PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Power and ground planes in PCBs ensure signal integrity, manage heat, and minimize EMI, crucial for efficient, high-performance electronic devices.

Tab routing in PCB manufacturing boosts efficiency and quality, ideal for non-linear shapes, offering flexibility, support, and cost-effectiveness in production.

Ceramic Substrate PCBs boost innovation with superior heat management, strength, and miniaturization, making them vital in electronics across industries.

Tab routing enhances PCB production efficiency and quality, ideal for complex shapes. It offers cost-effectiveness, flexibility, and protection, crucial for high-precision designs and panelization.

Motherboard PCBs are crucial for organizing and connecting components in electronics, ensuring efficient performance. They require detailed design and testing to meet reliability and functionality standards.

Motherboard PCBs connect key components, like CPUs and memory, in electronic devices. They require precise engineering and testing for optimal performance across consumer and industrial applications.

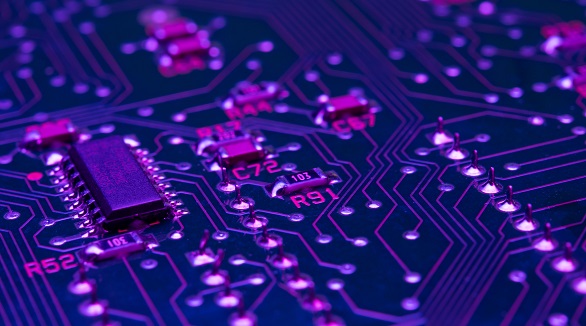

High-speed PCBs (>1GHz) are crucial for advanced electronics like 5G and data processors. Key practices include ensuring signal integrity, controlling EMI, and maintaining power integrity for reliable performance.

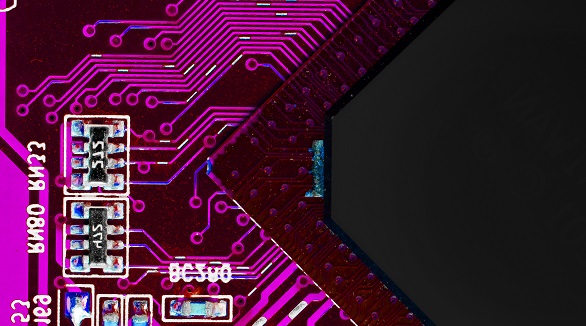

PCB panelization consolidates multiple PCBs into a larger board, improving manufacturing efficiency and reducing waste. Techniques include V-scoring and tab-routing. Proper design enhances assembly, testing, and cost-effectiveness.