PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Fabric circuit boards blend electronics with fabrics, enabling wearables. FCBs offer flexibility, durability, and diverse applications across industries.

Laser tech revolutionizes PCB manufacturing with precision and efficiency, enhancing design, cutting, marking, and connectivity while reducing environmental impact.

Preheating PCBs enhances soldering by reducing thermal shock, improving wetting, and activating flux, using methods like conduction, convection, and IR.

Controlled impedance is crucial in modern PCBs, ensuring signal integrity through precise trace and material design, essential for high-speed applications.

The dielectric constant in PCBs affects signal speed, integrity, and impedance, crucial for optimizing high-frequency circuit performance.

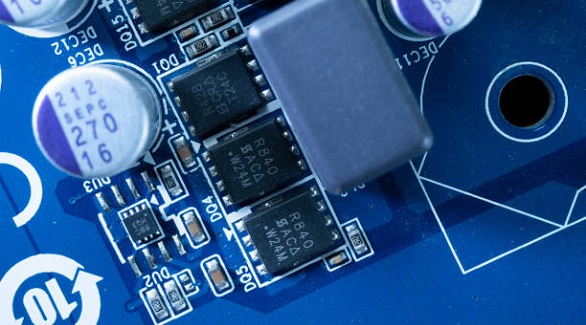

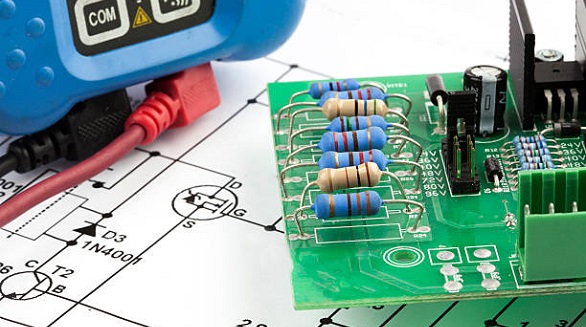

Current limit control circuits safeguard electronics by regulating excess current, ensuring device safety and reliability across various applications and industries.

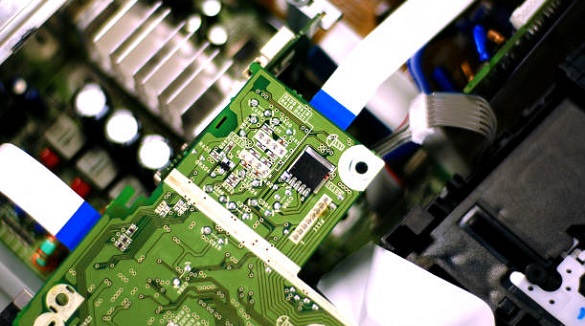

The top manufacturers in wireless network cards drive innovation in connectivity, offering advanced technology for diverse markets, balancing performance, and ease of use.

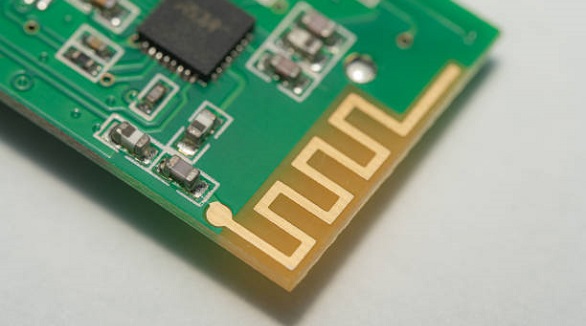

Castellated pads in PCB design facilitate easy board-to-board connections, enhancing miniaturization, assembly, solder quality, and flexibility for compact modules.