PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

TQFP packages optimize PCB layout with space efficiency, RoHS compliance, and high reliability, addressing die shrinking and enhancing portability.

PCB schematics map circuit connections, while layouts focus on physical design for manufacturing. Both stages ensure optimal and reliable PCB design.

The dielectric constant in PCBs affects signal speed, integrity, and impedance, crucial for optimizing high-frequency circuit performance.

Nets in PCB design ensure logical connections from schematics to layout, enabling connectivity checks, design validation, and optimized manufacturing processes.

PCBs are crucial in transforming energy grids into smart, efficient systems, optimizing renewable integration and energy management for a sustainable future.

Select aluminum PCBs for excellent heat management or FR4 PCBs for cost-effective versatility in diverse electronic applications.

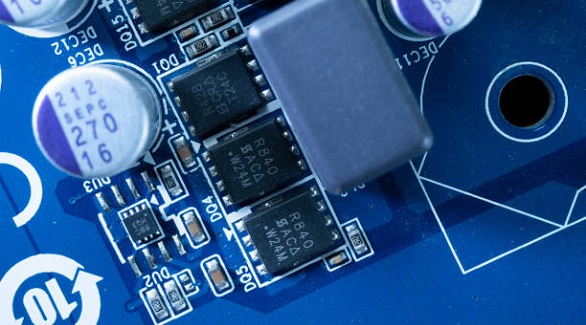

Power and ground planes in PCBs ensure signal integrity, manage heat, and minimize EMI, crucial for efficient, high-performance electronic devices.

Smart switches enhance home automation with features like voice control, remote access, and energy monitoring, using PCBs for efficiency and connectivity.