PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Populated circuit boards integrate electronic components for efficiency and reliability, utilizing SMT and THT for diverse applications across industries.

SMDs enhance compact, efficient PCB designs, streamline production, and boost performance in electronics by enabling high-density layouts and automated assembly.

Choose 1000 lumens for moderate brightness and energy efficiency in smaller spaces; opt for 1500 lumens for brighter coverage in larger areas.

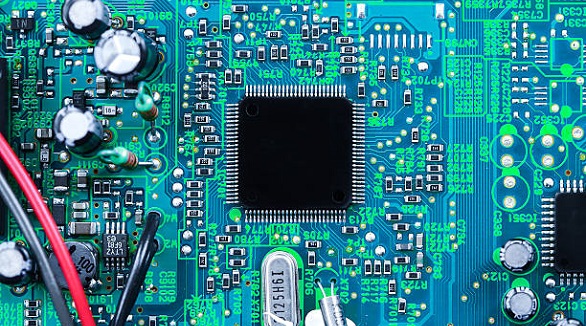

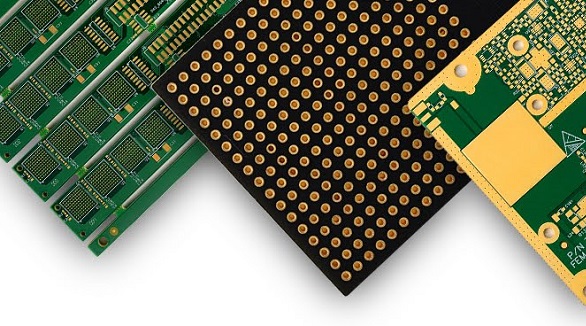

PCB pads connect components on circuit boards. Understanding through-hole, surface-mount, and BGA pads is key for effective PCB design and manufacturing.

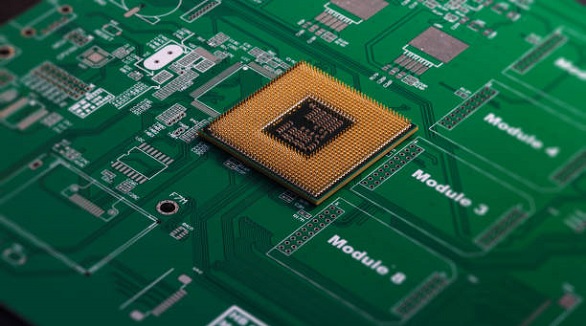

Effective PCB design ensures reliable electronics by optimizing component placement, connections, and testing, enhancing performance and longevity.

PCB test coupons simulate board elements for reliability checks, detecting early issues to ensure quality and performance before mass production.

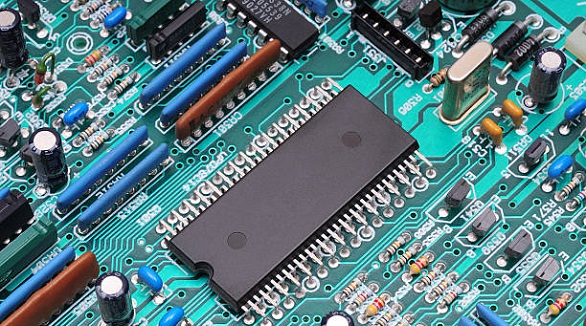

One is a bare circuitry board, and another has all the components and is functional: PCB stands for Printed Circuit Board, and PCBA stands for Printed Circuit Board Assembly. PCB acts like a base, and components are assembled on it at a later stage through various methods in PCBA, such as SMT and Thru-Hole Technology.

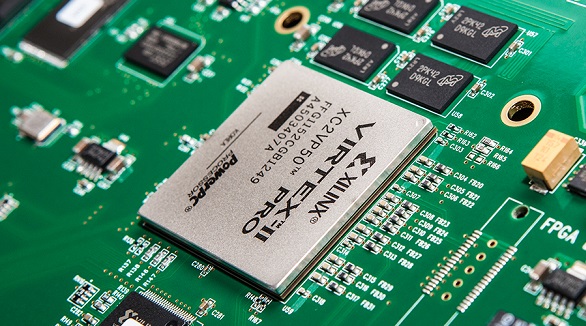

Ball Grid Array (BGA) components, such as PBGA, CBGA, CCGA, TBGA, and CSP, provide high I/O density, improved reliability, and high-quality electrical and thermal performance. Quality assembly and functionality are assured since advanced soldering and inspection methods are required, like AXI and AOI. Proper storage and handling shall guarantee the performance of the devices.