PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

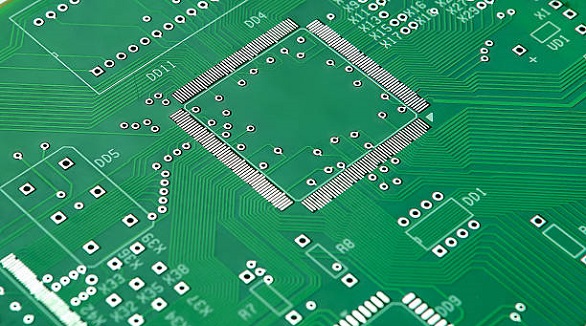

Prepreg is crucial in multilayer PCBs, providing mechanical strength and electrical insulation to meet modern electronics' demanding requirements across industries.

OSP surface finish offers a cost-effective and environmentally friendly solution for protecting copper on PCBs, enhancing solder joint reliability while maintaining performance and enabling reworkability.

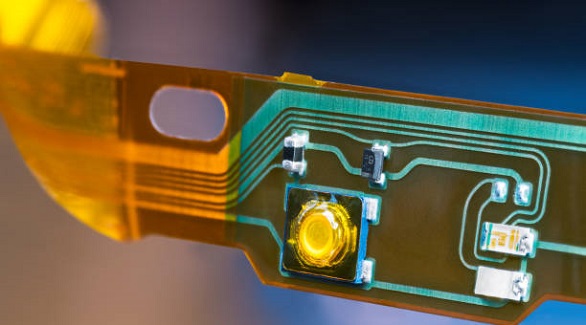

Flex PCB thickness affects performance, offering flexibility, compact design, and durability but demands careful material selection and precise engineering.

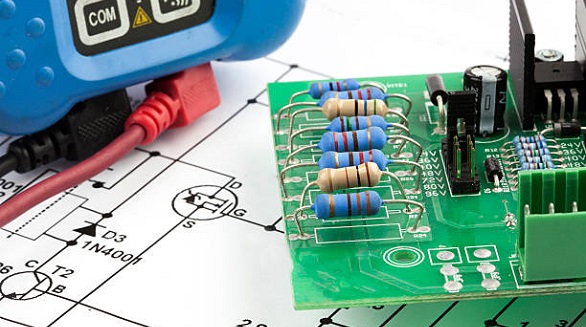

Current limit control circuits safeguard electronics by regulating excess current, ensuring device safety and reliability across various applications and industries.

In the fast-evolving electronics field, PCB performance hinges on dielectric material selection, crucial for signal integrity, thermal management, and reliability.

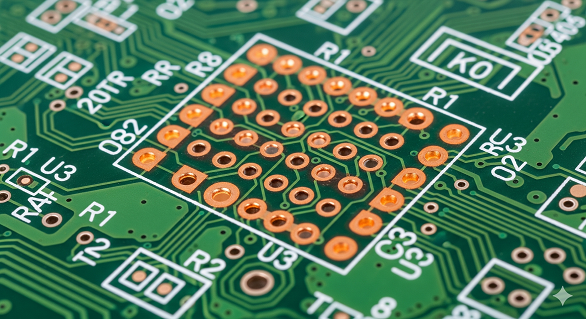

Button plating in flex PCBs enhances flexibility, reliability, and miniaturization, meeting modern design demands for smaller, highly functional devices.

Lead-free solder, safer for the environment, requires higher temps and careful handling; lead solder offers ease but poses health and environmental risks.

White PCBs offer modern aesthetics and enhanced LED efficiency but pose cleaning and inspection challenges, ideal for visually appealing electronics.