PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

SMT revolutionizes electronics by enabling smaller, efficient, durable devices, with reduced costs and performance boosts, essential in various industries.

Ensure SMT quality through detailed design, supplier rigor, and process controls, enhanced by testing and continuous improvement for reliable, defect-free products.

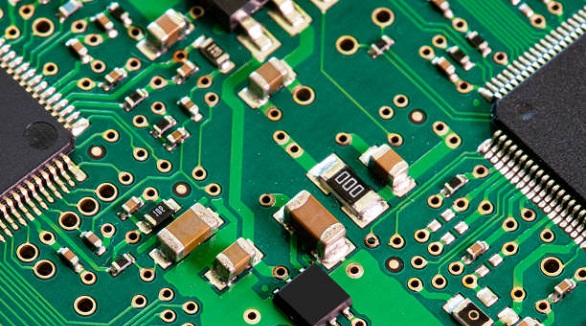

SMD resistors are crucial for modern electronics, enabling compact, high-density designs, efficient automated manufacturing, and improved high-frequency performance, driving technological advancement.

Precision in PCB stencil manufacturing is crucial for accurate solder paste deposition, reducing defects, and improving reliability. Key factors include material, technology, design, and maintenance.

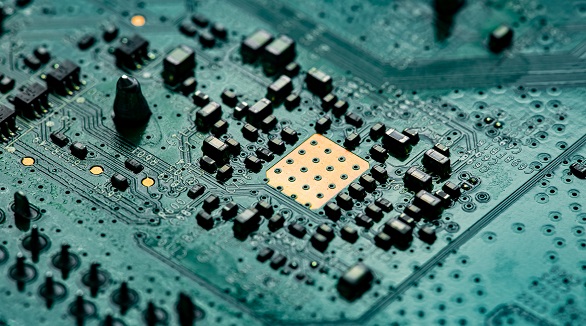

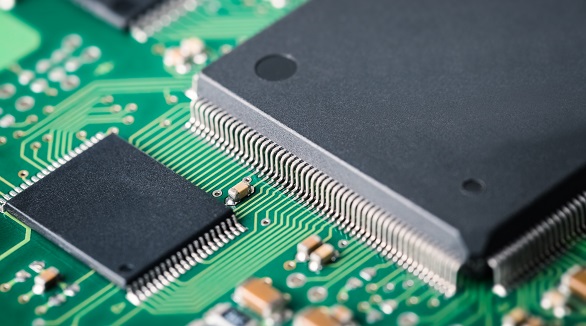

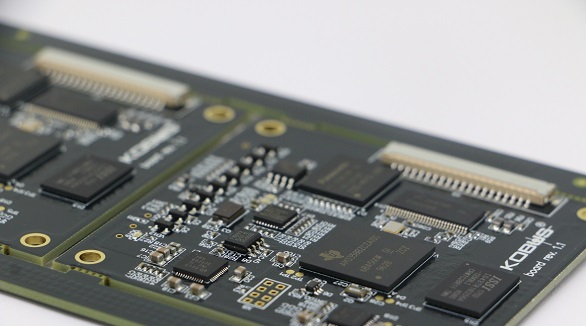

Surface Mount Technology (SMT) revolutionized electronics, facilitating smaller, faster, and more reliable products. It mounts components directly on PCBs, enabling miniaturization and automation. Though SMT boosts space efficiency, cost-effectiveness, and reliability, it poses rework challenges and requires high initial investment.

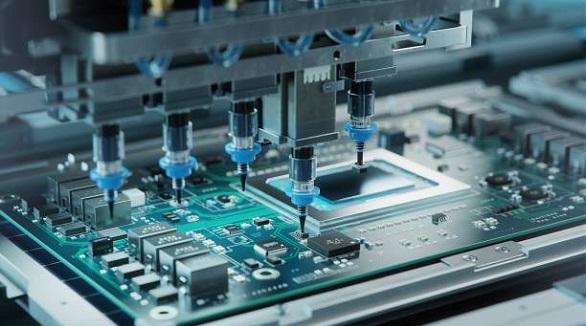

SMT assembly places components directly on PCBs, enhancing miniaturization, performance, and efficiency. Key steps: solder paste printing, chip mounting, reflow soldering, and inspection.