PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

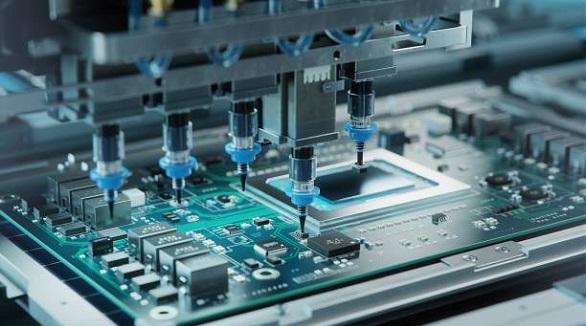

Pin in Paste (PiP) enables efficient, cost-effective PCB assembly, integrating through-hole and surface mount components in a single reflow pass, reducing costs.

Ensure SMT quality through detailed design, supplier rigor, and process controls, enhanced by testing and continuous improvement for reliable, defect-free products.

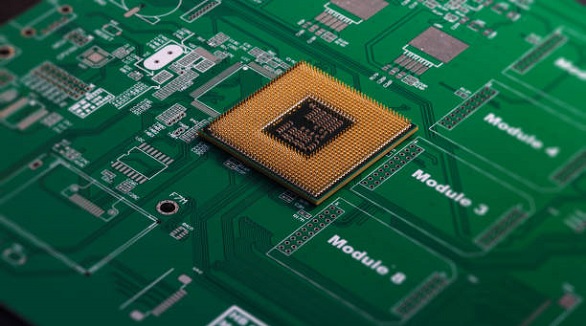

BGAs offer efficient, reliable IC connections with superior performance, comprising seven types ideal for high-performance electronics, optimizing space and thermal efficiency.

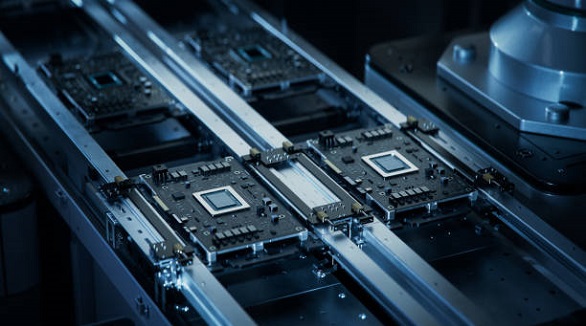

BGA rework stations offer precision, automation, and cost-efficiency, solving challenges in high-density electronics by optimizing component alignment and heating.

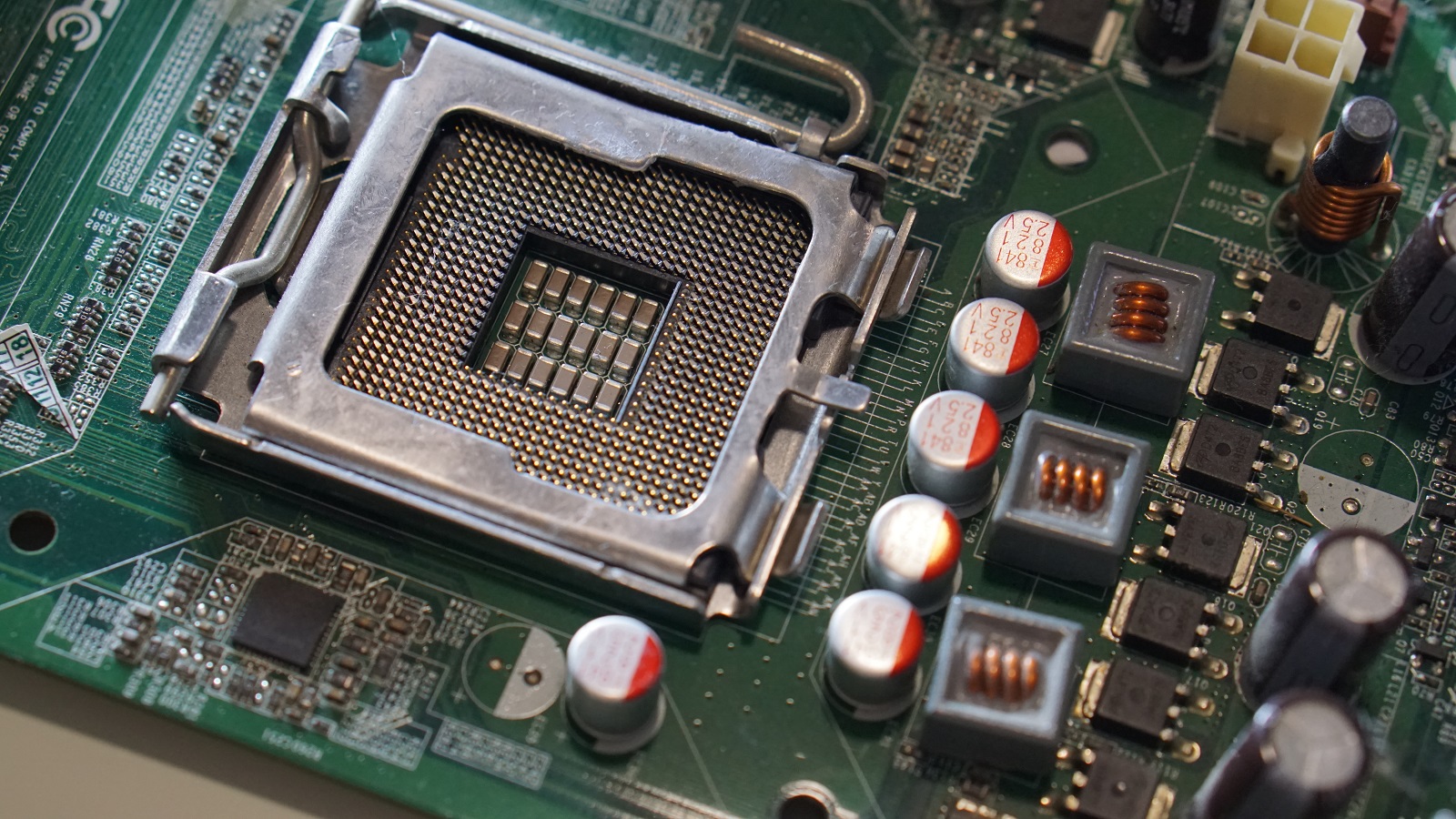

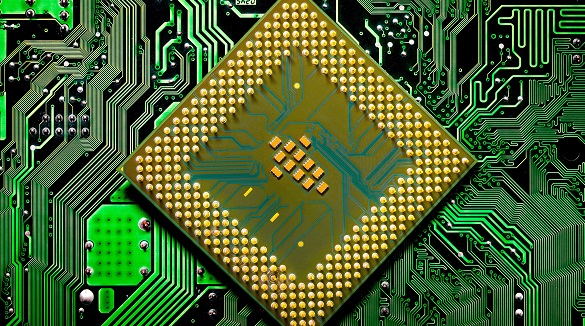

PCB pads connect components on circuit boards. Understanding through-hole, surface-mount, and BGA pads is key for effective PCB design and manufacturing.

In-Circuit Testing ensures PCB reliability by verifying component integrity and connections, with advantages in accuracy and coverage, but high setup costs.

BGA assembly, challenging due to hidden joints and warpage, requires advanced techniques, skilled training, and strategic planning for reliable PCB production and minimized defects.

BGA rework is complex, requiring skilled training, quality tools, precise thermal control, and thorough inspections to prevent costly errors and improve PCB assembly efficiency.