PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

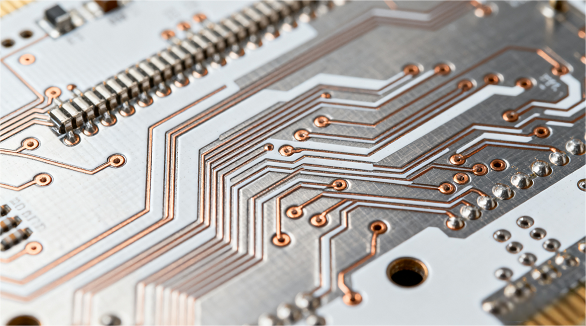

Proper trace-to-pad clearance in PCB design ensures safety, signal integrity, manufacturability, and longevity, following standards like IPC 2221 for optimal performance.

PCB routing is crucial for transforming schematics into functional layouts by ensuring electrical connectivity, signal integrity, and manufacturability amidst evolving design challenges.

Understanding open circuits is essential for maintaining electrical system safety and efficiency, utilizing advanced diagnostics and AI/ML technologies for effective management.

PCBs are essential in modern cars, enhancing performance, safety, and connectivity across systems like ADAS and infotainment, while facing design challenges.

Metal core PCBs enhance thermal management in electronics, crucial for LED efficiency and reliability, offering superior heat dissipation and compact design benefits.

Signal reflection and distortion, resulting from impedance mismatches, impact PCB performance and require strategic design, simulation, and material selection for mitigation.

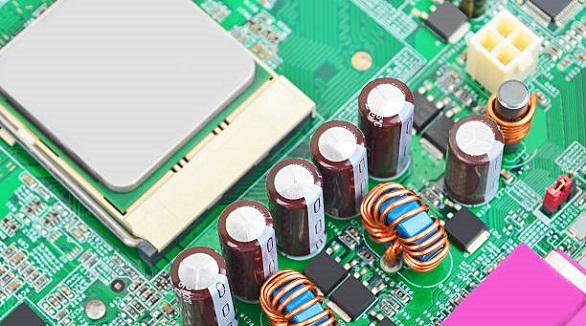

Induction PCBs optimize energy storage and signal control with components like coils and transformers, central to electronics across various applications.

Optimize PCB layout for manufacturability by ensuring proper trace clearance, via placement, and incorporating testability features, while considering manufacturing tolerances.