PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Smart door locks advance home security with convenience and tech, utilizing PCBs for functions like connectivity and access, critical to smart home growth.

ESD standards like ANSI/ESD S20.20 protect electronics from electrostatic damage, ensuring product reliability and reducing risks in manufacturing.

CTI measures PCB material's resistance to electrical tracking, ensuring safety and reliability in electronic circuits, crucial for design and manufacturing.

PCB edge mounting optimizes space, enhances modularity, and improves connectivity by placing connectors on board edges, aiding in flexible, efficient system design.

Burn-in boards are vital for testing semiconductor reliability, simulating stress to reveal defects, ensuring high-quality devices before mass production.

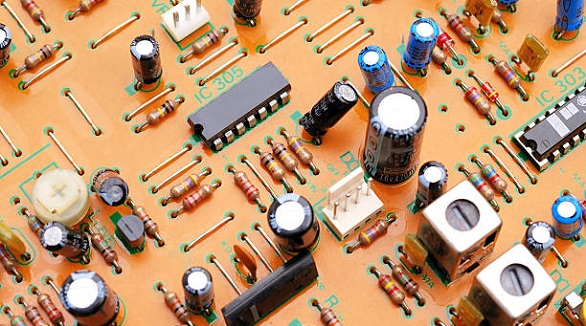

Through-hole assembly remains essential in electronics, offering strength and reliability, especially in critical applications, despite SMT's rise in compact designs.

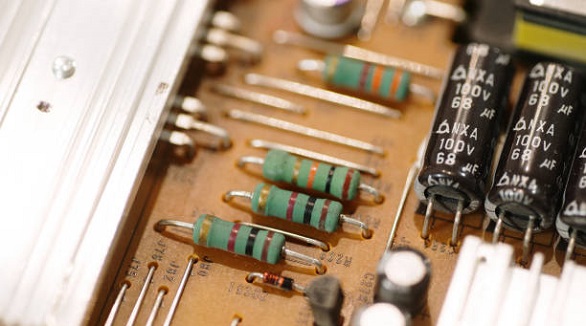

Diodes control current flow in circuits. Regular testing using tools like multimeters ensures performance, reliability, and protection of electronic components.

Solder masks protect PCBs, while paste masks aid precise component placement during assembly, both crucial for PCB reliability and efficiency in electronics.