PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

PCB tombstoning, caused by uneven soldering due to factors like pad design and component placement, disrupts circuits but can be mitigated through precise control and optimization.

Waterproof coatings protect electronics from moisture, preventing damage. Engineers must consider environment, material properties, and testing for the best fit.

PCB tolerances ensure PCB reliability and performance by managing allowable variations in dimensions and materials, crucial for manufacturability and quality.

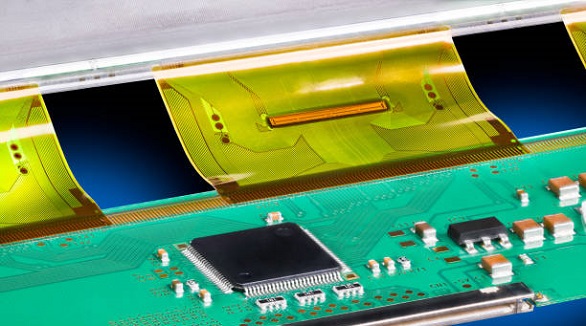

Flexible solder masks offer cost-effective flexibility, while coverlays provide durable protection for FPCs, catering to different application needs.

Serial numbers on PCBs are crucial for traceability, quality control, warranty support, and inventory management, ensuring compatibility and efficient device management.

Current limiting circuits are crucial in PCB designs, preventing overcurrent damage and ensuring safe, reliable operation across various electronic applications.

Start-stop circuits efficiently control devices, enhancing safety and performance in industrial and consumer applications through simple push-button mechanisms.

Ground loop control in PCBs is essential to prevent EMI and signal degradation, using ground planes, star grounding, and isolating signal grounds.