PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

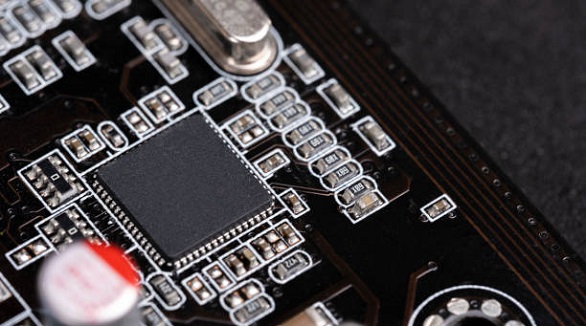

Ground loop control in PCBs is essential to prevent EMI and signal degradation, using ground planes, star grounding, and isolating signal grounds.

Mounting power supplies on PCBs optimizes space, reliability, and performance. Key factors include layout, thermal management, and mounting methods.

PCB aspect ratio, relating board thickness to via diameter, is key for quality, cost, and reliability in manufacturing, impacting plating and design.

Wetting in soldering is crucial for strong PCB bonds, ensuring durability and conductivity. Address challenges like non-wetting by optimizing materials and processes.

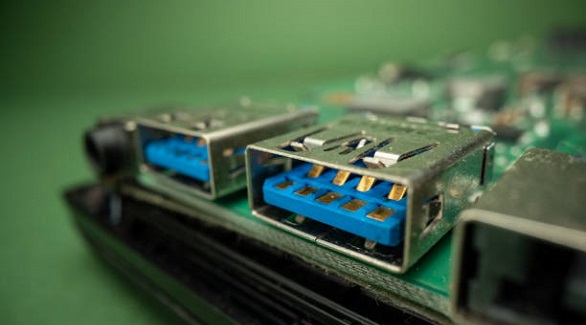

USB Host Shields expand microcontroller functionalities by enabling USB connectivity, crucial for applications in DIY projects, IoT, and prototyping environments.

Fiducial marks ensure precise PCB component placement, enhancing manufacturing accuracy, efficiency, and reliability, essential in critical sectors like aerospace.