PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

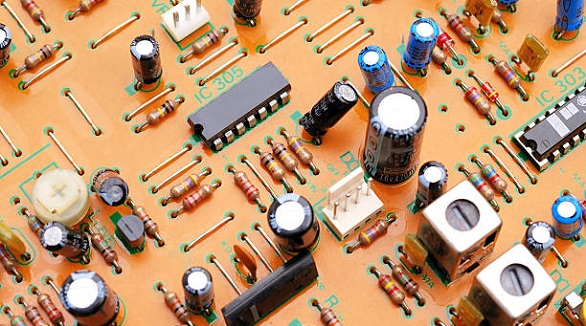

Through-hole assembly remains essential in electronics, offering strength and reliability, especially in critical applications, despite SMT's rise in compact designs.

In-Circuit Testing ensures PCB reliability by verifying component integrity and connections, with advantages in accuracy and coverage, but high setup costs.

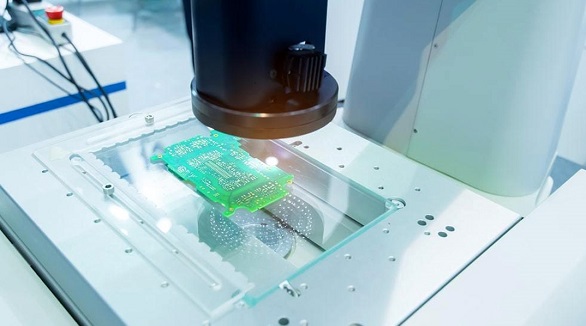

With SMT assembly at the forefront of electronics manufacturing, advanced inspection technologies like visual, AOI, ICT, and X-ray are essential due to increasing component complexity. Inspections throughout all stages—incoming, process, and post-reflow—address defects, ensuring quality and reducing rework.

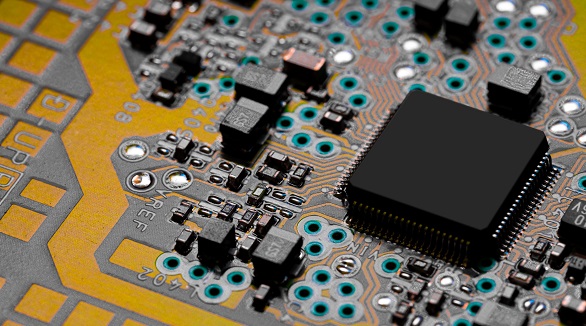

The article introduces the SMT (Surface Mount Technology) assembly process and future trends. Key steps include solder paste printing, chip mounting, reflow soldering, cleaning, inspection, and rework. Future trends highlight fast, flexible systems, green practices, and high-efficiency, intelligent systems. SMT's potential revolutionizes electronics manufacturing with wide industrial applications.

As PCBs and components shrink, AOI (Automated Optical Inspection) replaces visual inspection in SMT assembly, ensuring high-quality solder joint performance through intelligent, optical techniques.

As PCB lines and components shrink, traditional visual inspection fails; AOI using DRC and CAD methods is crucial for quality SMT assembly, offering intelligent, accurate inspections.