PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Serial numbers on PCBs are crucial for traceability, quality control, warranty support, and inventory management, ensuring compatibility and efficient device management.

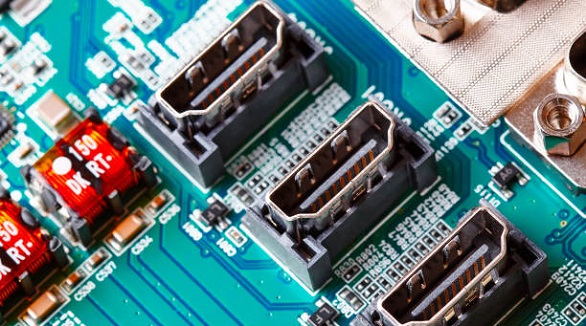

IPC-A-610 ensures global standards for PCB assembly, covering component placement, soldering, labeling, and training, enhancing quality and reliability.

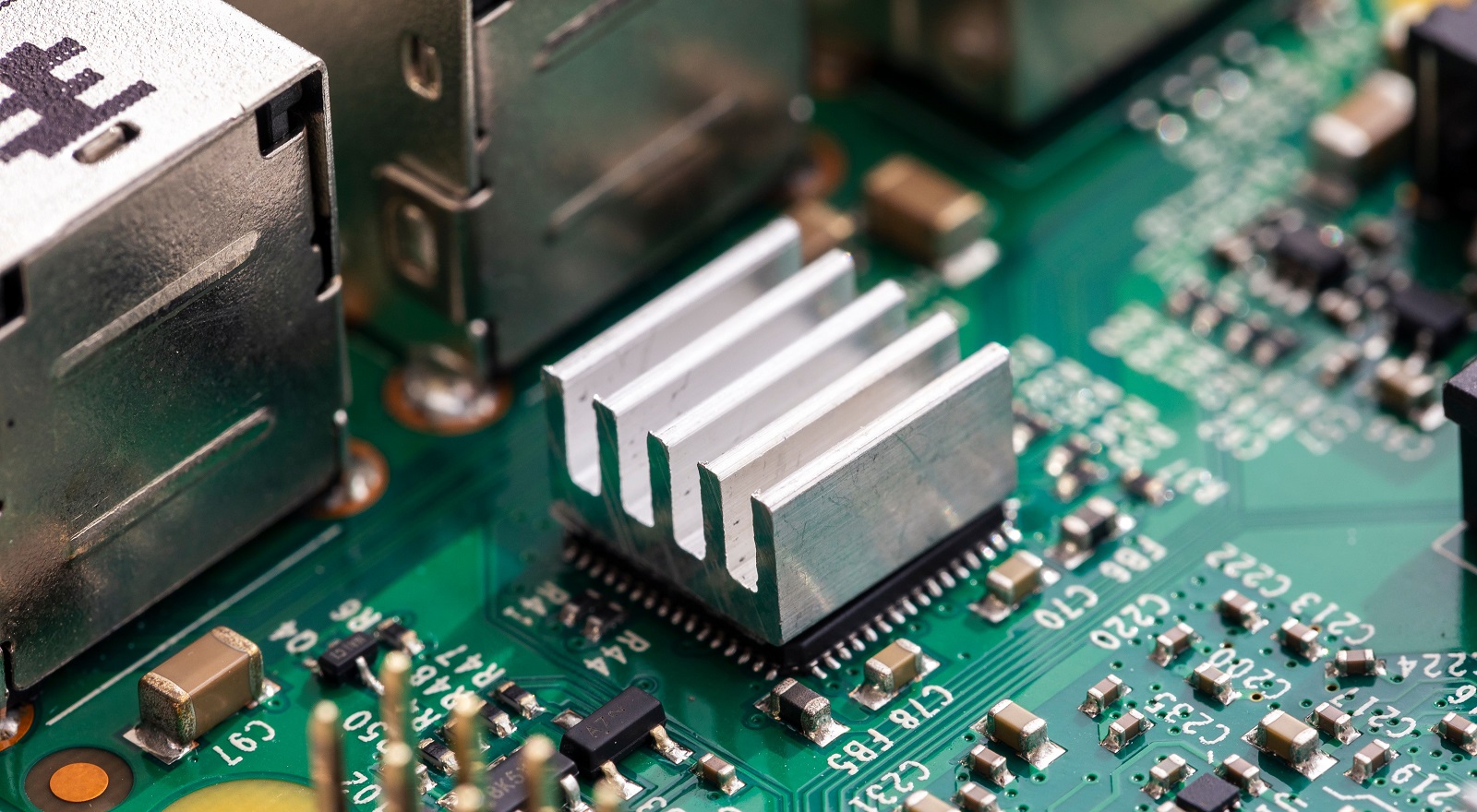

SMD heat sinks dissipate heat to prevent component failure, enhance reliability, and support compact designs, essential for modern, high-performance electronics.

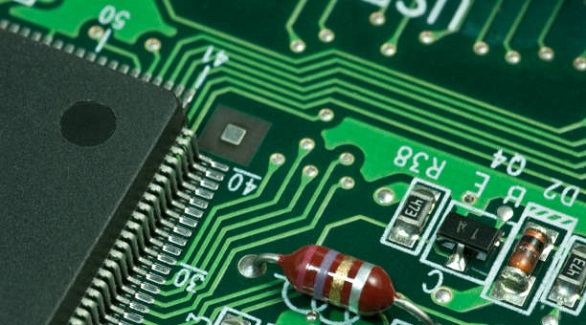

Current limiting circuits are crucial in PCB designs, preventing overcurrent damage and ensuring safe, reliable operation across various electronic applications.

Start-stop circuits efficiently control devices, enhancing safety and performance in industrial and consumer applications through simple push-button mechanisms.

Ground loop control in PCBs is essential to prevent EMI and signal degradation, using ground planes, star grounding, and isolating signal grounds.

PCB test fixtures provide essential connections for precise testing, ensuring PCBs meet design specs and allowing seamless production and quality control.

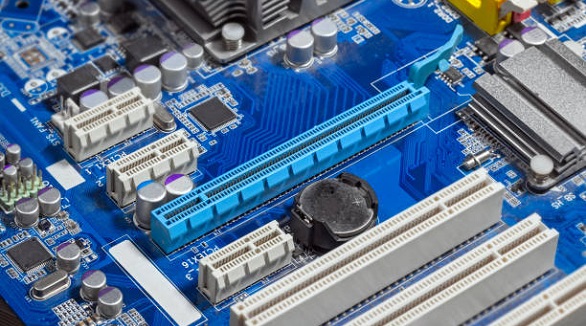

Mounting power supplies on PCBs optimizes space, reliability, and performance. Key factors include layout, thermal management, and mounting methods.