PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

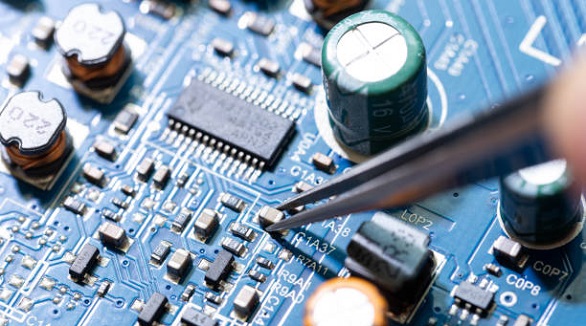

Master soldering chip components on PCBs using proper tools and techniques, ensuring precision and reliability for both hobbyists and professionals in electronics.

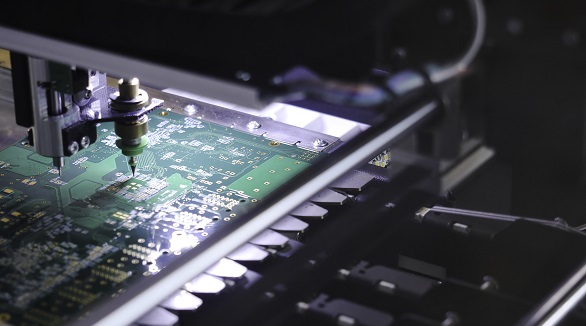

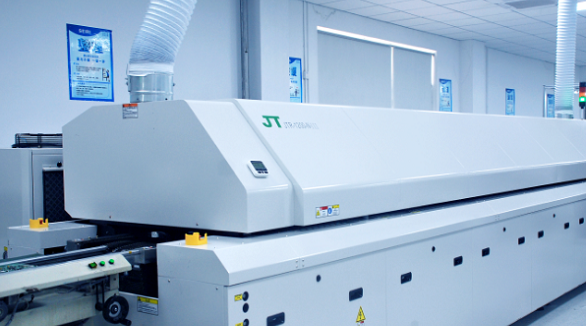

Selective soldering offers precision and efficiency for complex PCB assemblies, targeting specific areas with improved quality, cost-effectiveness, and flexibility, overcoming limitations of wave soldering.

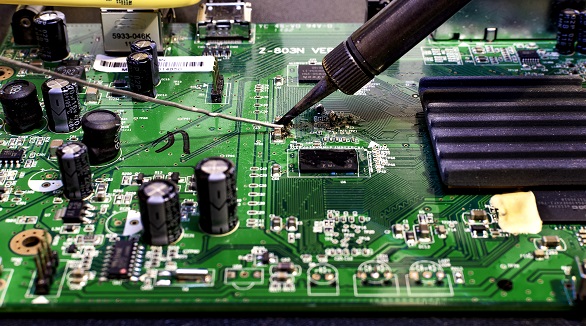

Reflow soldering is vital for PCB assembly but faces challenges like solder bridging, tombstoning, and voiding. Effective solutions include optimized stencil design, thermal profiling, and precise component placement.

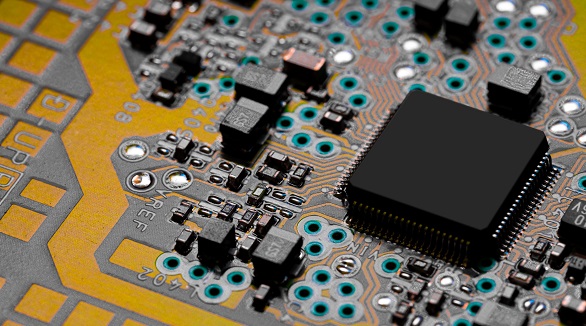

SMD soldering mounts small components on the PCB surface for compact, automated designs but has high setup costs and repair challenges. DIP soldering uses through-hole components for robust, easily repairable, lower-volume applications.

The article provides a step-by-step guide to soldering a PCB, covering workspace setup, essential tools, and safety measures. It explains heating the soldering iron, applying flux, tinning the iron tip, placing components, heating joints, applying solder, cooling, inspecting, and cleaning. Emphasis is on practice and safety for successful soldering.

The article introduces the SMT (Surface Mount Technology) assembly process and future trends. Key steps include solder paste printing, chip mounting, reflow soldering, cleaning, inspection, and rework. Future trends highlight fast, flexible systems, green practices, and high-efficiency, intelligent systems. SMT's potential revolutionizes electronics manufacturing with wide industrial applications.

Soldering forms a very important part in the assembly of a PCB. Wave soldering is ideally applied in Through-Hole Technology, while reflow soldering in Surface Mount Technology. Wave soldering involves flux spraying, pre-heating, soldering, and cooling, while in the case of reflow soldering, pre-heating, thermal soak, soldering, and cooling steps are applied. Temperature and time control are the two most critical parameters in the above-mentioned techniques for ensuring soldering reliability.