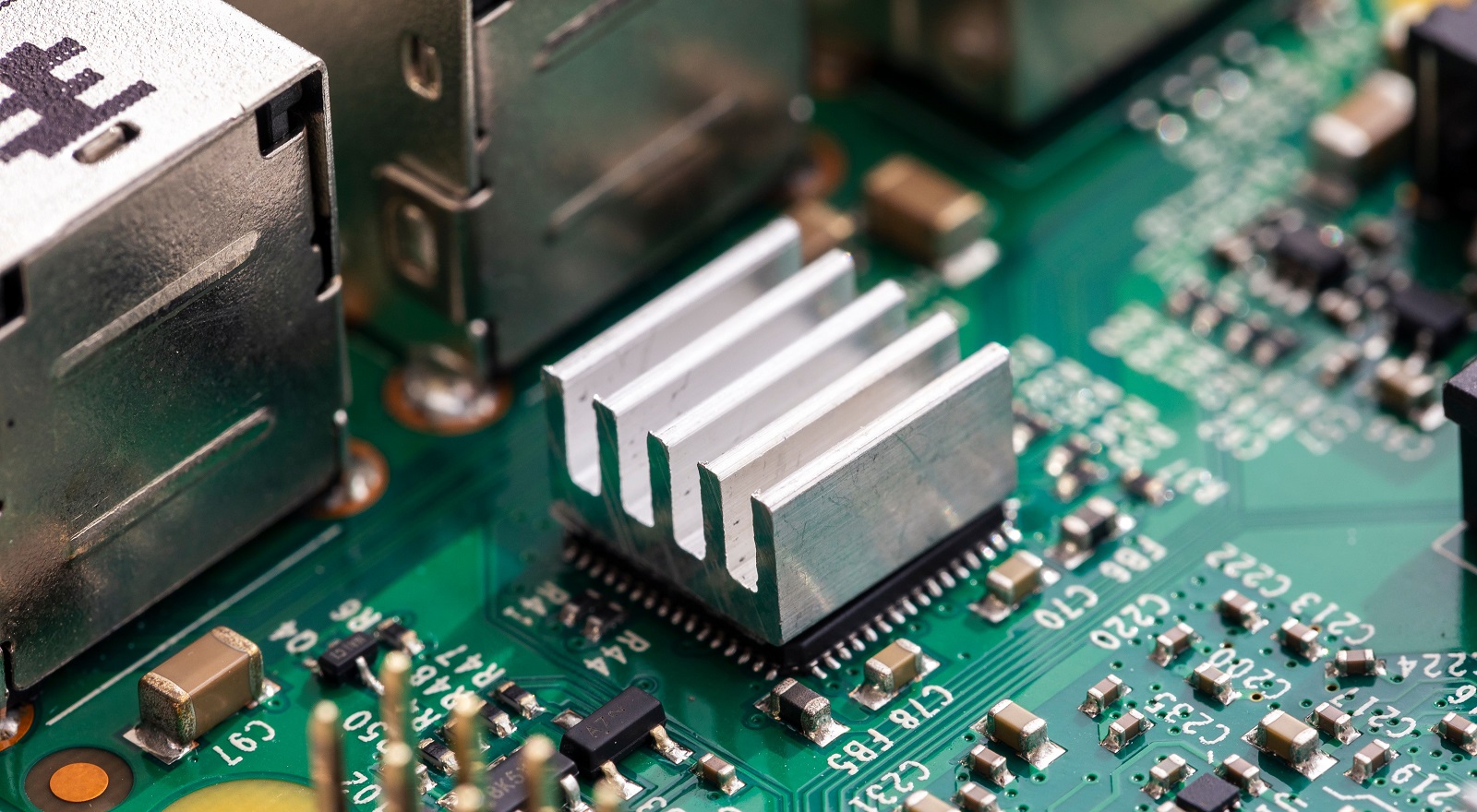

SMD heat sinks dissipate heat to prevent component failure, enhance reliability, and support compact designs, essential for modern, high-performance electronics.

Current limiting circuits are crucial in PCB designs, preventing overcurrent damage and ensuring safe, reliable operation across various electronic applications.

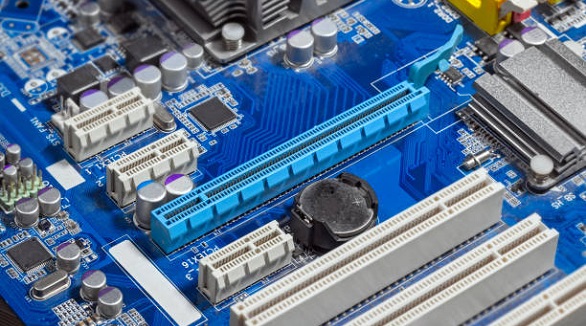

Pin in Paste (PiP) enables efficient, cost-effective PCB assembly, integrating through-hole and surface mount components in a single reflow pass, reducing costs.

Microphone PCBs transform sound to electrical signals using ECM or MEMS tech, focusing on compact, efficient designs for high-fidelity audio applications.