PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

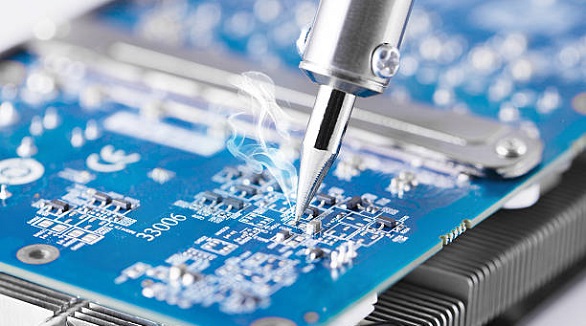

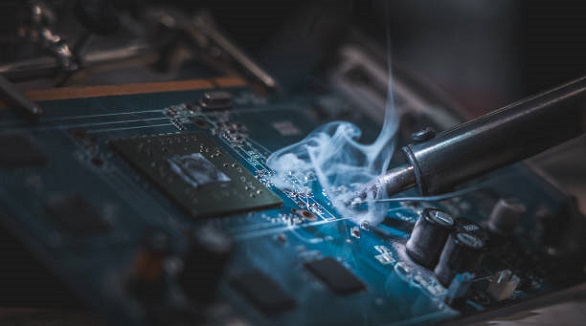

Soldering is vital for connecting components on PCBs in electronics, employing techniques like hand, wave, and reflow soldering to ensure reliable assemblies.

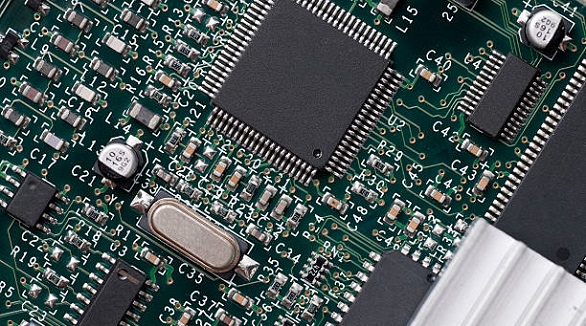

PTH soldering provides strong connections by threading component leads through PCB holes, requiring meticulous preparation and quality checks for lasting results.

Dry solder joints in PCBs cause unreliable connections, leading to device failure. Prevent with proper heat, cleaning, quality solder, and skilled techniques.

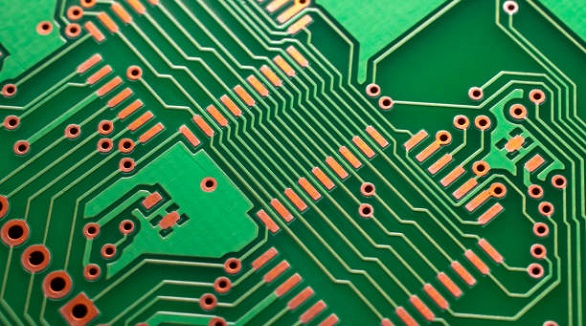

Controlled impedance is crucial in modern PCBs, ensuring signal integrity through precise trace and material design, essential for high-speed applications.

Explore solder selection for circuit boards: understand types, best brands, and safety tips to ensure strong, reliable connections and optimal performance.

PCB soldering requires precise temperature control for reliable connections. Techniques like SMT and reflow soldering use specific temperature profiles to ensure quality.

The main PCB is crucial for mounting and connecting electronic components, vital for device performance. It supports design and manufacturing innovations.

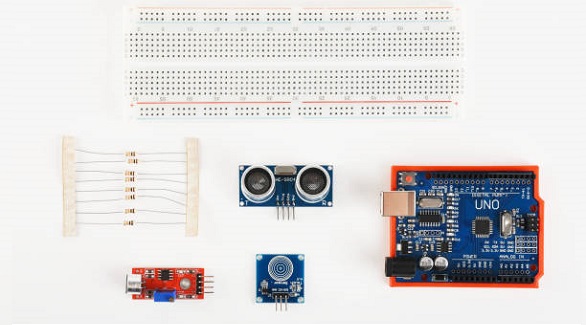

Solderable breadboards offer stable, permanent circuit solutions ideal for prototyping, education, and hobbies, balancing flexibility and long-term use in electronics.