PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

IPC-A-600 standard guides PCB quality through three class levels, ensuring durability and reliability for diverse applications, crucial for manufacturers.

Waterproof PCBs enhance durability and reliability in electronics for consumer, automotive, medical, and industrial sectors, using protective coatings and enclosures.

Purple PCBs offer aesthetic and technical benefits, enhancing contrast and performance. Ideal for various industries, they require careful manufacturing for best results.

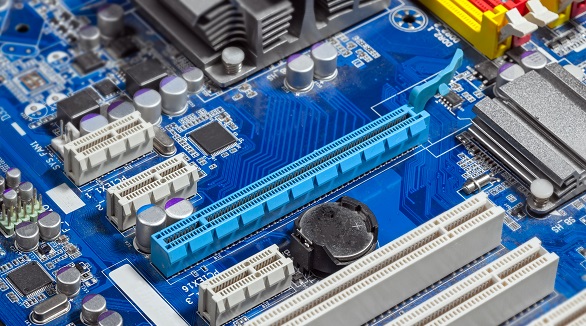

PCB standoffs secure PCBs by spacing them, aiding in thermal management and vibration absorption. They're key for durability and adaptability in electronics.

IoT revolutionizes interactions and efficiency with 30B devices by 2025, requiring secure data exchange and smart integration across various industries.

Smart lighting's growth is driven by demand for energy-efficient, customizable solutions, led by top brands like Philips Hue, LIFX, and Wyze, offering diverse options.

IPC Class 2 offers cost-effective reliability for non-critical electronics, while Class 3 ensures high-reliability for critical applications, at higher cost.

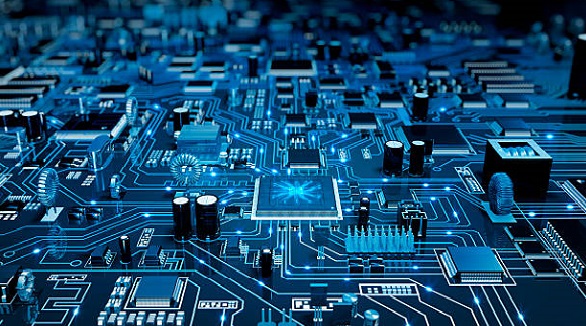

PCB simulation enhances design precision and efficiency by predicting behavior, reducing errors, and optimizing performance before prototyping, thus saving costs and time.