PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

PCB printing services are crucial for transforming complex designs into efficient parts, offering precision, cost savings, and access to advanced technologies.

Effective management of load current in PCBs ensures reliability and safety, essential for modern technology across sectors like communications and medical devices.

In the fast-evolving electronics field, PCB performance hinges on dielectric material selection, crucial for signal integrity, thermal management, and reliability.

Button plating in flex PCBs enhances flexibility, reliability, and miniaturization, meeting modern design demands for smaller, highly functional devices.

Color ultrasound enhances diagnostic accuracy with Doppler imaging for real-time blood flow analysis, aiding early detection and minimizing invasive procedures.

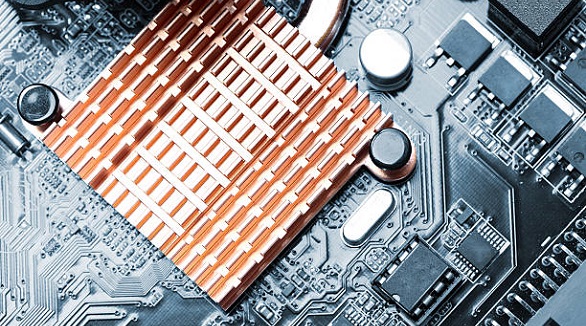

Aluminum PCBs offer cost-effective thermal management for moderate applications, while copper PCBs excel in high-performance electrical and thermal tasks.

10 oz copper PCBs offer high current capacity, improved thermal management, and durability for demanding applications in power electronics, aerospace, and military.

FR4 permittivity affects PCB signal speed and impedance. It's crucial for design, requiring careful management in high-frequency applications for reliability.