PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

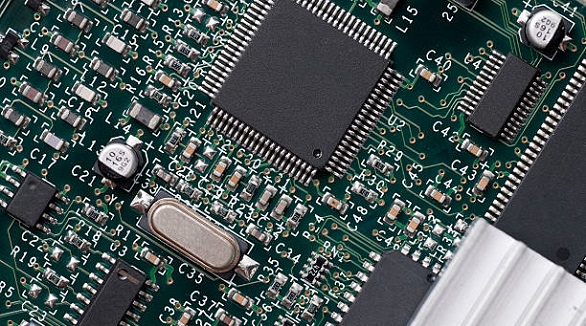

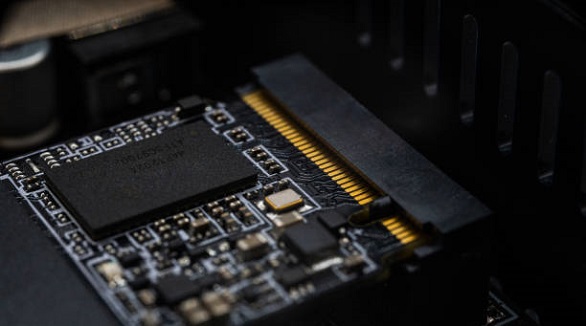

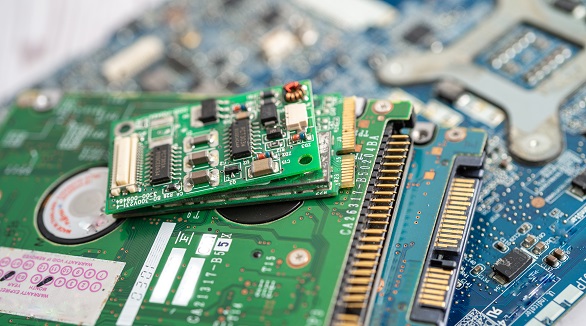

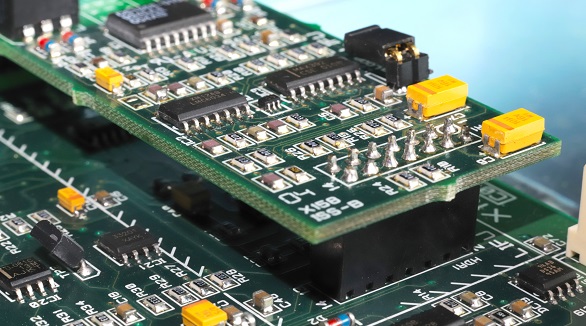

The main PCB is crucial for mounting and connecting electronic components, vital for device performance. It supports design and manufacturing innovations.

Thermocouples in PCBs ensure accurate temperature monitoring; attach with solder, tapes, or epoxy based on application needs for effective thermal management.

Black FR4 PCBs offer aesthetic and functional benefits, including light blocking, heat dissipation, and enhanced signal performance, suitable for electronics.

ENEPIG is a high-performance PCB finish with nickel, palladium, and gold layers, offering superior solderability, corrosion resistance, and wire bonding for critical industries like aerospace and telecom.

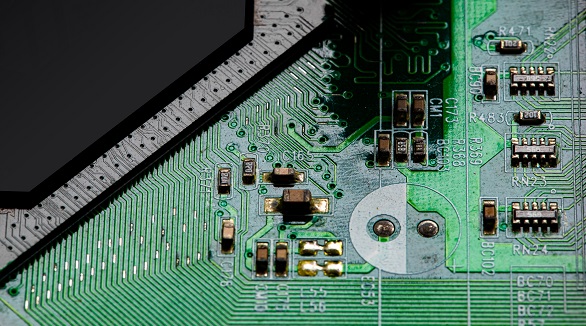

Solder mask, or solder resist, is the polymer layer on PCBs that protects against oxidation, short circuits, and solder bridges. Types include LPI, dry film, and epoxy, chosen based on design, application, and cost.

Copper in PCBs oxidizes, causing solder defects and reducing product life. Surface coatings like HASL, OSP, ENIG, and ENEPIG prevent this, ensuring solderability and reliability. Choosing the right coating based on application needs significantly improves the quality, reliability, and lifespan of products.

The silkscreen layer, made of non-conductive ink, is vital for identifying PCB components and ensuring accurate placement. Methods like Liquid Photo Imaging and Direct Legend Print enhance precision. PCBX excels in producing high-quality silkscreen applications, crucial for proper assembly and functionality.

Selecting the right PCB surface finish, from options like HASL, ENIG, ENEPIG, and OSP, is crucial for preventing oxidation, ensuring solderability, and meeting reliability standards.