PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Smartwatches enhance life with health, connectivity, and safety features, supported by tech advances and ecosystem integration, driving market growth.

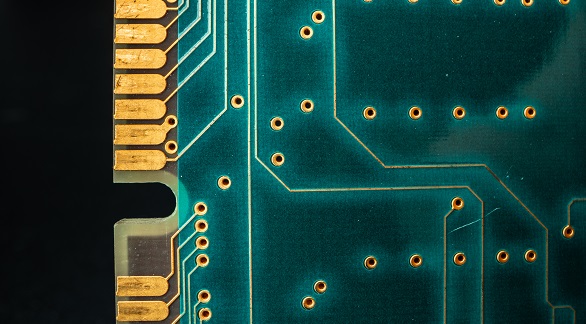

Non-plated through holes provide mechanical support in PCBs but pose stress and precision challenges, requiring careful design, materials, and manufacturing.

IPC standards ensure PCB quality by guiding solder mask application, focusing on material properties, performance tests, classifications, and coverage criteria.

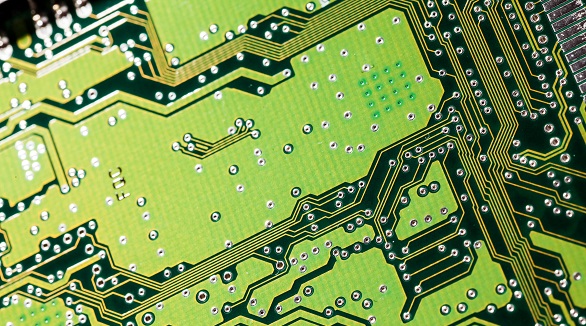

Vias in PCBs connect multiple layers and come in types like through-hole, microvias, blind, and buried. Proper sizing and design optimize PCB performance and reliability, aiding advanced device development.

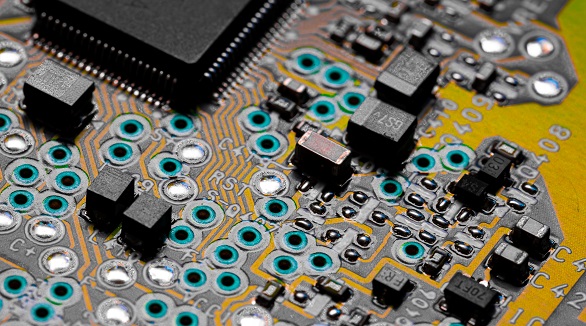

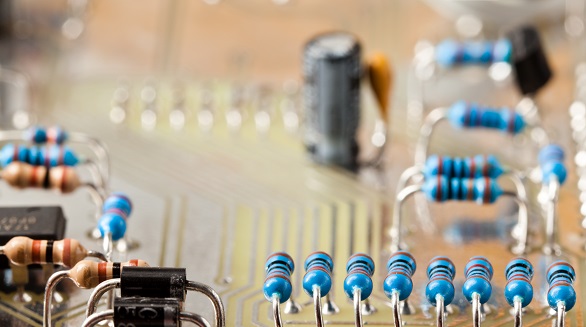

PCBs are crucial in electronics, providing a platform for component interconnection. Mastering component identification ensures effective design, troubleshooting, and maintenance, vital for device reliability and performance.

FR4 is a key PCB substrate with excellent electrical insulation, mechanical strength, and thermal resistance. It's valued for its balance of cost and performance, crucial for a wide range of applications.

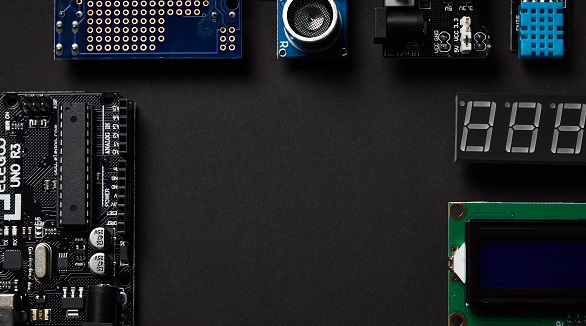

Breadboards and protoboards are key prototyping tools in electronics. Breadboards allow for flexible, solderless circuit design, while protoboards provide durable, soldered connections for finalized designs.

Single-sided PCBs are cost-effective, easy to design and manufacture, quick to produce, reliable, and eco-friendly. Ideal for low-density circuits and simple applications, they offer faster debugging, lower assembly complexity, and reduced short-circuit risk.