PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Waterproof coatings protect electronics from moisture, preventing damage. Engineers must consider environment, material properties, and testing for the best fit.

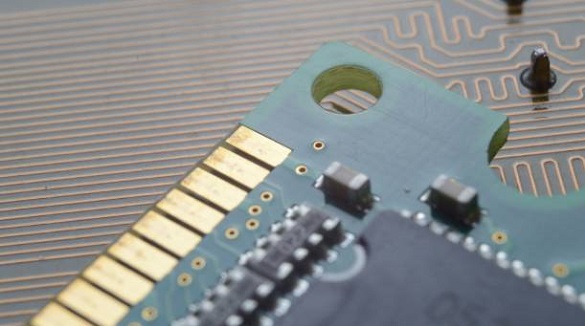

Flexible solder masks offer cost-effective flexibility, while coverlays provide durable protection for FPCs, catering to different application needs.

PCB shielding reduces EMI, ensuring reliable performance in complex electronics like smartphones and cars, crucial for enhancing electromagnetic compatibility.

Smart door locks advance home security with convenience and tech, utilizing PCBs for functions like connectivity and access, critical to smart home growth.

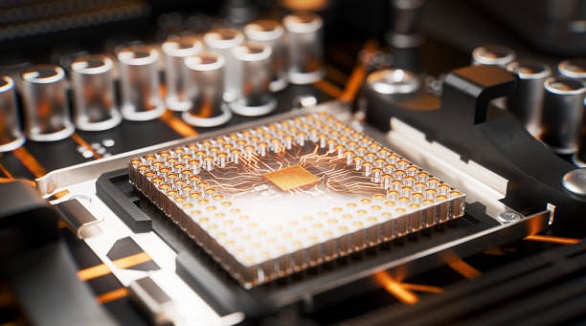

In the fast-evolving electronics field, PCB performance hinges on dielectric material selection, crucial for signal integrity, thermal management, and reliability.

Button plating in flex PCBs enhances flexibility, reliability, and miniaturization, meeting modern design demands for smaller, highly functional devices.

Package on Package (PoP) assembly stacks semiconductor devices vertically, enhancing space efficiency and performance in electronics with design flexibility.

10 oz copper PCBs offer high current capacity, improved thermal management, and durability for demanding applications in power electronics, aerospace, and military.