PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

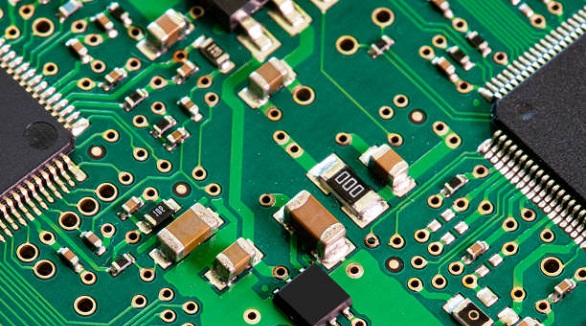

SMT footprints are critical PCB designs for mounting components directly, ensuring electrical connections and standardization, aiding efficient manufacturing.

SMT revolutionizes electronics by enabling smaller, efficient, durable devices, with reduced costs and performance boosts, essential in various industries.

SMT assembly streamlines electronics manufacturing with compact, reliable designs using precise equipment, meeting high-density demands and international standards.

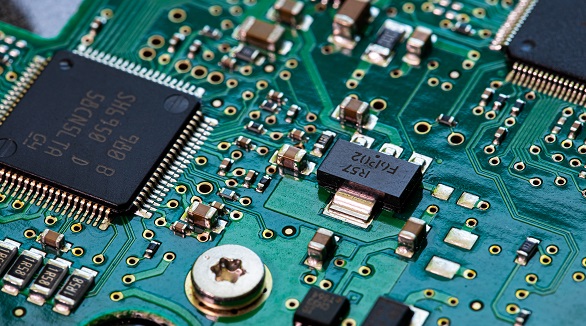

The article compares Ball Grid Array (BGA) and Land Grid Array (LGA) packaging technologies for mounting microprocessors on PCBs. It details their pros and cons, applications, and factors to consider for optimal design choices.

Through-hole assembly is a key PCB manufacturing technique offering reliability and mechanical strength. This article details design elements, requirements, and standards, including thermal pads, IPC performance levels, component types, solder joint quality, hole sizes, and annular ring dimensions, ensuring robust and manufacturable PCBs for various applications.

Optimize PCB design, use through-hole vias, reduce layers, choose economical finishes, and minimize board size. Create detailed BOMs, order in bulk, avoid rush orders, ensure rigorous testing, compare providers, use automation, and consider turnkey services for cost-effective PCB assembly.

Key factors influencing PCB assembly cost include labor, turnaround time, quantity, technology, packaging, board size, material choice, layers, hole size, and finish. Manage costs by optimizing design, ordering in bulk, selecting suitable materials, and negotiating lead times.