PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

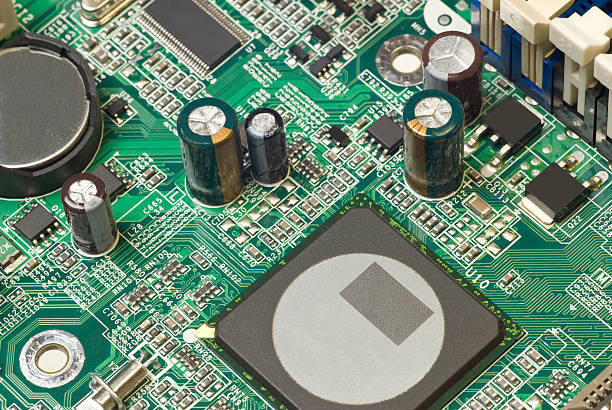

PCB test fixtures provide essential connections for precise testing, ensuring PCBs meet design specs and allowing seamless production and quality control.

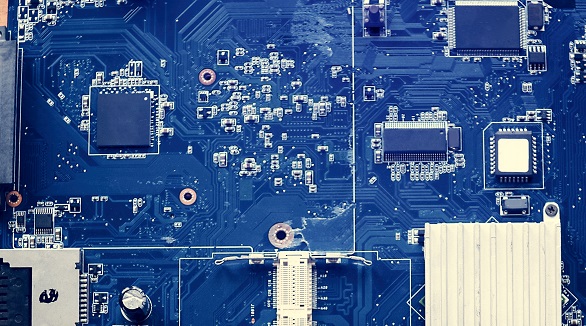

CTI measures PCB material's resistance to electrical tracking, ensuring safety and reliability in electronic circuits, crucial for design and manufacturing.

Effective electronic packaging ensures protection, efficiency, and reliability, minimizing risks from environmental hazards and supporting manufacturing processes.

PCB reliability tests ensure performance under stress, reducing costs, enhancing product life, and meeting industry standards for quality and safety.

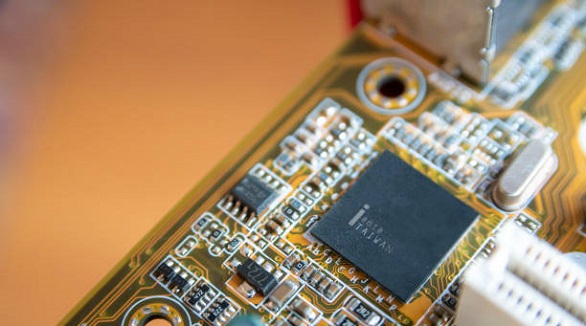

Burn-in boards are vital for testing semiconductor reliability, simulating stress to reveal defects, ensuring high-quality devices before mass production.

PCB corrosion degrades material, disrupts connectivity, and increases resistance. Prevent it with coatings, quality materials, and regular maintenance.

PCBs are essential but prone to faults. Diagnosis and repair using tools like multimeters and X-rays prevent costly repairs, ensure reliability, and improve quality.

Functional testing verifies PCB functionality in simulated environments, enhancing quality and reliability, detecting faults, ensuring performance, and cost efficiency.