PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

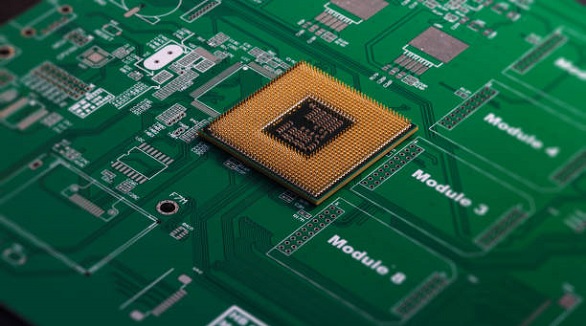

BGA rework stations offer precision, automation, and cost-efficiency, solving challenges in high-density electronics by optimizing component alignment and heating.

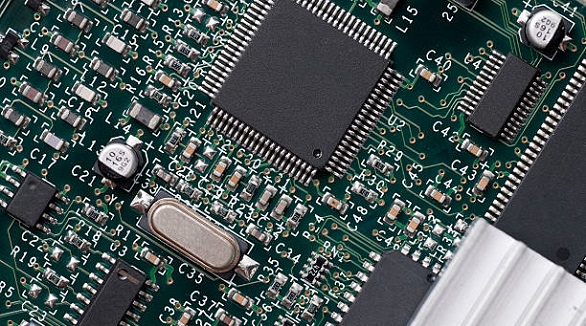

The main PCB is crucial for mounting and connecting electronic components, vital for device performance. It supports design and manufacturing innovations.

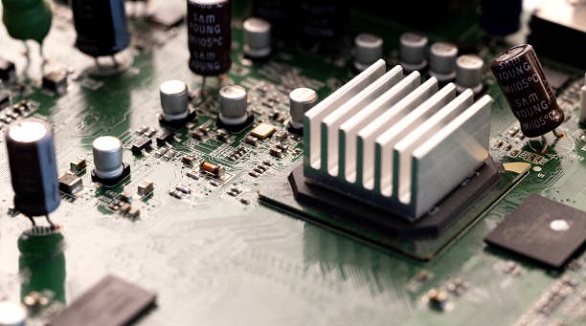

Capacitive circuits store and release energy, stabilize voltage, filter signals, and manage power flow, making them vital for modern electronic systems.

Cold solder joints result from improper soldering, impacting PCB performance. Detection and prevention via proper technique and equipment ensure reliability.

PCB pads connect components on circuit boards. Understanding through-hole, surface-mount, and BGA pads is key for effective PCB design and manufacturing.

Understanding PCB current ratings ensures safe electric flow. Optimize trace size, copper weight, and use via calculators and high-current connectors for efficient and reliable PCB designs.

Vias in PCBs connect multiple layers and come in types like through-hole, microvias, blind, and buried. Proper sizing and design optimize PCB performance and reliability, aiding advanced device development.

PCB trace technology is crucial for modern electronics, ensuring reliable and efficient signal transmission. Key elements include trace width, spacing, and material selection.