PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

The 94V-0 circuit board ensures safety in electronics by meeting fire resistance standards, essential for compliance, reliability, and reduced liability in devices.

Preventing dendrite growth and contamination in PCBs is vital for reliability; effective testing and controls ensure longevity and performance in electronics.

Reduce PCB noise for reliable analog signals with organized design, strategic layout, component selection, and targeted noise management techniques to enhance performance.

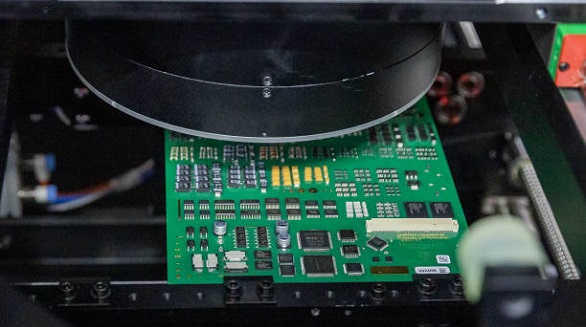

Mastering hot air rework to remove SMD chips ensures precise control, protects the PCB, and is vital for effective electronics repair and upgrades.

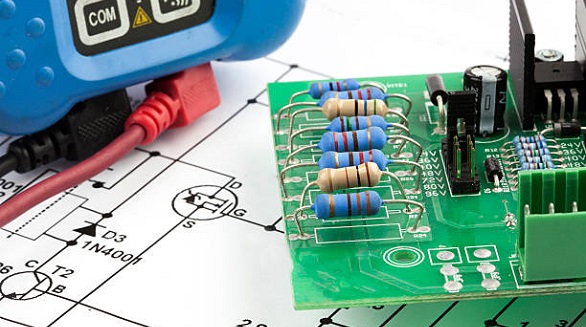

Current limit control circuits safeguard electronics by regulating excess current, ensuring device safety and reliability across various applications and industries.

Effective management of load current in PCBs ensures reliability and safety, essential for modern technology across sectors like communications and medical devices.

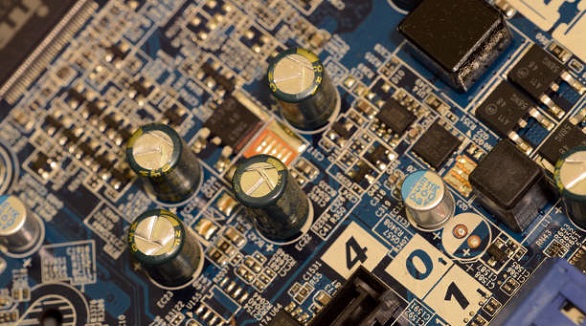

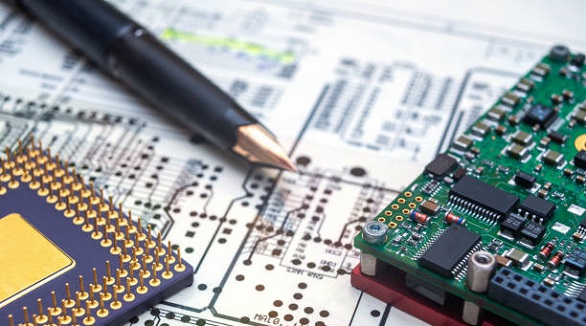

PCB design demands precision, using subcircuits for optimized layout, managing thermal concerns, and minimizing signal paths to ensure performance and manufacturability.

Achieving PCB stability involves balancing design precision and costs through techniques like GD&T, balanced stack-ups, and even metal distribution for reliability.