PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

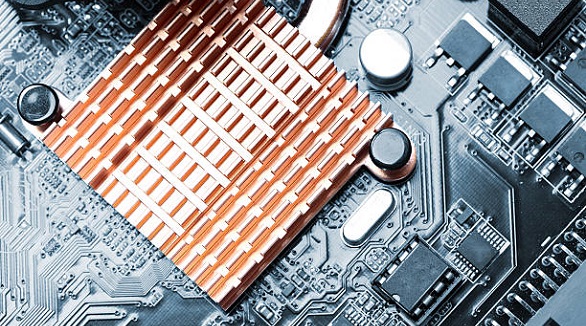

Copper wrap plating enhances PCB reliability and performance by strengthening connections, reducing thermal stress, and meeting industry standards like IPC 6012E.

Copper weight determines PCB effectiveness in conductivity, thermal management, and mechanical strength, essential for high performance in various applications.

Aluminum PCBs excel in thermal management and mechanical strength for high-performance uses, but FR4 offers better electrical insulation and lower cost.

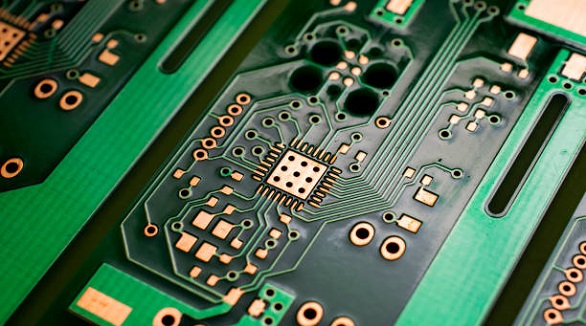

PCB printing services are crucial for transforming complex designs into efficient parts, offering precision, cost savings, and access to advanced technologies.

Mastering hot air rework to remove SMD chips ensures precise control, protects the PCB, and is vital for effective electronics repair and upgrades.

Aluminum PCBs offer cost-effective thermal management for moderate applications, while copper PCBs excel in high-performance electrical and thermal tasks.

3 oz copper PCBs are rising in popularity due to enhanced conductivity, thermal management, and durability for high-power applications, despite added costs.

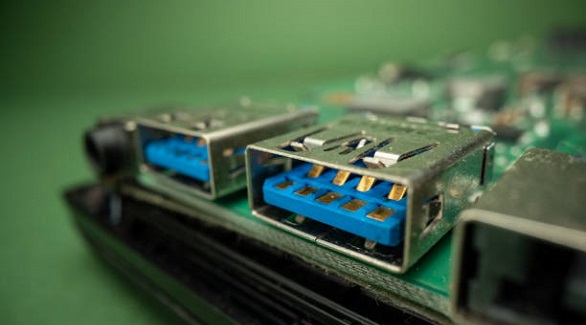

USB Host Shields expand microcontroller functionalities by enabling USB connectivity, crucial for applications in DIY projects, IoT, and prototyping environments.