PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

IPC-A-610 ensures global standards for PCB assembly, covering component placement, soldering, labeling, and training, enhancing quality and reliability.

Superior PCBA testing ensures quality, functionality, and reliability, using diverse methods to prevent flaws, maintain standards, and enhance electronics manufacturing.

TQFP packages optimize PCB layout with space efficiency, RoHS compliance, and high reliability, addressing die shrinking and enhancing portability.

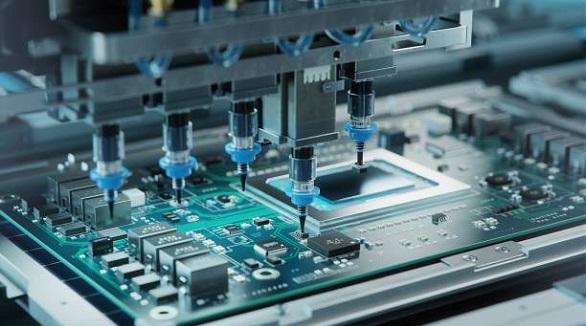

SMT revolutionizes electronics by enabling smaller, efficient, durable devices, with reduced costs and performance boosts, essential in various industries.

Ensure SMT quality through detailed design, supplier rigor, and process controls, enhanced by testing and continuous improvement for reliable, defect-free products.

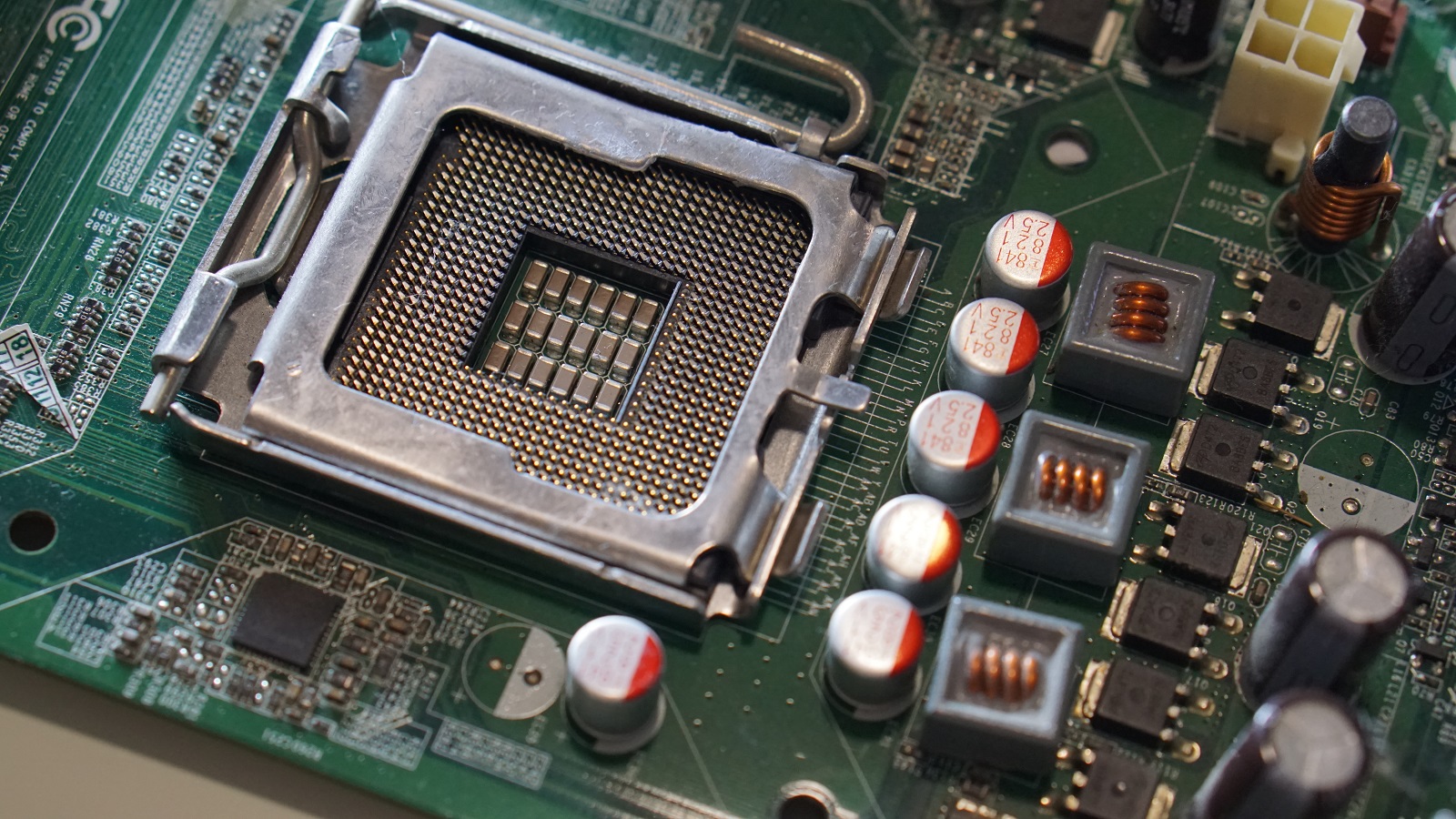

BGAs offer efficient, reliable IC connections with superior performance, comprising seven types ideal for high-performance electronics, optimizing space and thermal efficiency.

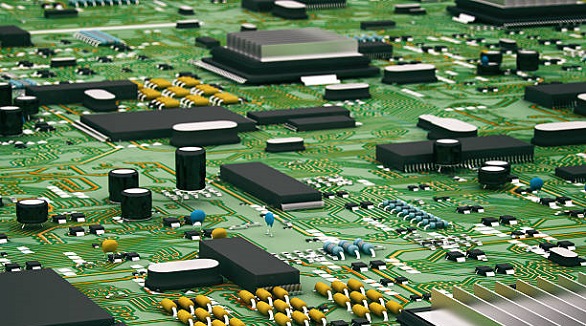

Selecting the right circuit components ensures functionality and reliability by matching specifications like voltage, current, and resistance for optimal performance.

The 3.3K resistor is vital in electronics for current regulation, is widely available, and ideal in precision circuits, ensuring stability and cost-effectiveness.