PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

PCBs require rigorous reliability testing to ensure long-term durability, performance across industries, and standards compliance, minimizing failure risks.

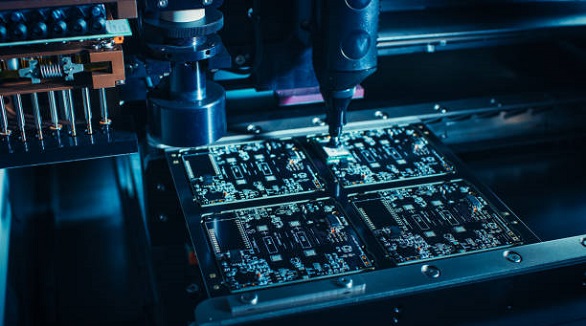

SMT contract manufacturing offers cost-efficient, high-quality PCB assembly, allowing businesses to focus on core strengths and adapt to market changes effectively.

PCB layout design transforms schematics into reliable, efficient electronic products by optimizing signal integrity, power distribution, and thermal management.

In PCB manufacturing, DFM Checks ensure efficient production by identifying design issues early, reducing costs, enhancing quality, and preventing delays.

Low-voltage regulator PCBs are vital for stable power in electronics, enhancing device efficiency and reliability across numerous applications.

IPC-A-610 ensures global standards for PCB assembly, covering component placement, soldering, labeling, and training, enhancing quality and reliability.

Superior PCBA testing ensures quality, functionality, and reliability, using diverse methods to prevent flaws, maintain standards, and enhance electronics manufacturing.

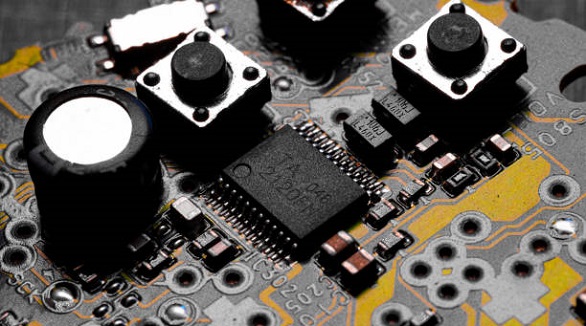

TQFP packages optimize PCB layout with space efficiency, RoHS compliance, and high reliability, addressing die shrinking and enhancing portability.