PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Serial numbers on PCBs are crucial for traceability, quality control, warranty support, and inventory management, ensuring compatibility and efficient device management.

IPC-A-610 ensures global standards for PCB assembly, covering component placement, soldering, labeling, and training, enhancing quality and reliability.

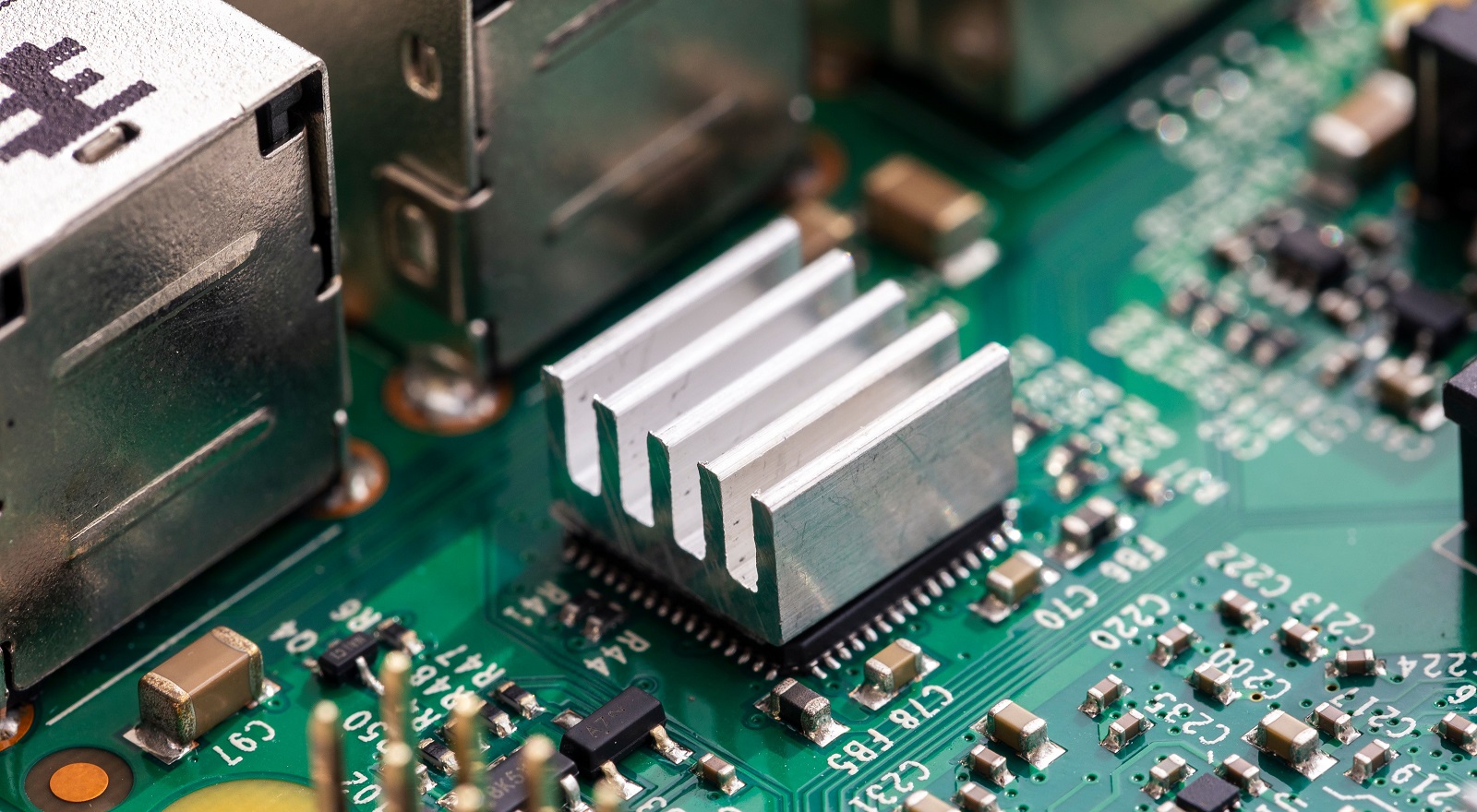

SMD heat sinks dissipate heat to prevent component failure, enhance reliability, and support compact designs, essential for modern, high-performance electronics.

ARM processors are efficient and flexible, ideal for many applications, while FPGAs offer custom parallel processing, crucial for specialized tasks requiring flexibility.

IPC-A-600 standard guides PCB quality through three class levels, ensuring durability and reliability for diverse applications, crucial for manufacturers.

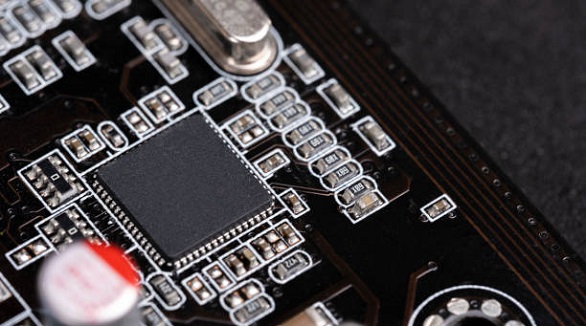

Embedded PCB components enhance space efficiency, reliability, and performance, driving innovation in compact electronics for consumer, automotive, and medical applications.

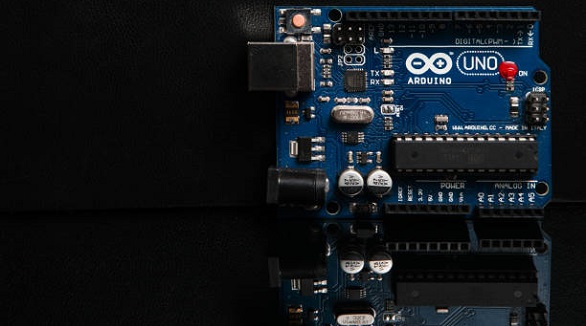

Arduino Leonardo and UNO both excel in electronics, with Leonardo suited for HID and USB projects, while UNO is cost-effective for beginners and simple tasks.

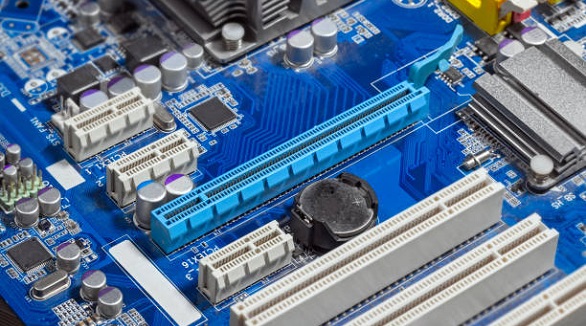

Power and ground planes in PCBs ensure signal integrity, manage heat, and minimize EMI, crucial for efficient, high-performance electronic devices.