PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

BGAs are vital for compact, high-functionality devices, but demand meticulous routing to overcome design challenges in reliability, manufacturability, and signal integrity.

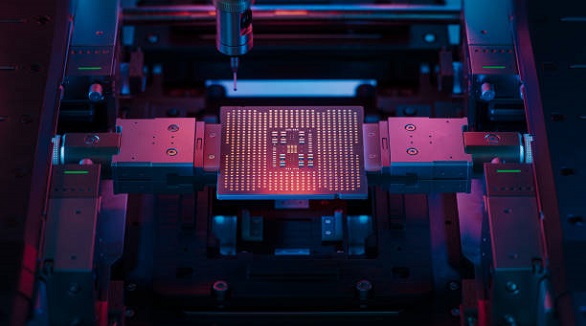

BGA rework stations offer precision, automation, and cost-efficiency, solving challenges in high-density electronics by optimizing component alignment and heating.

Smartwatches enhance life with health, connectivity, and safety features, supported by tech advances and ecosystem integration, driving market growth.

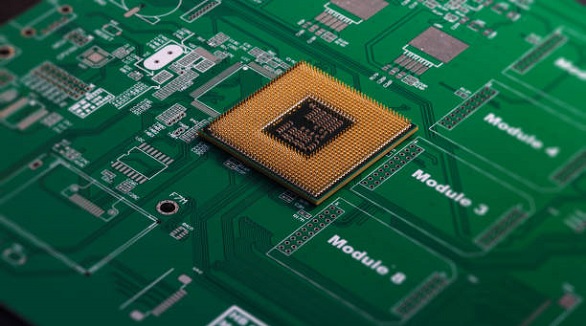

PCB pads connect components on circuit boards. Understanding through-hole, surface-mount, and BGA pads is key for effective PCB design and manufacturing.

PCB test coupons simulate board elements for reliability checks, detecting early issues to ensure quality and performance before mass production.

COB technology mounts chips directly on PCBs without packaging, reducing size and weight while improving performance and thermal management, ideal for compact devices like wearables and LEDs.

Designing PCBs for IoT demands innovation to tackle space, power, connectivity, and security challenges, ensuring robust, efficient, cost-effective devices that meet modern technological demands.

Design for manufacturability (DFM) in PCB production ensures quality, reliability, and cost-effectiveness by optimizing component selection, placement, trace routing, materials, and testing, leading to reduced costs, better products, and faster market entry.