PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

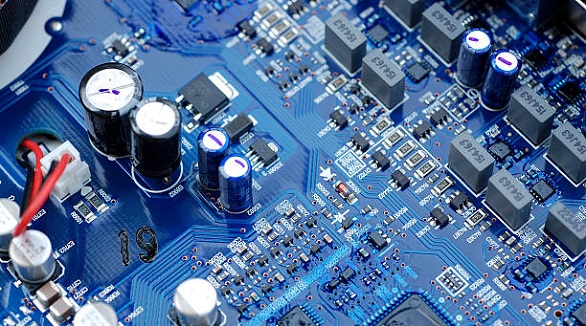

Ground loop control in PCBs is essential to prevent EMI and signal degradation, using ground planes, star grounding, and isolating signal grounds.

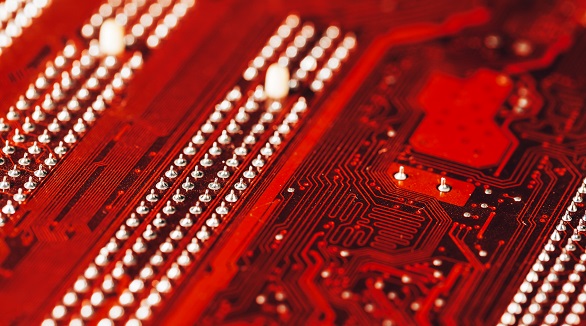

Red PCBs offer aesthetic and functional benefits like enhanced visibility and noise reduction, making them a versatile choice despite green's dominance.

PCB aspect ratio, relating board thickness to via diameter, is key for quality, cost, and reliability in manufacturing, impacting plating and design.

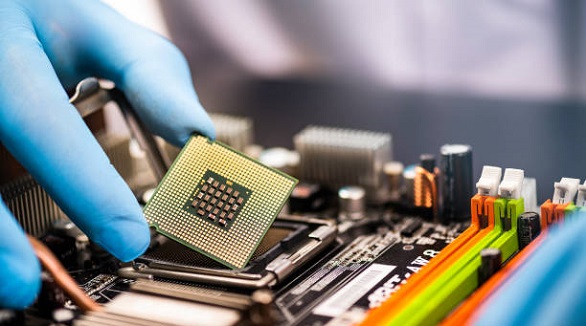

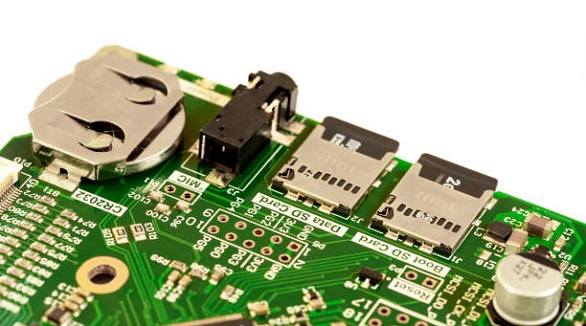

PCB kits are essential for hobbyists and students, offering all components to easily assemble and test functional electronics, enhancing practical learning.

Component shelf life is crucial for device reliability. Proper storage, handling, and management prevent failures, ensuring optimal performance and longevity.

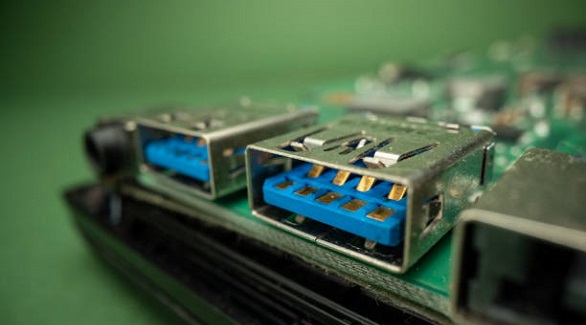

PCB edge mounting optimizes space, enhances modularity, and improves connectivity by placing connectors on board edges, aiding in flexible, efficient system design.

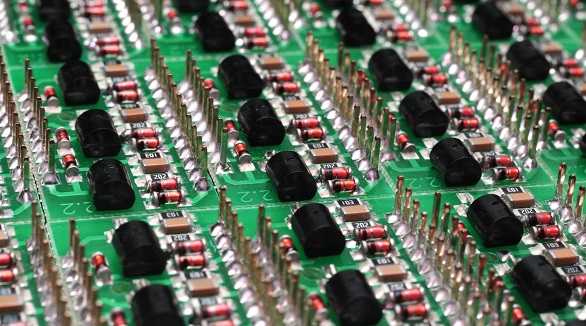

Burn-in boards are vital for testing semiconductor reliability, simulating stress to reveal defects, ensuring high-quality devices before mass production.

USB Host Shields expand microcontroller functionalities by enabling USB connectivity, crucial for applications in DIY projects, IoT, and prototyping environments.