PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Controlled impedance is crucial in modern PCBs, ensuring signal integrity through precise trace and material design, essential for high-speed applications.

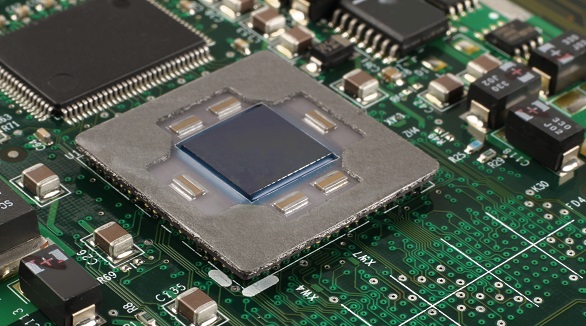

ARM processors are efficient and flexible, ideal for many applications, while FPGAs offer custom parallel processing, crucial for specialized tasks requiring flexibility.

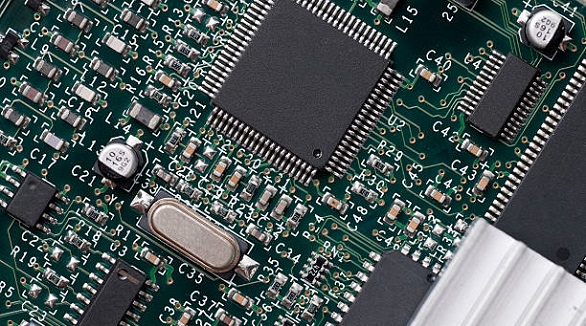

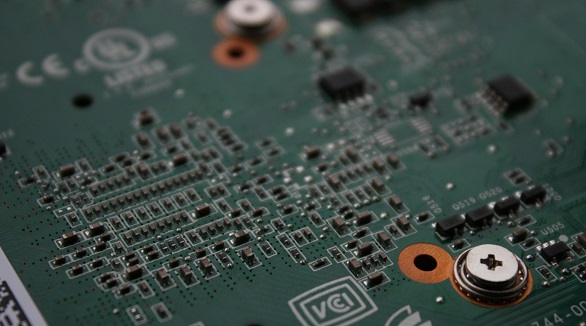

The main PCB is crucial for mounting and connecting electronic components, vital for device performance. It supports design and manufacturing innovations.

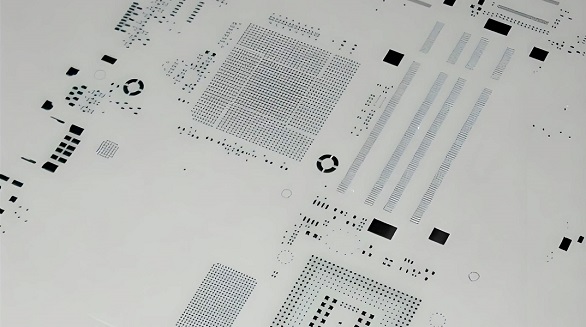

PCB stencils ensure precise solder paste application, vital for strong connections and efficient SMT assembly, reducing errors and enhancing product quality.

Fiducial marks ensure precise PCB component placement, enhancing manufacturing accuracy, efficiency, and reliability, essential in critical sectors like aerospace.

Ceramic Substrate PCBs boost innovation with superior heat management, strength, and miniaturization, making them vital in electronics across industries.

COB technology mounts chips directly on PCBs without packaging, reducing size and weight while improving performance and thermal management, ideal for compact devices like wearables and LEDs.

Solder paste stencils are crucial for accurate PCB assembly, offering precision and reduced defects. Various types, including laser-cut and hybrid, enhance manufacturing efficiency and product reliability.